11 Programming of Cycles 05.91

11.10 NC-specific functions

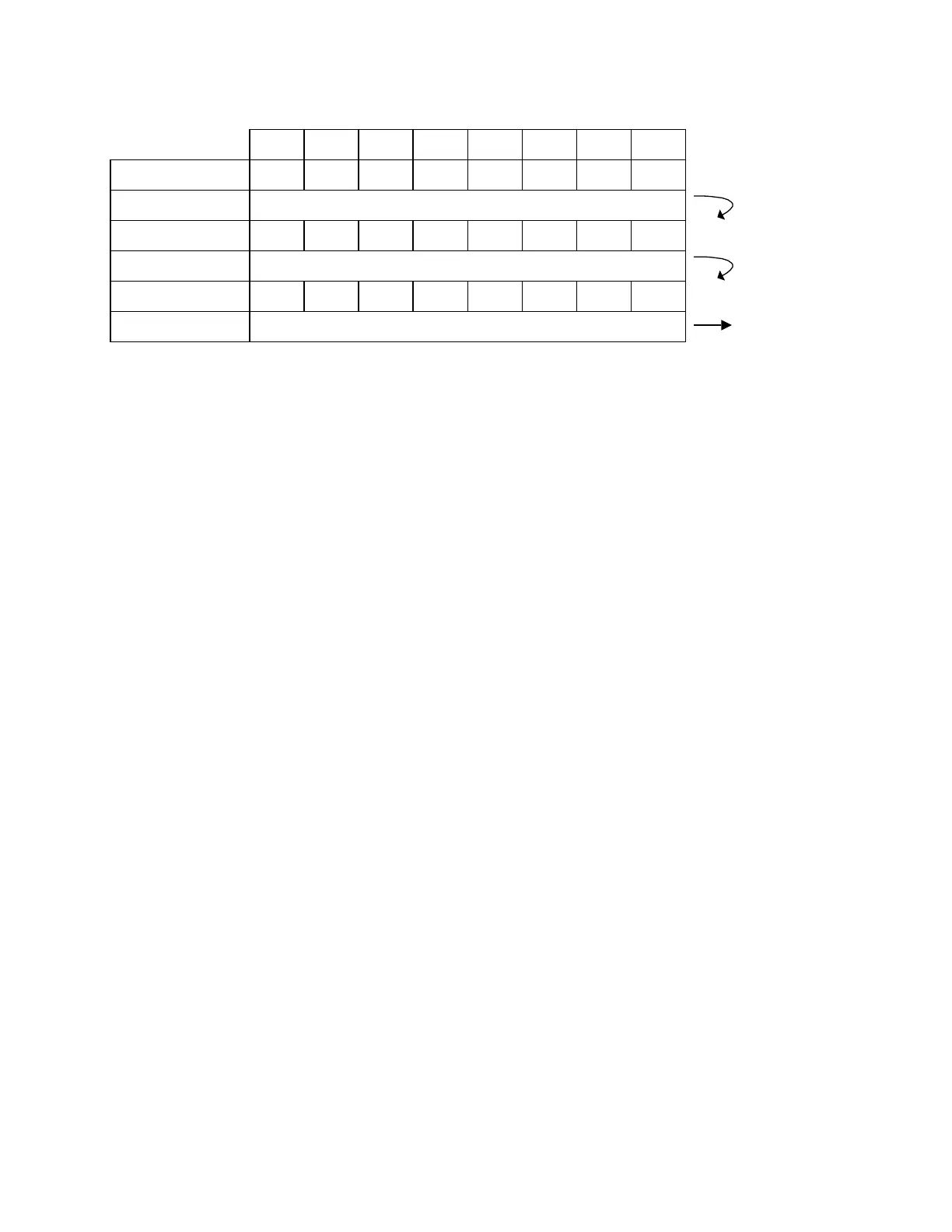

The program loop is run through until an intersection is found.

1st call @710

Rn

50

Rn+1 Rn+2 Rn+3 Rn+4 Rn+5 Rn+6 Rn+7

250 50 200 0 0 1 0

INTERSECTION FOUND ?

No:

Rm = 0

50 200 100 150 0 -50 3 0

INTERSECTION FOUND ?

No:

Rm = 0

100 150 50 100 -50 0 3 0

INTERSECTION FOUND ?

Yes:

Rm = 1

@711

2nd call @710

@711

3rd call @710

@711

After the 3rd call, the intersection in this example is found at X=90 (R71) and Z=120 (R72).

@713 <Var >

With this command, the numerical value corresponding to the safety gap of 1 mm in the

current input format is loaded in the R parameter defined with <Var> (for G70 =

0.03937 and G71 = 1). In the R parameters immediately following, the numerical value

“1” is loaded in the case of radius programming and “2”in the case of diameter pro-

gramming. The permissible parameter range for <Var> is R0 to R98 and R900 to R998.

@714

With this command, “STOP-DEC”, block preparation (decoding) is stopped until the buffer

is empty.

When the program is being executed, several program blocks are decoded in advance in

the control and loaded into the buffer of the NC. As a result, program execution is faster,

but together with certain NC commands (reading of actual values, measurements, data

transfer NC-PLC) this can lead to errors occurring in the course of the program. By

means of the STOP-DEC command (stop decoding), the advance decoding of NC blocks

written after this command is stopped until the block containing the STOP-DEC command

has been executed. This results in the buffers being emptied and information required in

the next NC blocks being made available.

The STOP-DEC instruction must be programmed for the following information from the

interface control, provided it is required in the next NC blocks:

• Machine data

• Setting data

• Tool offsets

• Zero offsets

• R parameters

• “Mirror” signal

• Axis/spindle converter

The STOP-DEC command must be programmed in its own channel each time before

reading actual values and after each measurement.

11–48

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0HD02

SINUMERIK 880, (PG)

Loading...

Loading...