CHASSIS AND TURNTABLE ASSEMBLY

TB20J Plus Maintenance Manual 41

© Feb. 2023

Replace Gear Oil in Slewing Reducer

Regularly replacing the gear oil in slewing reducer is vi-

tal to maintaining machine performance and extending

service life of the machine. It’s recommended to replace

the gear oil in slewing reducer every year or after 1000

working hours.

Drain waste oil:

1. Open the left turntable cover to locate the slewing

reducer.

2. Place a suitable vessel under the oil outlet of the

slewing reducer.

3. Remove the oil outlet plug to drain the gear oil in the

reducer to the vessel.

4. Install the oil outlet plug.

Fill with clean oil:

1. Remove the oil filler plug from the reducer, add new

industrial gear oil with the viscosity grade of 75W-90

to the oil filler until the oil level is even with the oil

port, and install the oil filler plug.

2. Remove the oil filler plug from the brake, add new

industrial gear oil with the viscosity grade of 75W-90

to the oil filler until the oil level is even with the oil

port, and install the oil filler plug.

3. Clean up the gear oil spills during the process.

Lubricate Slewing Bearing

Regular lubrication of slewing bearing is essential to

maintain machine uptime and extend service life. Failure

to lubricate the slewing bearing regularly may lead to

abnormal operation of the machine and accelerated

component damage. It is recommended to lubricate the

slewing bearing every 3 months or 250 hours of opera-

tion, and when the machine is operated in multiple shifts

or exposed to harsh environments, the lubrication fre-

quency and amount of lubricant should be increased

accordingly.

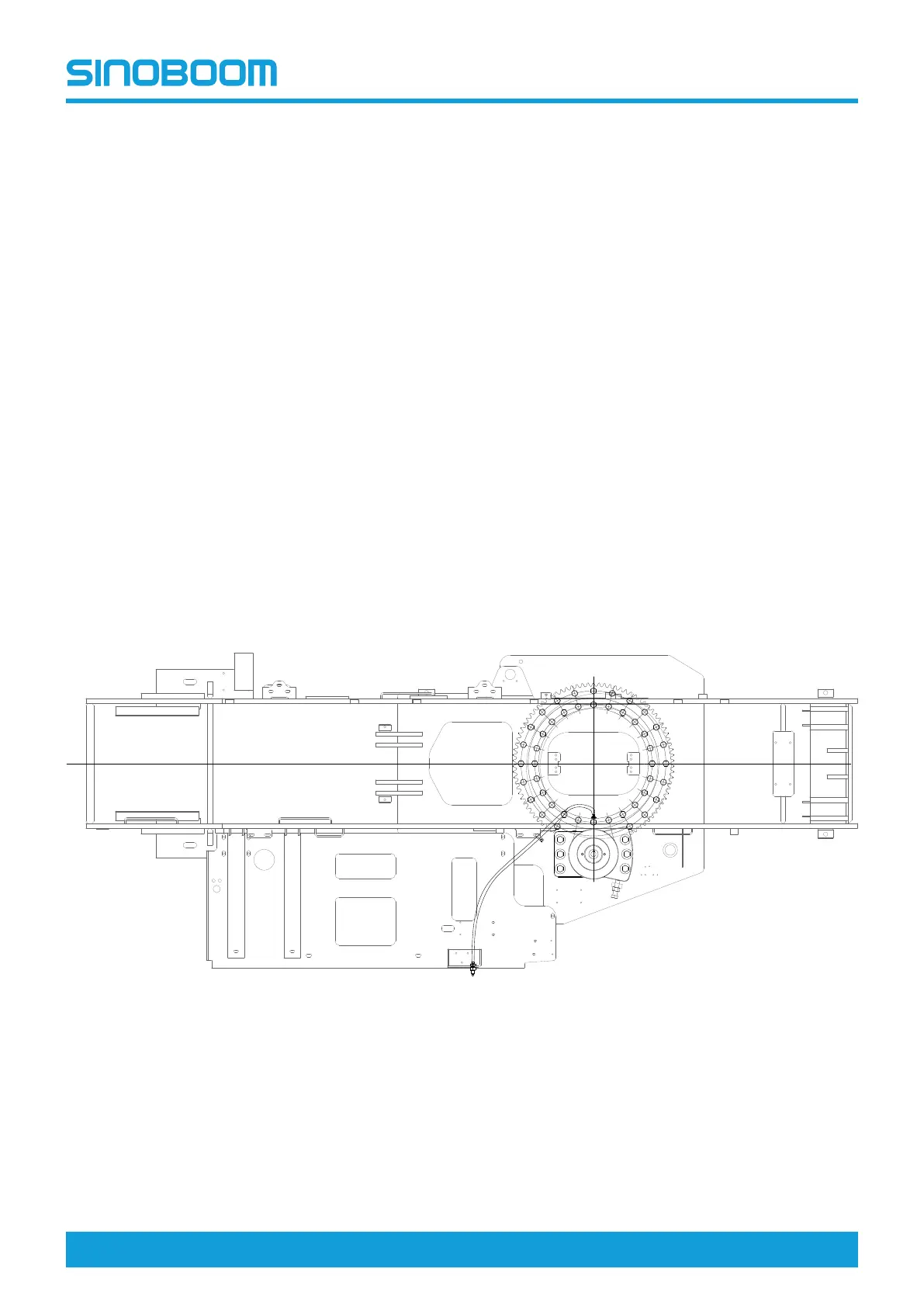

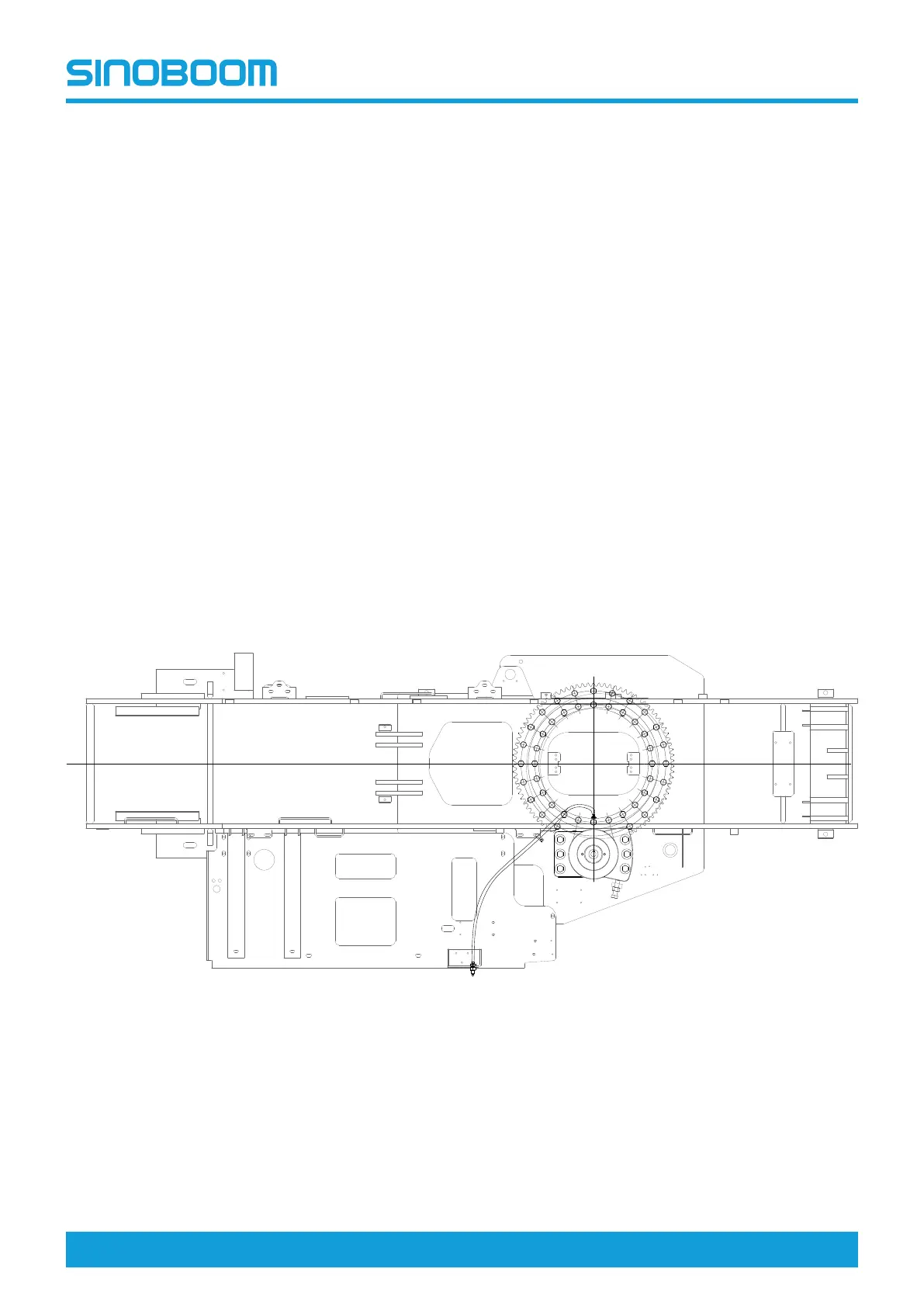

1. As shown in the figure below, connect the slewing

bearing and the grease nipple with a hose.

2. Position the oil gun nozzle on the grease nipple and

fill with ZL-3 lithium-based grease which will be

transported to the turntable slewing bearing through

the hose.

3. Then, rotate the turntable by 100-130mm (4-5in)

each time until the whole slewing bearing is fully

lubricated.

4. Apply lubricating grease on the outer gear of the

slewing bearing and the gear on the slewing reducer

evenly with a brush.

5. Remove excess grease.

Fig 9 Diagram of lubricating slewing bearing remotely

Inspect Slewing Bearing Bolts

It is recommended to check the slewing bearing bolts

after the first 50 hours of operation, and every 3 months

or 250 hours of operation thereafter.

If any bolt is found to be missing or slack, replace it with

a new bolt, apply Loctite 272 threadlocking adhesive to

the bolt thread and tighten the bolt with the torque speci-

fied in the Torque Specifications section. After replac-

ing and tightening the slewing bearing bolt, re-inspect

the bolt for tightness.

Loading...

Loading...