© Mar. 2023 42 AB16EJ Plus Maintenance Manual

CHASSIS AND TURNTABLE ASSEMBLY

the marking line on the chassis.

3. Check the clearance between the slewing bearing

mounting surface and the chassis mounting surface

with a feeler gauge, ensuring the clearance ≤

0.2mm (0.008in).

4. Using the special high-strength washers for high-

strength bolts, fit the washer face with the mounting

surface, and apply Loctite 272 threadlocking adhe-

sive, and then install the bolts one by one by pass-

ing it through the chassis and the outer ring of the

slewing bearing.

NOTICE

• Do not reuse removed bolts and washers, and

replace with new fasteners.

• The slewing bearing is the only structural con-

nection between the chassis and the turntable,

and its replacement should meet the specifica-

tion requirements. It is highly recommended

that you use genuine accessories.

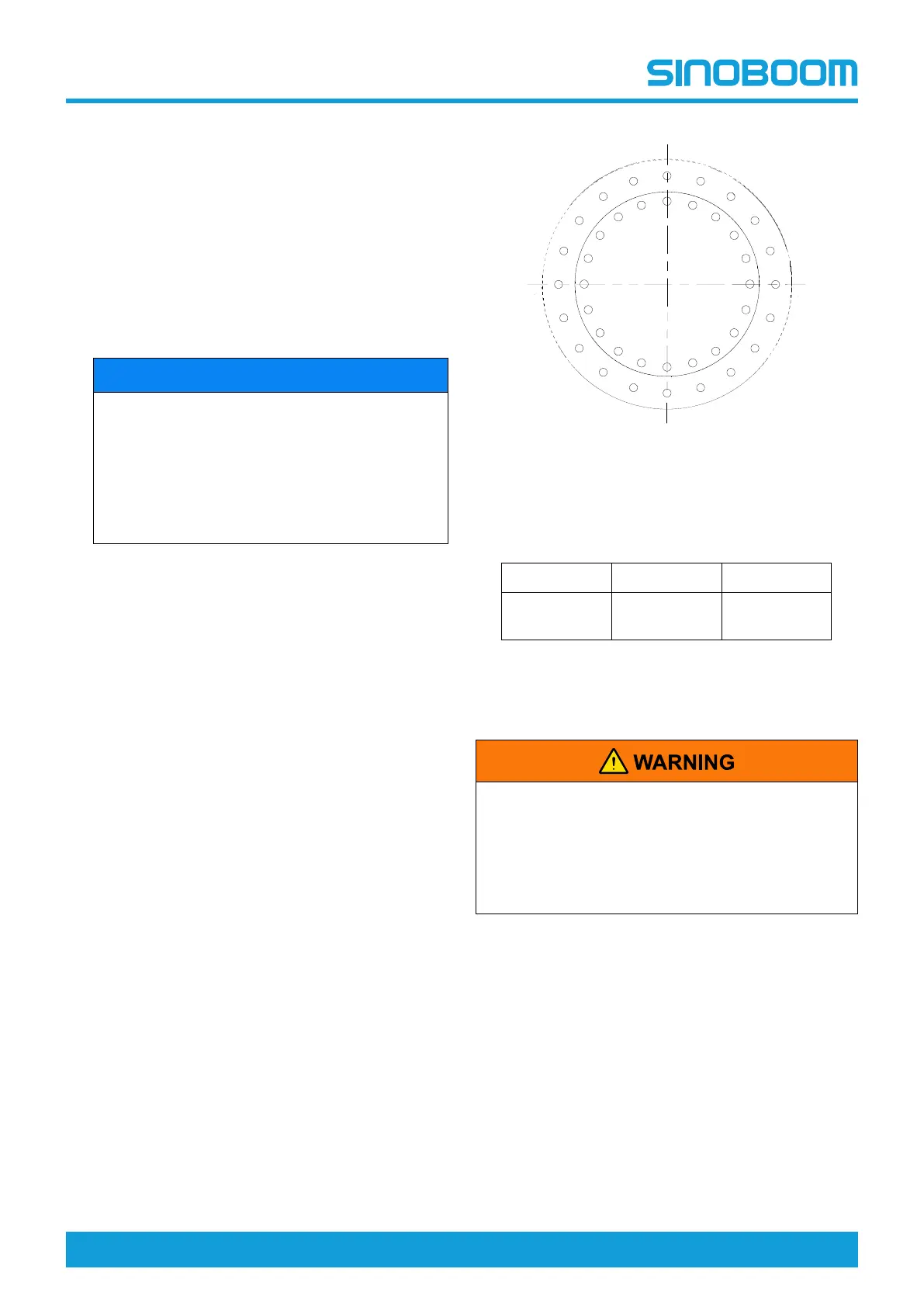

5. Then tighten the bolts in the sequence shown in the

following diagram and follow the steps in the table

below.

6. After the bolts are tightened, mark the bolt head and

its connection with an appropriate tool to facilitate

later inspection of the bolts for looseness.

7. Rotate the inner ring of the slewing bearing by hand

to ensure smooth movement.

8. Remove the lifting equipment from the slewing

bearing.

9. Lift the turntable assembly to the top of the chassis

using suitable lifting equipment, carefully lower the

turntable onto the slewing bearing, and align the in-

ner ring of the slewing bearing with the marking line

on the turntable. If replacing the slewing bearing

with a new one, make sure that the filling cup joint is

at 90° to the left-right symmetrical line of the

turntable.

10. Using the special high-strength washers for high-

strength bolts, fit the washer face with the mounting

surface, and apply Loctite 272 threadlocking adhe-

sive, and then install the bolts one by one by pass-

ing it through the turntable and the inner ring of the

slewing bearing.

11. Then tighten the bolts in the sequence shown in the

following diagram and follow the steps in the table

below.

12. After the bolts are tightened, mark the bolt head and

its connection with an appropriate tool to facilitate

later inspection of the bolts for looseness.

13. Remove the lifting equipment and reconnect the hy-

draulic hoses according to the marks before

disassembly.

Fig 11 Tightening sequence of slewing bearing

bolts

Table 5-4 Table of slewing bearing bolt tightening

torques

First step

Second step

Third step

160Nm

(118ft-lb)

270 Nm

(199ft-lb)

300Nm

(221ft-lb)

5.5 COUNTERWEIGHT

Counterweights are essential to maintain the

stability of the machine. Do not modify or remove

counterweights without the manufacturer's

written authorization. Improperly assembled

counterweights may cause the machine to tip

over, causing serious injury, death, or machine

damage.

Disassembly

1. Adjust the machine to the stowed position and make

sure the turntable is locked (if equipped with a rotary

pin, make sure the rotary pin is locked).

2. Use suitable lifting equipment to provide reliable

support for the boom and prevent the machine from

tipping after the counterweight is removed.

3. Use suitable lifting equipment to support the

counterweight.

4. Remove the bolts securing the counterweight to the

turntable.

5. Slowly remove the counterweight with the aid of the

lifting equipment.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Loading...

Loading...