05.91 9 Tool Offsets

9.8 Tool offsets for angle cutter

9.8 Tool offsets for angle cutter

As opposed to the end mill, an angle cutter requires an additional length compensation located

in the plane of the cutter radius compensation. Free axis selection must always be used with

preparatory function G16.

Function G16 is followed in this instance by four axis addresses:

1st and 2nd axis address: Plane in which the cutter radius compensation is to be active

3rd axis address: Standard length compensation as in the case of the end mill

4th axis address: Additional length compensation in the cutter radius plane.

The third and fourth axis addresses can be given a negative sign to reverse the direction of

compensation.

The number “30” must be entered under P1 (tool type).

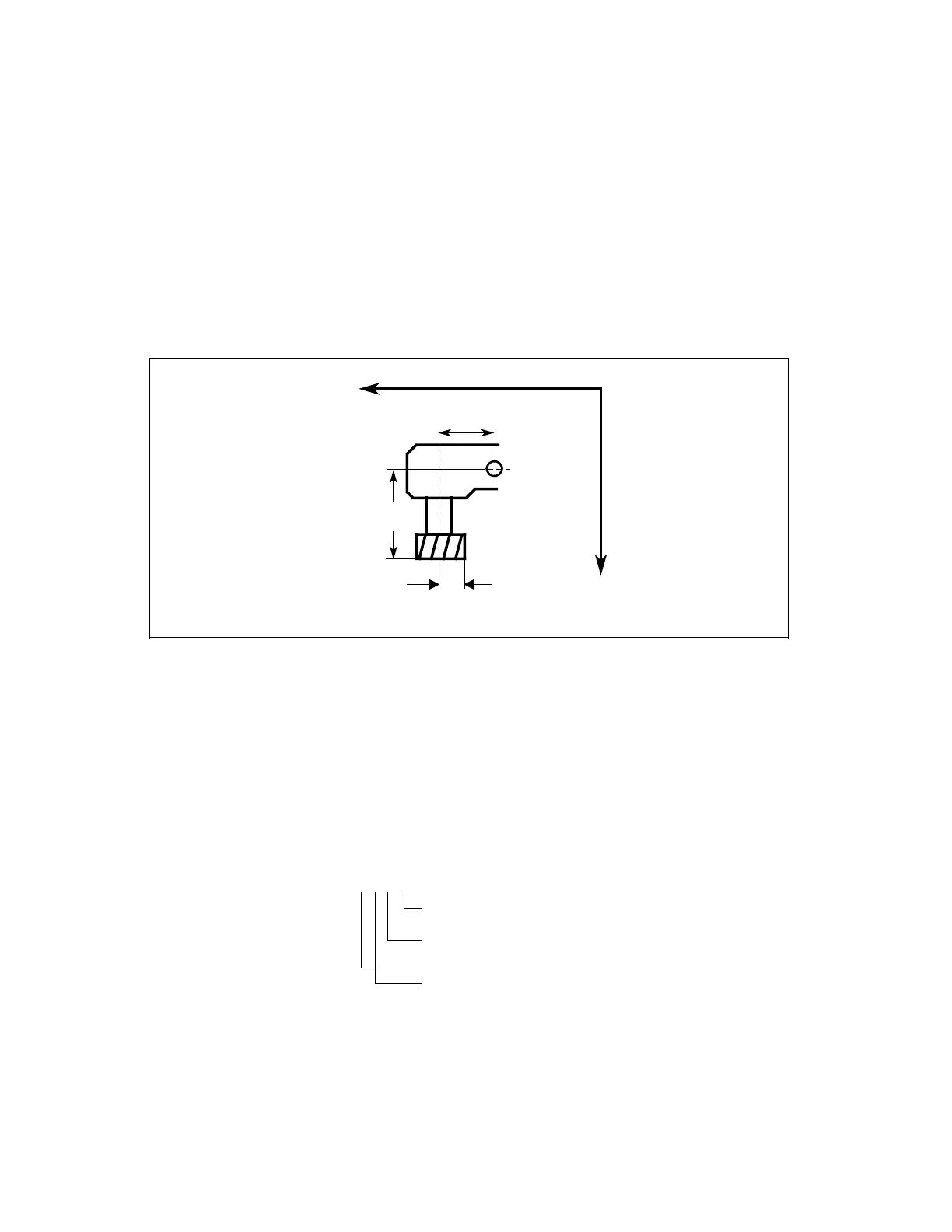

Length 2

X

Z

Radius

Length 1

P1 : Tool type (enter:30)

P2 : Geometry, length 1

P3 : Geometry, length 2

P4 : Geometry, cutter radius

P5 : Wear, length 1

P6 : Wear, length 2

P7 : Wear, cutter radius

Compensation

assignments: G16 X Y Z X

Geometry length 2 (additional length compensation)

Geometry length 1 (standard length compensation

as in the case of end mill)

Plane, in which the cutter radius compensation is to

be active

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0HD02 9–13

SINUMERIK 880, (PG)

Loading...

Loading...