CHASSIS AND TURNTABLE ASSEMBLY

AB16EJ Plus Maintenance Manual 35

© Mar. 2023

Replace Tires

Tighten the nut to the proper torque to prevent the

tire from loosening. Use a torque wrench to

tighten the fastener, if you don't have a torque

wrench, use a socket wrench to tighten the

fastener and then immediately have a service

station or dealer to tighten the fastener to the

correct torque. Over-tightening will cause the

bolts to break or permanently deform the bolt

holes in the tires.

The correct steps to replace a tire are as follows:

1. Make sure the machine is in stowed position.

2. Press the main power switch and disconnect all

power sources (such as battery charger) connected

to the machine.

3. Use a wrench to loosen but do not remove the tire

retaining nut.

4. Use a jack with sufficient load capacity to lift the ma-

chine frame to the appropriate height so that the tire

assembly is off the ground.

5. Remove the tire retaining nuts and bolts alternately,

and then remove the tire.

6. Align the mounting hole of the new tire with the cor-

responding mounting hole in the frame.

7. After applying Loctite 272 threadlocking adhesive to

the bolts and nuts, install the bolt and nuts

sequentially.

8. Tighten all nuts by hand first to prevent loosening of

the bolts and nuts. Never apply lubricant to threads

or nuts.

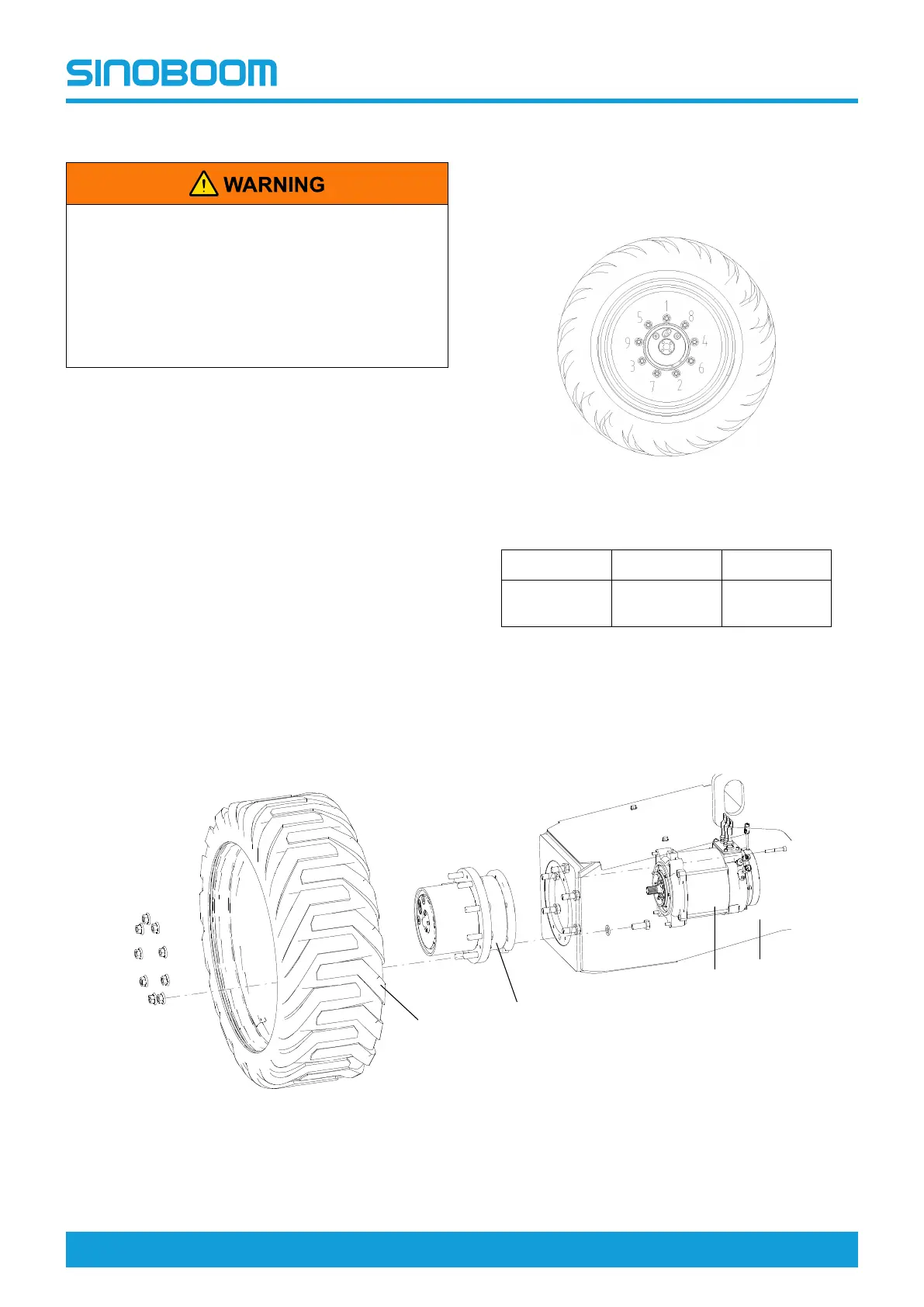

9. Then tighten the nuts step by step in the order as

shown below. Please refer to the recommended tor-

que in the table below for tightening.

Fig 2 Diagram of wheel nuts tightening sequence

Table 5-1 Table of wheel nuts tightening torque

First step

Second step

Third step

150Nm

(110ft-lb)

240Nm

(177ft-lb)

300Nm

(221ft-lb)

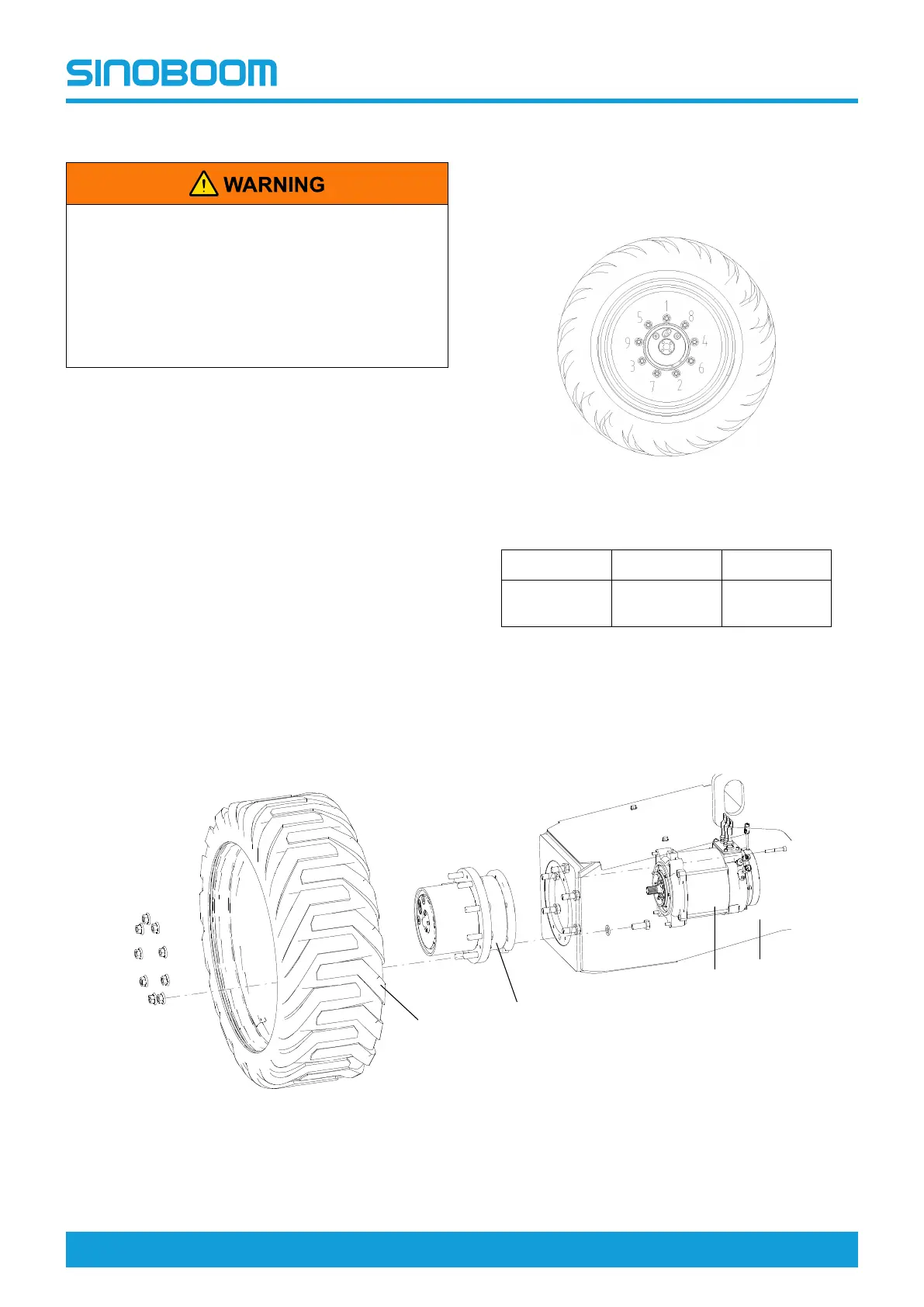

5.3 TRAVEL DRIVE DEVICE

The travel drive device is mainly composed of the travel

reducer and travel motor.

Fig 3 Diagram of travel drive device

Loading...

Loading...