© Mar. 2023

54 AB16EJ Plus Maintenance Manual

BOOM AND PLATFORM ASSEMBLY

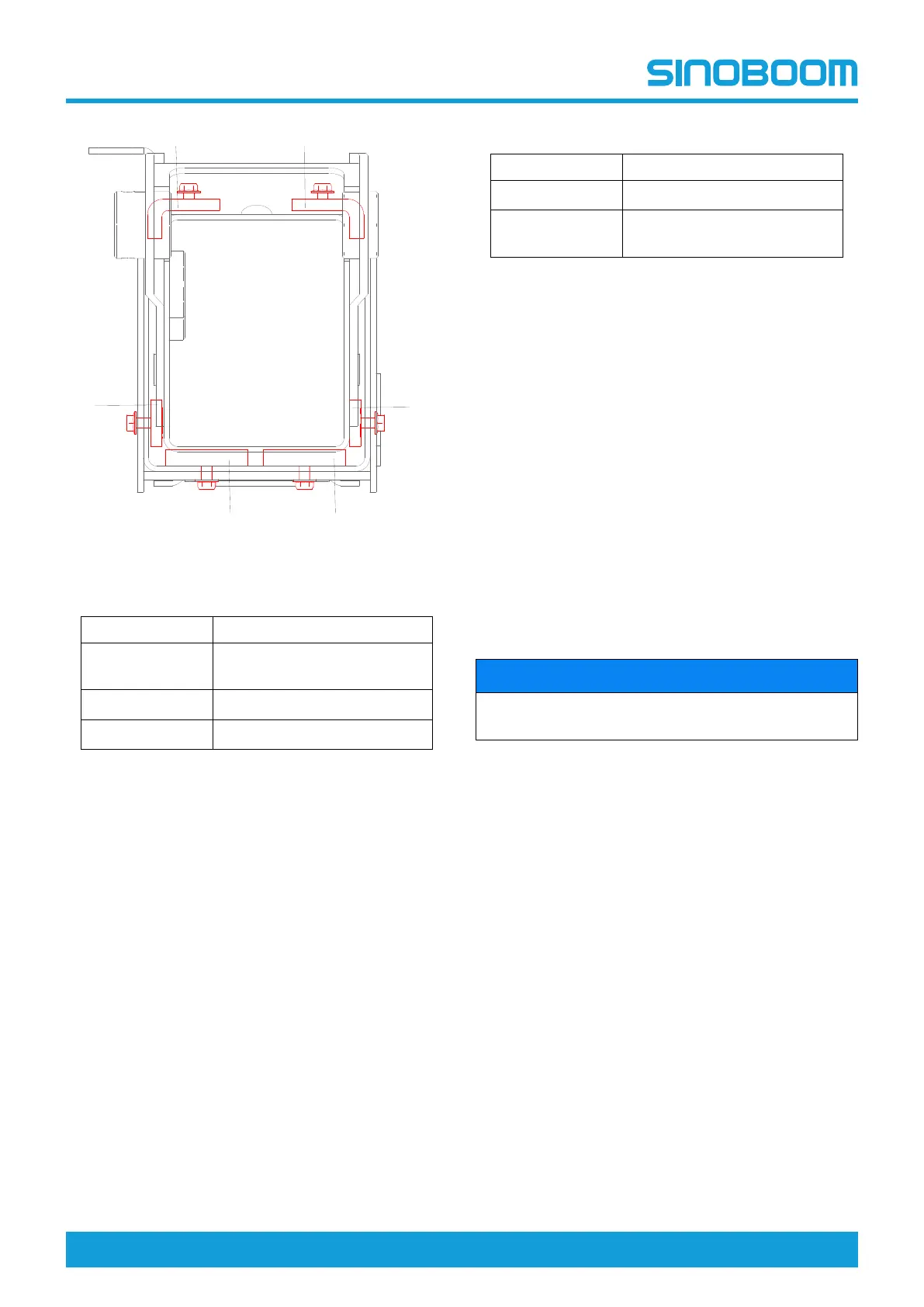

Fig 9 Diagram of sliders at boom tail

Table 6-3 Boom slider thickness

No. Slider thickness

1

11mm (0.43in)/

14mm (0.55in)

2

11mm (0.43in)

3

16mm (0.63in)

Table 6-3 Boom slider thickness(Continued)

No.

Slider thickness

4

11mm (0.43in)

Telescopic

cylinder slider

17mm (0.67in)

The boom slider is essential for the safe operation of the

machine. As a friction pair will develop between each

slider and the telescopic boom surface, improper slider

gaskets or continued use of extremely worn sliders may

result in component damage and unsafe operation. It is

recommended to check the boom slider thickness once

a year or after 1000 hours of operation.

1. Remove the cover plate from the head of the main

boom (near the turntable) or the nylon brush at the

tail of the main boom (near the platform).

2. Measure the thickness of each slider at the head

and tail of the main boom.

3. If the telescopic cylinder has sliders, measure the

slider thickness after the telescopic cylinder is

removed.

4. Compare the measured thickness value of each

slider with the value specified in the above table,

and replace the slider assembly in time if the wear

extent of the slider is greater than or equal to 3mm

(0.118in).

NOTICE

The disassembled slider cannot be reused and must

be replaced with a new slider assembly.

Loading...

Loading...