3-8

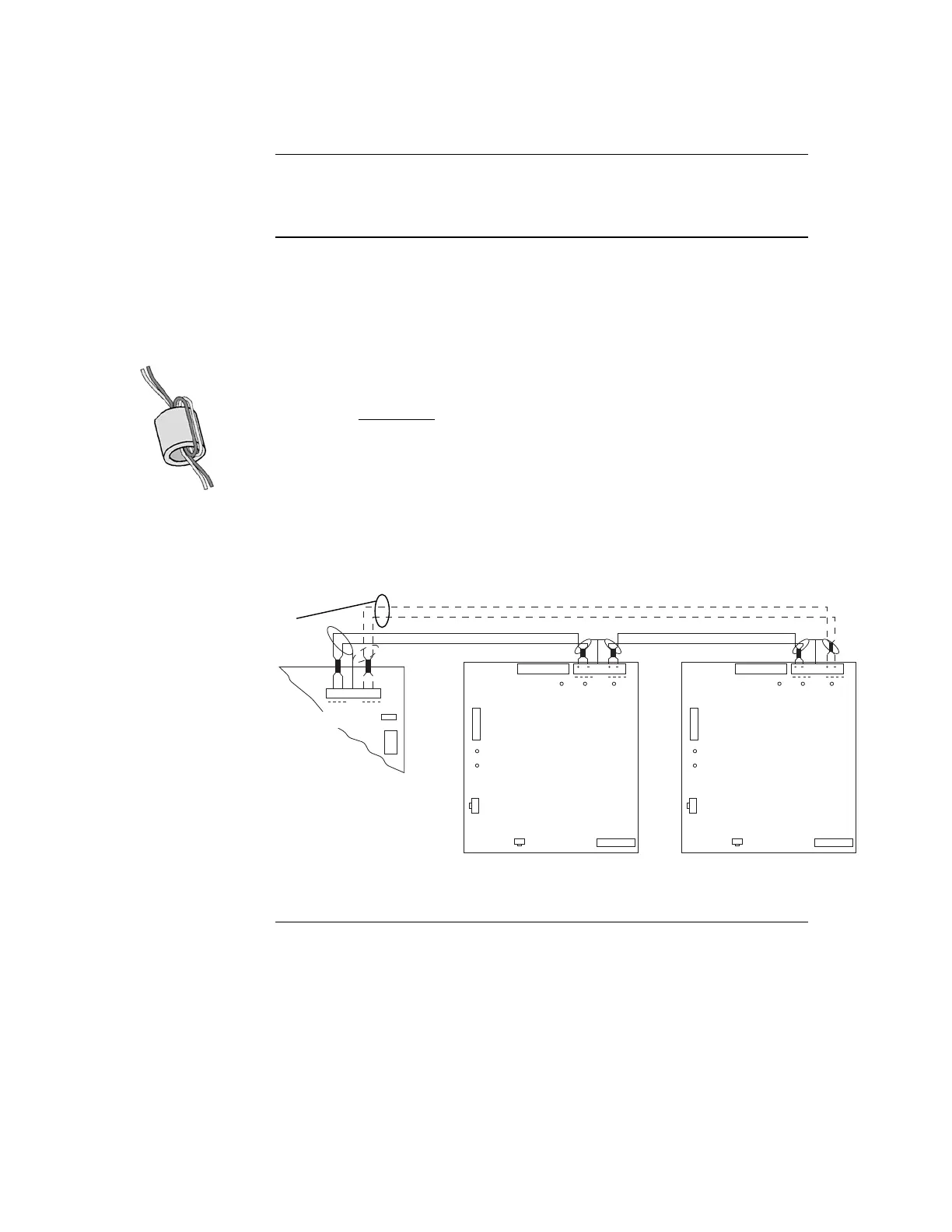

The TIC must be connected to the host panel via RUI cabling. This section explains how

to wire the two together, and how to set up a system with multiple transponders connected

to the same host panel.

RUI cabling can be accomplished either through Class A (loop) or Class B (spur) wiring.

Class A wiring allows transponder cabinets to communicate with the host panel even in

the event of a single open or short circuit somewhere in the loop.

Class B wiring allows “T” tapping, and therefore requires less wiring run per installation

than Class A.

If the transponder(s) have more than 40 detectors connected to them in total, Class A

(loop) wiring must be used to meet the requirements of AS 1670.1.

RUI wiring does not require end-of-line resistors, because each TIC communicates

directly to the CPU.

Note: Use the supplied ferrite beads with TICs. Loop wires once through

the ferrite bead(s) as shown in Figure 3-5.

The illustration below shows both types of wiring.

{xe "MINIPLEX wiring: Class B"}{xe "MINIPLEX wiring: Class A"}

TRANSPONDER INTERFACE

ASSY 566-094

MSB

LSB

LED1

ADDRESS

LED3

PRI

B+ B- SHLD A+ A-

SEC

RUI

SHLD

LED4 LED5

LED2

P1

P2 P3

RUI

P9

P1

123

TRANSPONDER INTERFACE

ASSY 566-094

MSB

LSB

LED1

ADDRESS

LED3

PRI SEC

RUI

SHLD

LED4 LED5

LED2

P1

P2

Figure 3-5. TIC Wiring to the Host Panel

RUI Wiring (4100ES)

Overview

Wiring

Configurations

Figure 3-4

The Ferrite Bead

DASHED LINES ARE FOR

CLASS A OPERATION

Wire size must be

between 18 AWG (0.8231 mm

2

)

and 12 AWG (3.309 mm

2

).

Maximum wiring distance: 760m.

Maximum “T” tapping length: 3000m.

Maintain correct polarity on terminal

connections.

Do not loop wires under terminals.

CPU

MOTHERBOARD

566-227

Loading...

Loading...