© March 2023

58

AB16EJ Plus Operation Manual

MAINTENANCE

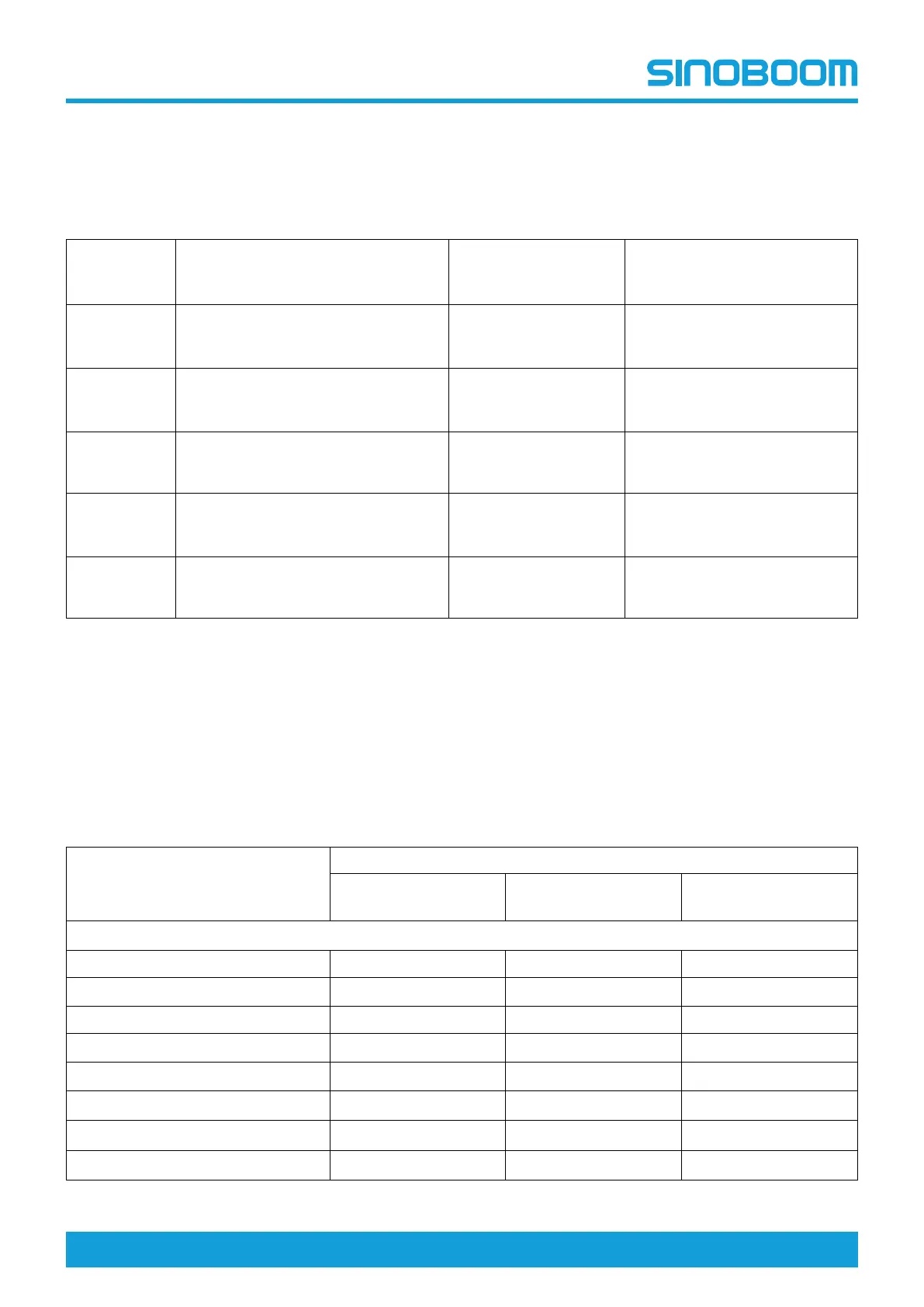

Responsible Persons and Qualifica-

tions for Performing Inspection and

Maintenance

Table 10-5

Inspection

Type

Inspection Frequency

Primary

Responsible

Persons

Service Qualifications

Pre-operation

Inspection

Before starting/restarting work,

change of user, after each

maintenance activity.

User or operator

Properly trained user or

operator

Pre-delivery

Inspection

(PDI)

Before each sale, lease or rental

delivery

Owner, dealer or user

Qualified Sinoboom technician

Regular

Inspections

In service for 3 months or 250 hours

(whichever comes first) or out of

service for more than 3 months

Owner, dealer or user

Qualified Sinoboom technician

Annual

Machine

Inspection

Once a year and no later than 13

months from the date of the previous

annual inspection

Owner, dealer or user

Factory-trained service

technician

Preventive

Maintenance

At intervals specified in the Inspec-

tion and Preventive Maintenance

Schedule

Owner, dealer or user

Qualified Sinoboom technician

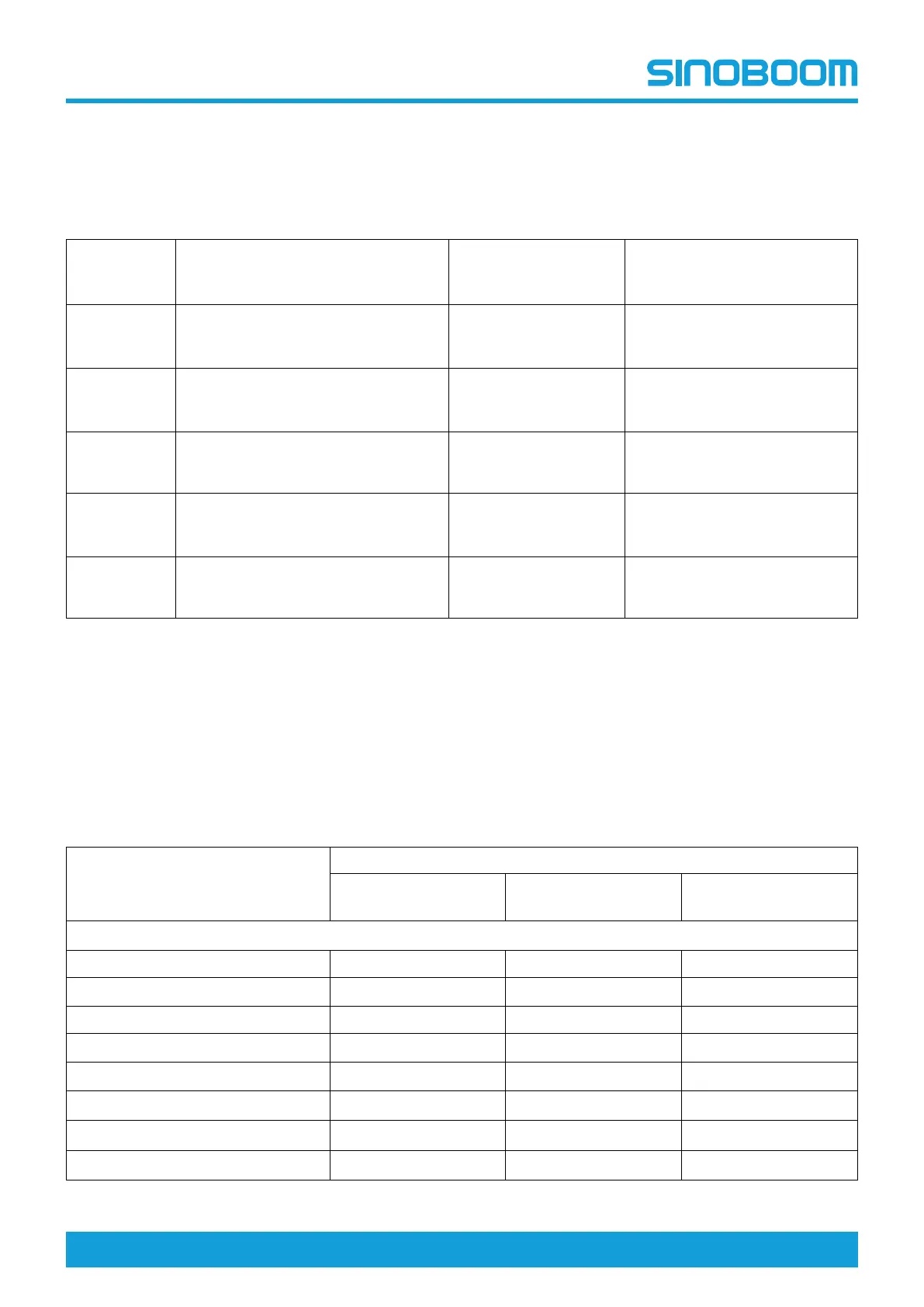

Inspection and Preventive Maintenance

Schedule

Perform inspection and preventive maintenance for the

items in the table below at the specified intervals. Main-

tenance and inspection intervals are calculated based

on the months of service or the “cumulated operating

hours” displayed on the ground controls (whichever

comes first).

Inspection intervals are based on the use of the ma-

chine under normal operating conditions. The intervals

should be shortened accordingly when operating in

harsh environmental conditions.

Table 10-6 Inspection and Preventive Maintenance Schedule

Items

Intervals

Before each

delivery

1

or quarterly

2

Semiannually

3

Annually

4

Chassis assembly

Chassis 2 2 2

Tires

1, 2 1, 2 1, 2

Wheel nuts 1

50

1

50

1

50

Travel motor

1, 2 1, 2 1, 2

Travel reducer

1, 2, 6 1, 2, 6 1, 2, 6, 11

Steering components

1, 2 1, 2 1, 2

Axles \ Extending axles(if equipped)

1, 2, 3 1, 2, 3 1, 2, 3

Bearings

1, 2, 5, 12 1, 2, 5, 12 1, 2, 5, 12

Loading...

Loading...