4 Programming of Motion Blocks 05.91

4.2.1 Linear interpolation G01

4.2.1 Linear interpolation G01

The tool must travel at a set feedrate along a straight line to the target position whilst

machining the workpiece at the same time. The control calculates the tool path by means of

linear interpolation.

Linear interpolation effects motion

• in one axis direction (linear axis or rotary axis),

• from the starting position to the target position programmed using absolute or incremental

position data,

• at the programmed feedrate,

• at the programmed spindle speed.

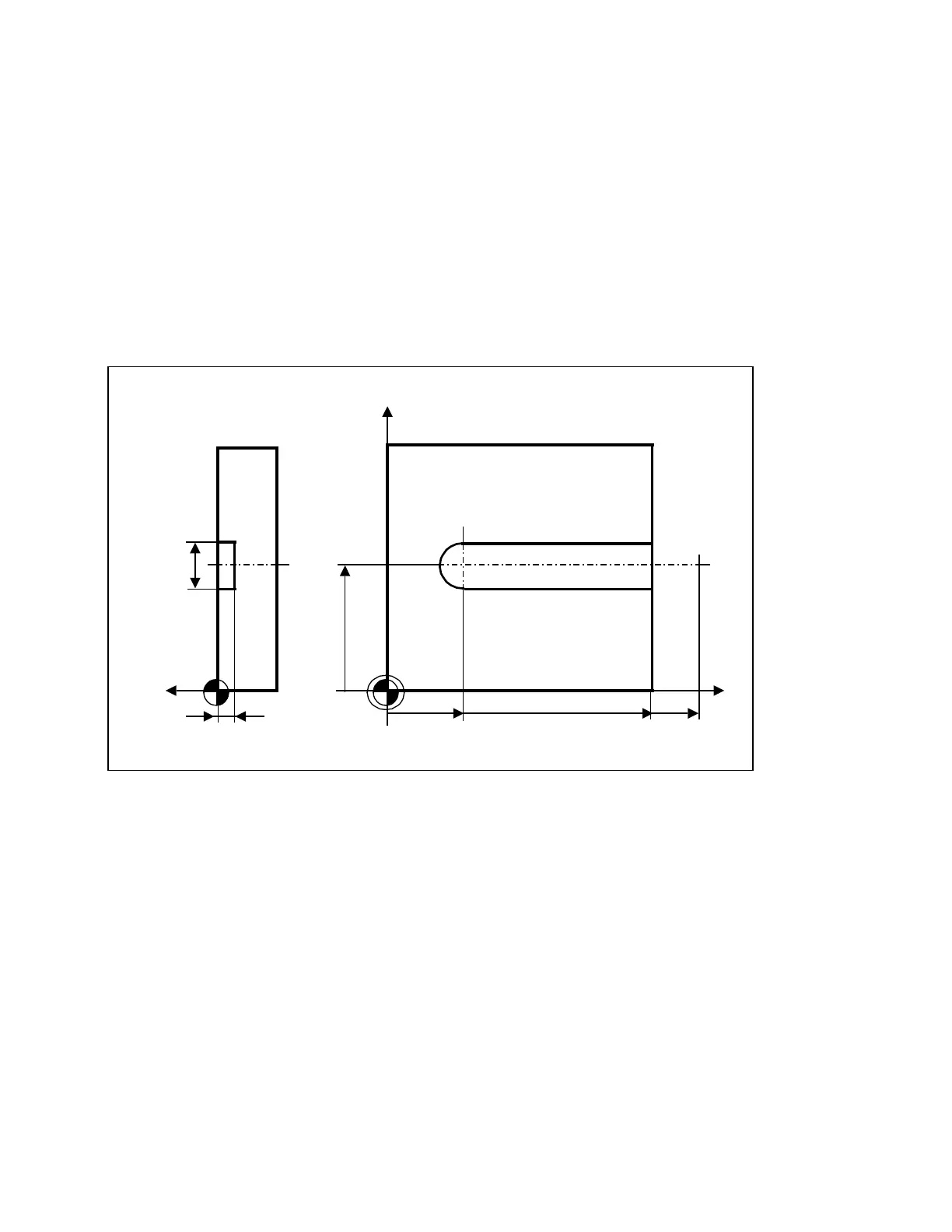

Example of paraxial milling:

5

10

0

Y

•

•

60

Z

25

P02

20 70

X

0

P01

•

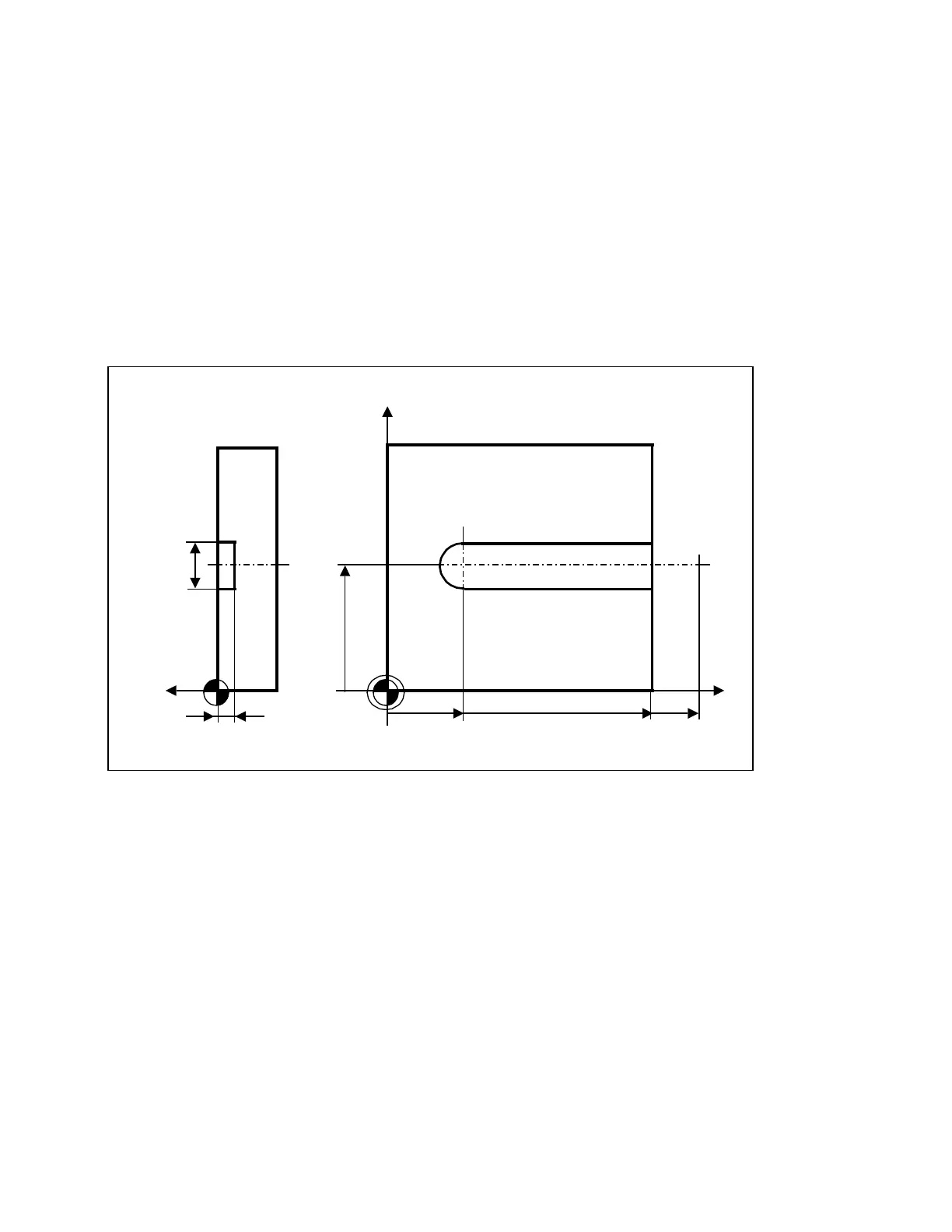

% 15

L

F

N05 G00 G90 X70 Y25 Z1 S800 M3

L

F

N10 Z-5

L

F

N15 G01 X20 F150

L

F

N20 G00 Z100

L

F

N25 X-25 Y50

L

F

N30 M30

L

F

N05 Spindle on, tool rapid traverse to P01, clockwise rotation at 800 rev/min

N10 Infeed in Z

N15 Tool traverse P01 to P02, feedrate 150 mm/min

N20/N25 Rapid traverse retraction

N30 End of program

4–4

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0HD02

SINUMERIK 880, (PG)

Loading...

Loading...