© Feb. 2023

46 TB20J Plus Maintenance Manual

CHASSIS AND TURNTABLE ASSEMBLY

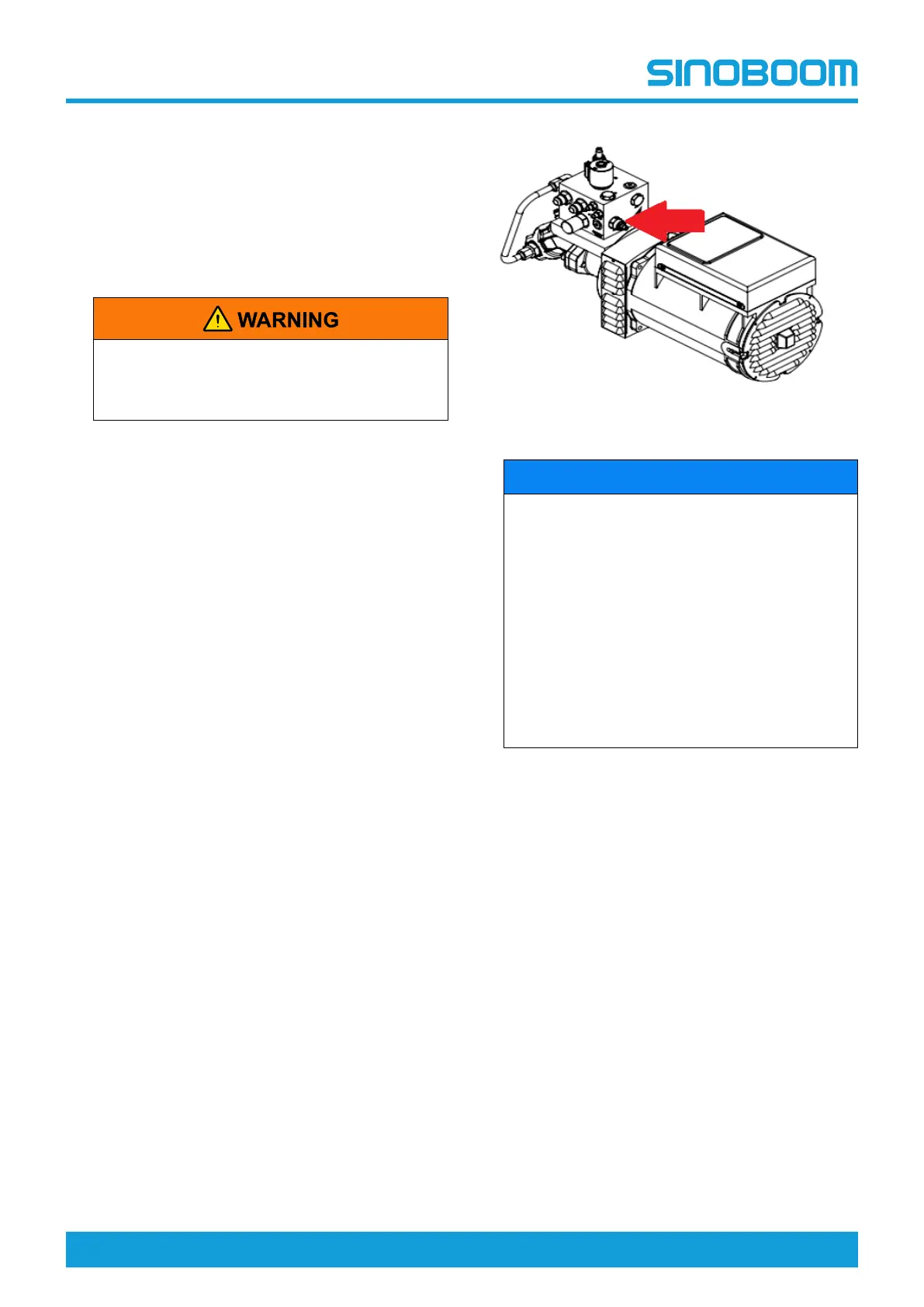

2. Install the mounting plate #1 of the hydraulic gener-

ator and secure it with bolt #2 and nut #3.

3. Use suitable lifting equipment to lift the hydraulic

generator #4 above the turntable counterweight,

and adjust the orientation (refer to the placement

position in the dotted box A in the figure above) so

that the hydraulic generator can enter the turntable

structure smoothly.

Always check the position of the hydraulic

generator during the installation process to

ensure that the hydraulic generator does not

interfere with other parts of the machine.

4. Then, rotate the hydraulic generator 90° to adjust its

direction (refer to the position C in the figure above).

5. Align the mounting holes of hydraulic generator with

the mounting holes in the mounting plate #1.

6. Install and secure the hydraulic generator with bolt

#5 and nut #6.

Debugging

After the hydraulic generator is installed, the machine

needs to be debugged as follows:

1. Start the engine, and after the engine operates sta-

bly, move the hydraulic generator switch to warm up

the hydraulic system until the oil temperature ex-

ceeds 45°C (113°F).

2. Measure whether the output voltage of the genera-

tor meets the requirements of use. If the output volt-

age is less than the required voltage, the motor runs

too slow; if the output voltage is too high, the motor

runs too fast.

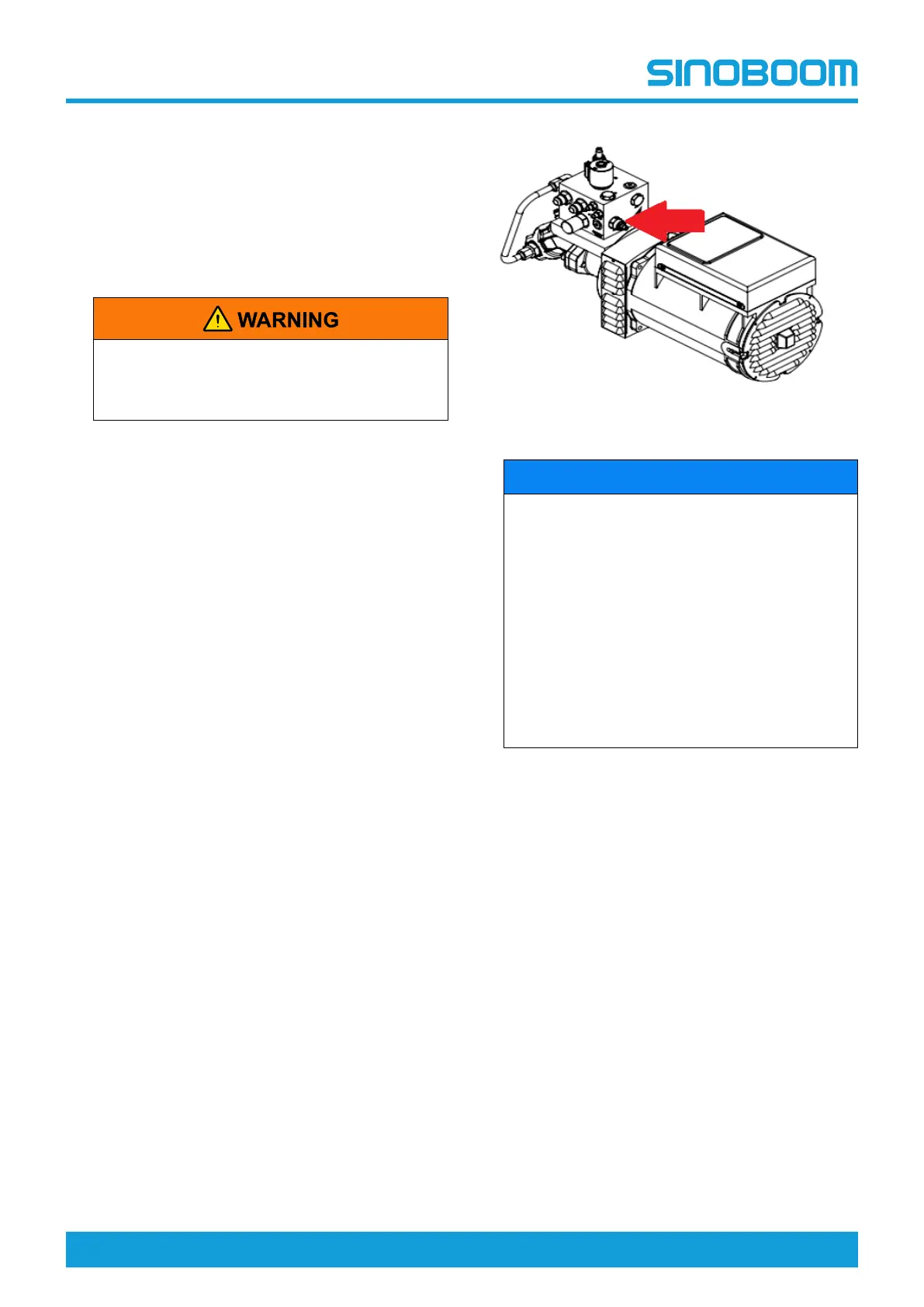

3. The speed of the motor depends on the input flow

rate, so the output voltage can be used to determine

whether the motor flow rate is appropriate. The posi-

tion of the flow valve is shown by the arrow in the

figure below. Adjust the valve clockwise to decrease

the flow rate, or counterclockwise to increase the

flow rate. Adjust the flow valve based on the output

voltage until the output voltage meets the require-

ments of use in your region.

Fig 16 Diagram of flow valve

NOTICE

If the flow valve is fully opened, but the voltage

still can not meet the requirements of use, the

reason may be that:

• The hydraulic system does not warm up suffi-

ciently, so the oil temperature has not reached

the required temperature. Wait for the oil tem-

perature to rise above 45°C (113°F), then de-

termine the output flow based on the actual

output voltage, and adjust the flow valve until

the voltage reaches the requirements of use;

• The pump LS set pressure is too low, resulting

in insufficient output flow of the pump, so the

LS set pressure needs to be increased.

4. After the voltage is adjusted, run the machine with

or without load for about 30min. If the motor makes

a buzzing sound or the pump outlet hose vibrates at

certain frequency, the pump LS set pressure value

is not suitable and needs to be decreased. Turn the

screw in the figure below clockwise to increase the

LS set pressure value, or counterclockwise to de-

crease the LS set pressure value.

Loading...

Loading...