01.93 2 Fundamentals of Programming

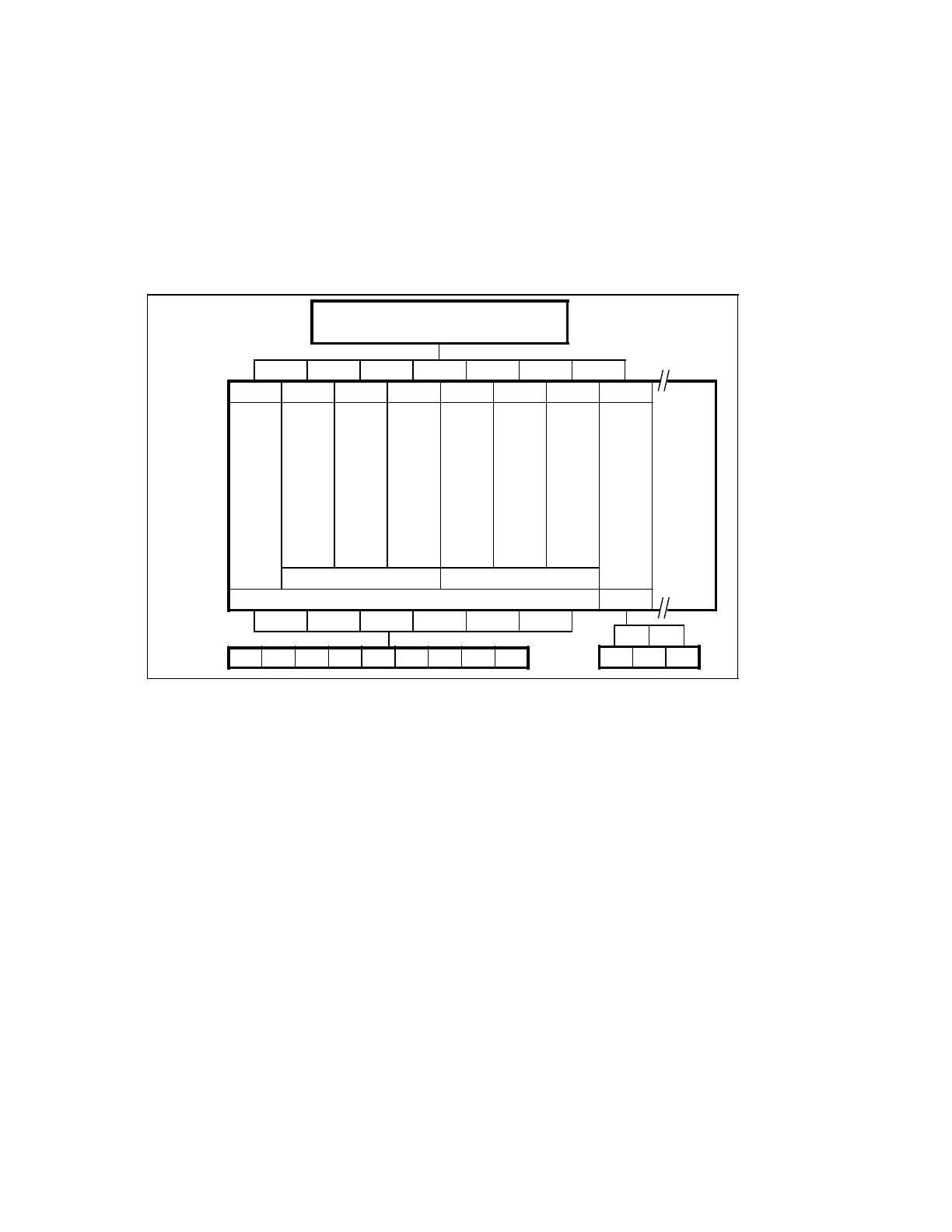

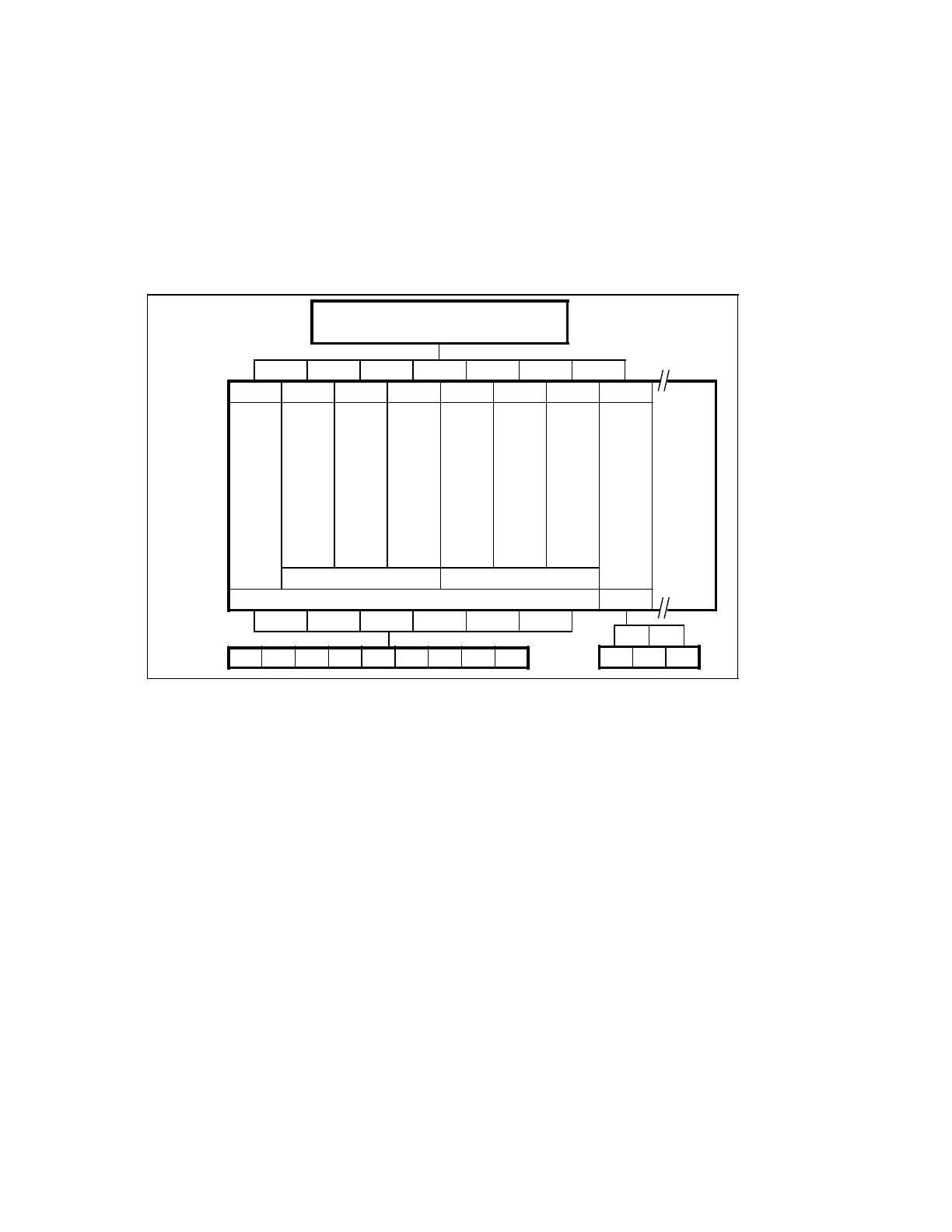

2.9 Channel-specific programming

The machine units

• Slide 1, main spindle, auxiliary spindle

• Turret 1,

• Slide 2,

• Turret 2 and

• Loader

can be allocated to the channels of the SINUMERIK 880 according to the following scheme:

Channel structure: Programmable allocation of channels

Max.

16 chan-

nels with

SINU-

MERIK

880,

SW 6

Mode

group >

Axes/

spindles

Central

part program memory

1 2 3 4 5 6 7 8

X1

Z1

S1

C

S2

Turning

and

milling

T1

Turret

1

X2

Z2

(S1)

T2

Turret

2

Q1

Q2

Q3

Loader

Slide 1 Slide 2

1 2

X1 Z1 S1 C S2 T1 X2 Z2 T2 Q1 Q2 Q3

Channel

A mode group contains those channels that, due to the operational sequence, must always

work simultaneously in the same mode. Within the mode group, any axis can be programmed

in any channel. In the above example, the loader has been assigned an own mode group. This

assignment permits Setting-up operation of the loader while workpieces are being

produced.

In addition to the 5 channels in which the programs for controlling the working units are run, 3

channels are reserved to be able to include future add-ons such as automatic tool retraction

in the case of tool breakage or coordination programs.

In the AUTOMATIC basic display, each channel is given its program number.

The channel structure allows the programs of the various channels to be processed

simultaneously and asynchronously. If synchronization is required it can be performed via the

PLC.

In each mode group as many axes can be traversed simultaneously in Jog mode as there are

channels for the mode group.

© Siemens AG 1991 All Rights Reserved 6ZB5 410-0HD02 2–19

SINUMERIK 880, (PG)

Loading...

Loading...