TECHNICAL CHARACTERISTICS

AB16EJ Plus Maintenance Manual 21

© Mar. 2023

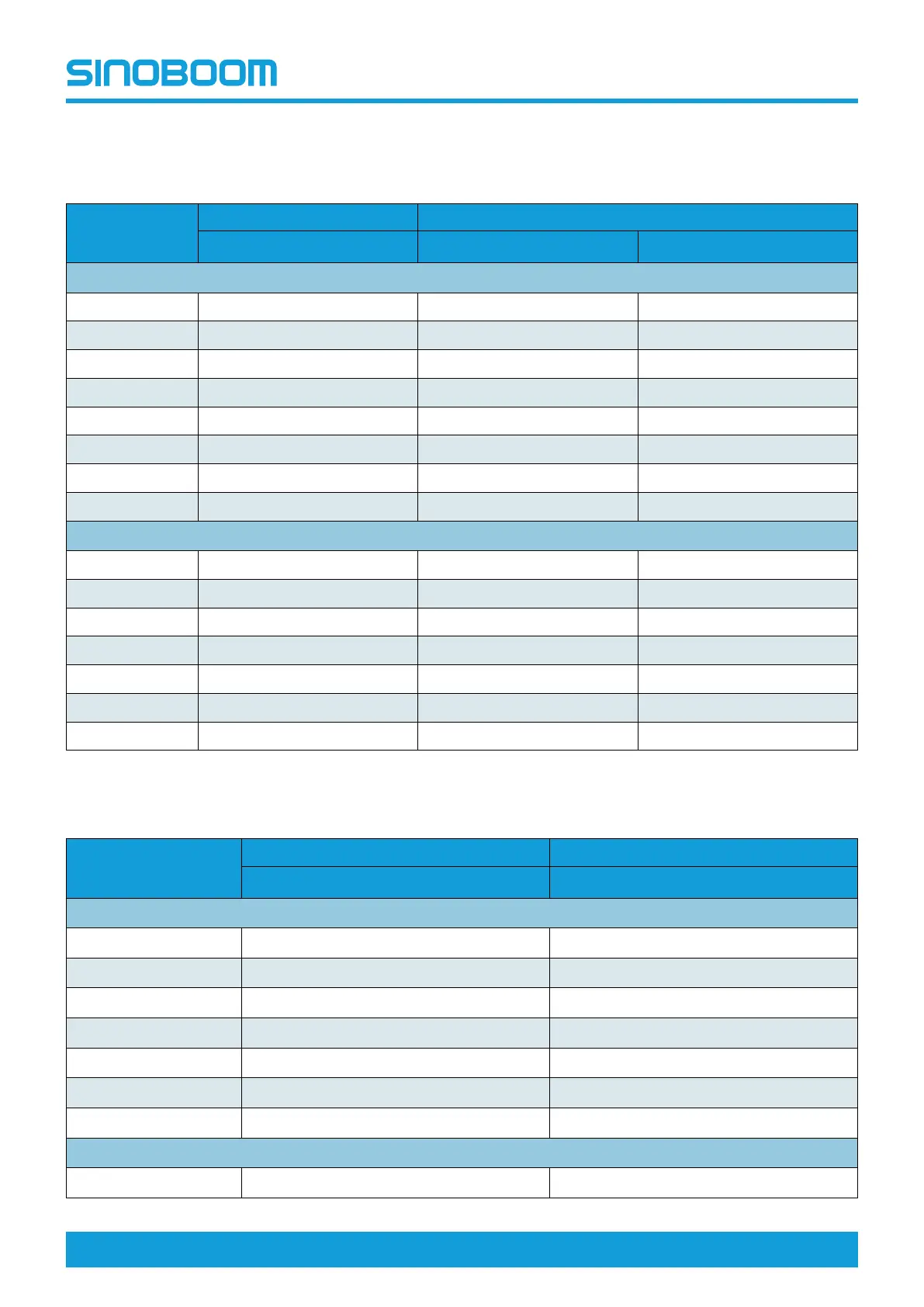

The hydraulic fitting with British Standard Pipe (BSP) thread must be removed or installed as per the following

torque.

Table 3-22 Hydraulic Fitting Torque-British Standard Pipe (BSP)

Thread size

Installed to aluminum Installed to steel

ED, O-ring + Circlip ED, O-ring + Circlip O-ring

L (light-duty)

G1/8A 20±1Nm (15±1ft-lb) 20±1Nm (15±1ft-lb)

-

G1/4A 35±2Nm (26±2ft-lb) 40±2Nm (30±2ft-lb)

-

G3/8A 50±3Nm (37±2ft-lb) 75±5Nm (55±2ft-lb)

-

G1/2A 75±5Nm (55±2ft-lb) 95±6Nm (70±4ft-lb)

-

G3/4A 120±8Nm (89±6ft-lb) 185±12Nm (136±9ft-lb)

-

G1A 180±10Nm (133±7ft-lb) 320±20Nm (236±15ft-lb)

-

G1-1/4A 240±15Nm (177±11ft-lb) 450±25Nm (332±18ft-lb)

-

G1-1/2A 280±20Nm (207±15ft-lb) 540±30Nm (398±22ft-lb)

-

S (heavy-duty)

G1/4A 40±3Nm (30±2ft-lb) 43±3Nm (32±2ft-lb)

-

G3/8A 55±3Nm (41±2ft-lb) 85±5Nm (63±4ft-lb)

-

G1/2A 80±5Nm (59±4ft-lb) 120±8Nm (89±6ft-lb)

-

G3/4A 120±8Nm (89±6ft-lb) 185±12Nm (136±9ft-lb)

-

G1A 180±10Nm (133±7ft-lb) 320±20Nm (236±15ft-lb)

-

G1-1/4A 240±15Nm (177±11ft-lb) 450±25Nm (332±18ft-lb)

-

G1-1/2A 280±20Nm (207±15ft-lb) 540±30Nm (398±22ft-lb)

-

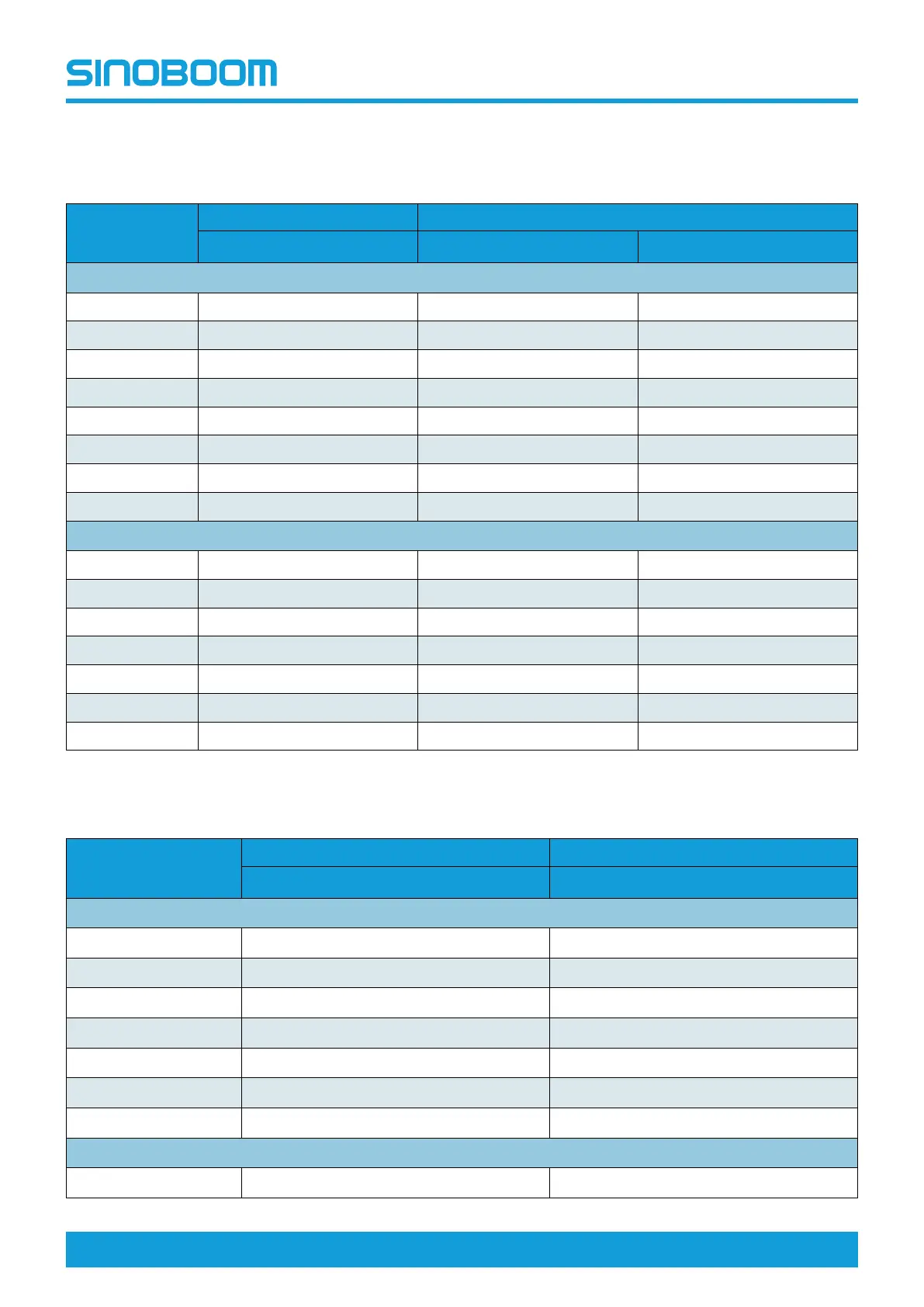

The hydraulic fitting with Unified Thread Standard (UNC/UNF) thread must be removed or installed as per the follow-

ing torque.

Table 3-23 Hydraulic Fitting Torque-Unified Thread Standard (UNC/UNF)

Thread size

Installed to aluminum Installed to steel

O-ring O-ring

L (light-duty)

7/16-20 21±2Nm (15±2ft-lb) 21±2Nm (15±2ft-lb)

9/16-18 34±2Nm (25±2ft-lb) 35±2Nm (26±2ft-lb)

11/16-12 40±3Nm (30±2ft-lb) 50±4Nm (37±3ft-lb)

3/4-16 50±3Nm (37±2ft-lb) 65±4Nm (48±3ft-lb)

7/8-14 75±5Nm (55±4ft-lb) 110±8Nm (81±6ft-lb)

1-1/16-12 110±8Nm (81±6ft-lb) 140±10Nm (103±7ft-lb)

1-5/16-12 160±10Nm (118±7ft-lb) 210±15Nm (155±11ft-lb)

S (heavy-duty)

7/16-20 21±2Nm (15±2ft-lb) 23±2Nm (17±2ft-lb)

Loading...

Loading...