© Mar. 2023 38 AB16EJ Plus Maintenance Manual

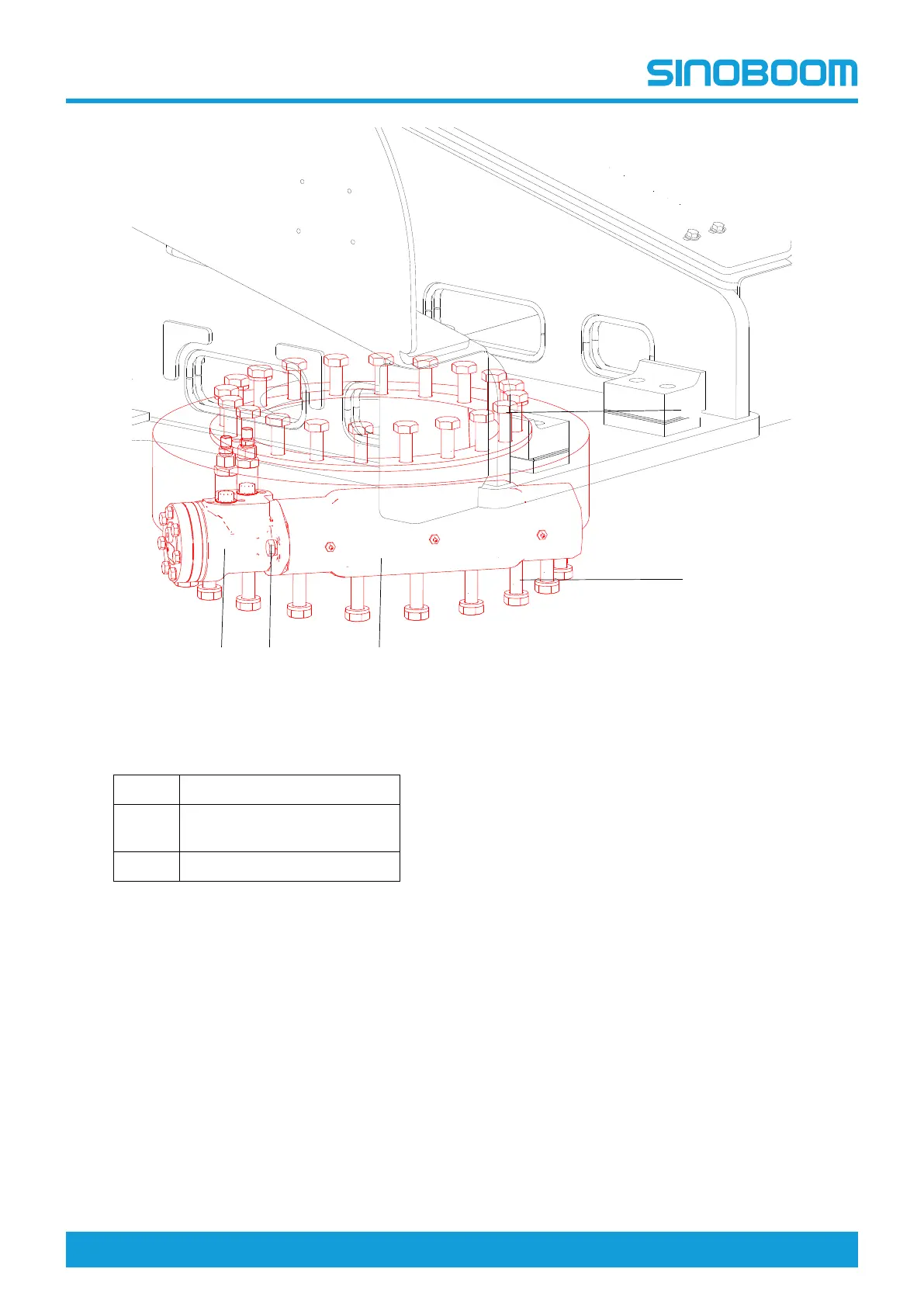

CHASSIS AND TURNTABLE ASSEMBLY

Fig 6 Diagram of slewing mechanism

Table 5-3 Slewing mechanism

No.

Description

A

Slewing bearing

(slewing reducer)

B

Slewing motor

Lubricate Slewing Bearing

Regular lubrication of slewing bearing is essential to

maintain machine uptime and extend service life. Failure

to lubricate the slewing bearing regularly may lead to

abnormal operation of the machine and accelerated

component damage. It is recommended to lubricate the

slewing bearing every 3 months or 250 hours of opera-

tion, and when the machine is operated in multiple shifts

or exposed to harsh environments, the lubrication fre-

quency and amount of lubricant should be increased

accordingly.

1. As shown in the figure below, connect the grease

nipple on the slewing bearing and the nipple at posi-

tion #1 with a hose.

2. Position the oil gun nozzle on the grease nipple at

position #1 and fill with ZL-3 lithium-based grease

which will be transported to the turntable slewing

bearing through the hose.

3. Then, rotate the turntable by 100-130mm (4-5in)

each time until the whole circle is fully lubricated.

4. Position the oil gun nozzle on the grease nipple at

position #2 and fill with ZL-3 lithium-based grease

until the worm is fully lubricated.

5. Remove excess grease.

Loading...

Loading...