© Feb. 2023

40 TB20J Plus Maintenance Manual

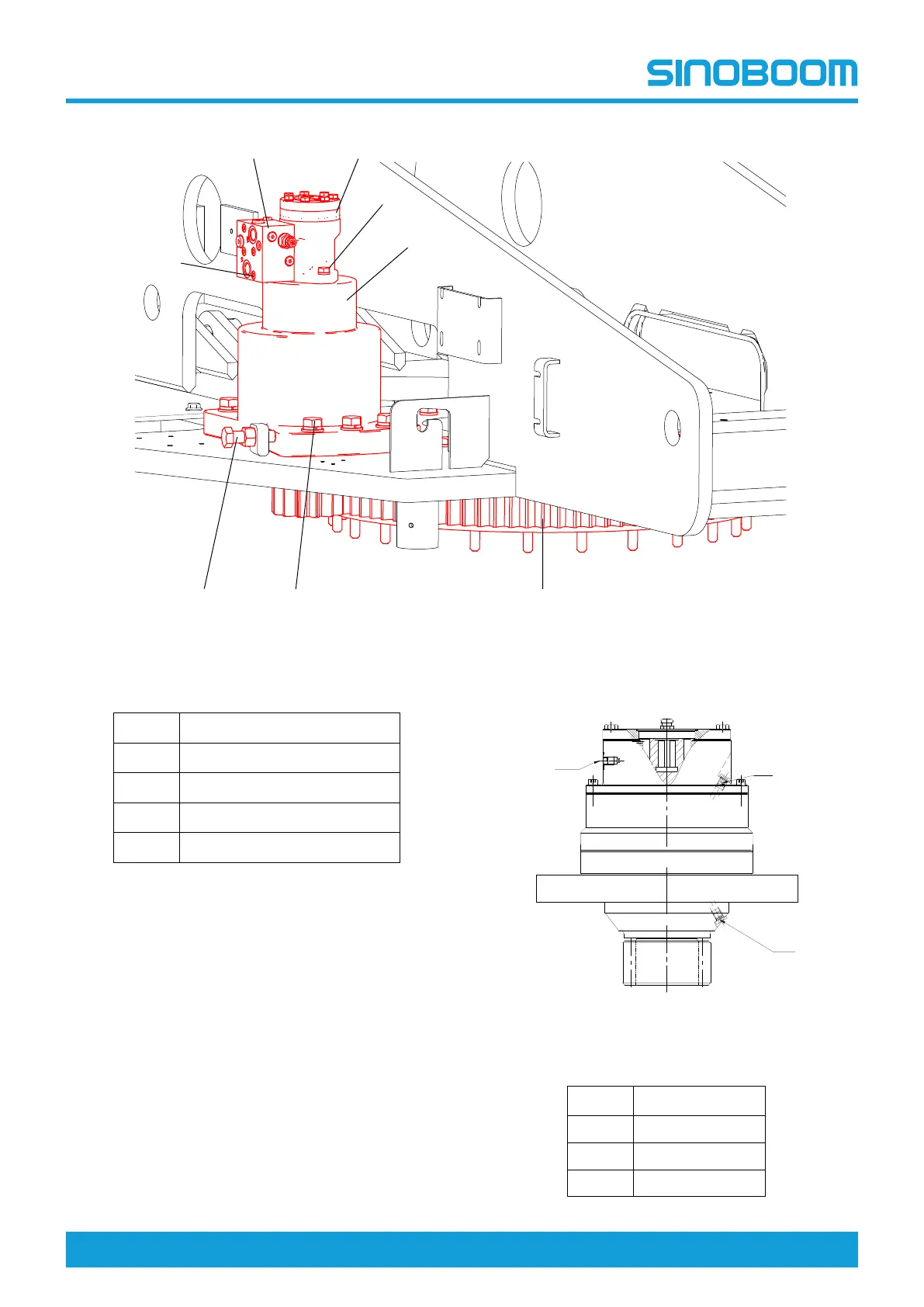

CHASSIS AND TURNTABLE ASSEMBLY

Fig 7 Diagram of slewing mechanism

Table 5-3 Slewing mechanism

No.

Description

A

Slewing cushion valve

B

Slewing motor

C

Slewing reducer

D

Slewing bearing

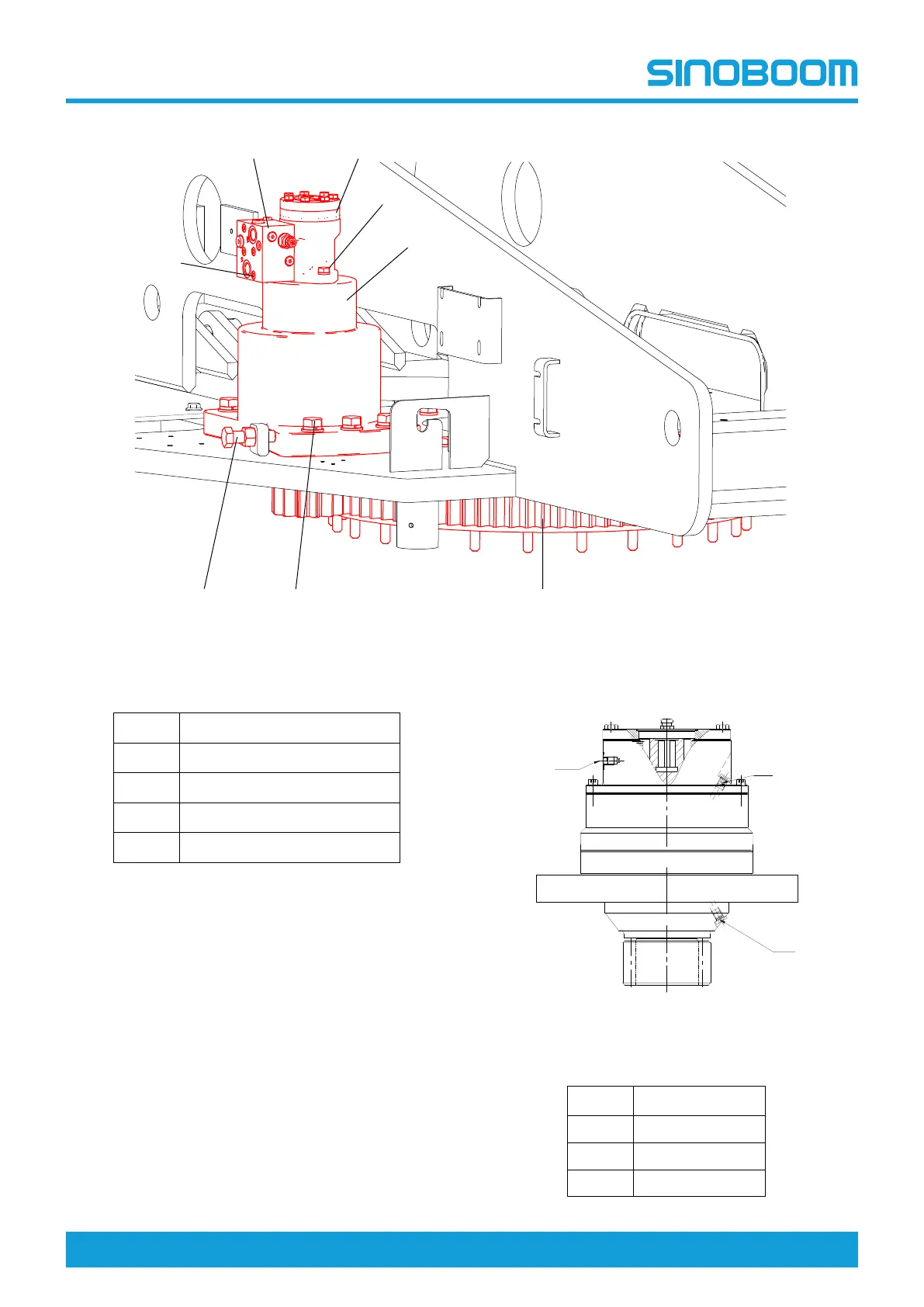

Check Oil Level in Slewing Reducer

The slewing reducer with inappropriate gear oil level will

lead to reduced machine performance and even compo-

nent damage. It’s recommended to check the oil level in

slewing reducer every 3 months or after 250 working

hours.

1. Open the left turntable cover to locate the slewing

reducer.

2. Remove the oil filler plug from the reducer, and

check the oil level, which should be even with the oil

port.

3. Remove the oil inlet plug from the brake, and check

the oil level, which should be even with the oil port.

4. Add oil as needed, until the oil level is even with the

oil port.

Fig 8 Position of slewing reducer oil ports

Table 5-4 Description of slewing reducer oil ports

No.

Description

1 Brake oil inlet

2 Oil filler

3 Oil outlet

Loading...

Loading...