Functional Description

AP05

Date: 22.08.2022 Art. No. 90885 Mod. status 108/22 Page 23 of 50

3.6.2.2 Error counter

There is an associated error counter for each error type. The error counters are reset when the

factory settings are restored. The number of error types and the respective number of errors

can be output via the IO-Link interface (see chapter 4.6).

3.6.3 Corrective actions

If applicable, calibration

required after error correction

and acknowledgment.

Restart device, restore factory

settings, parameterize again.

Table 19: Corrective actions

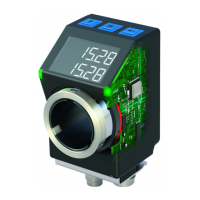

3.7 Adjustment run (already carried out at the factory for AP05)

The AP05 position indicator is fully functional at delivery. For a complete description of the

product, the adjustment process is described here.

When you enter the CODE 00100 or via the corresponding IO-Link SystemCommand, the

adjustment process is started (see chapter 3.3.1.9 and 5.3).

Display: 1

st

line "ADJUST"

2

nd

line "100" this value can vary by ±1.

Now the shaft must be rotated clockwise by a few millimeters (speed <<1 rpm).

The value changes in the positive direction up to "103" in the lower line.

If this value is exceeded in the end, the adjustment process has been completed. The AP05 is

back in normal operation and shows the corresponding display. If values above "103" are

displayed during the adjustment, the travel speed must be reduced during the adjustment.

It is not unusual for the position value initially not be displayed after the adjustment run;

"L" is displayed instead of the value. The display must then be calibrated

(see chapter 3.4).

Loading...

Loading...