© Feb. 2023

44 TB20J Plus Maintenance Manual

CHASSIS AND TURNTABLE ASSEMBLY

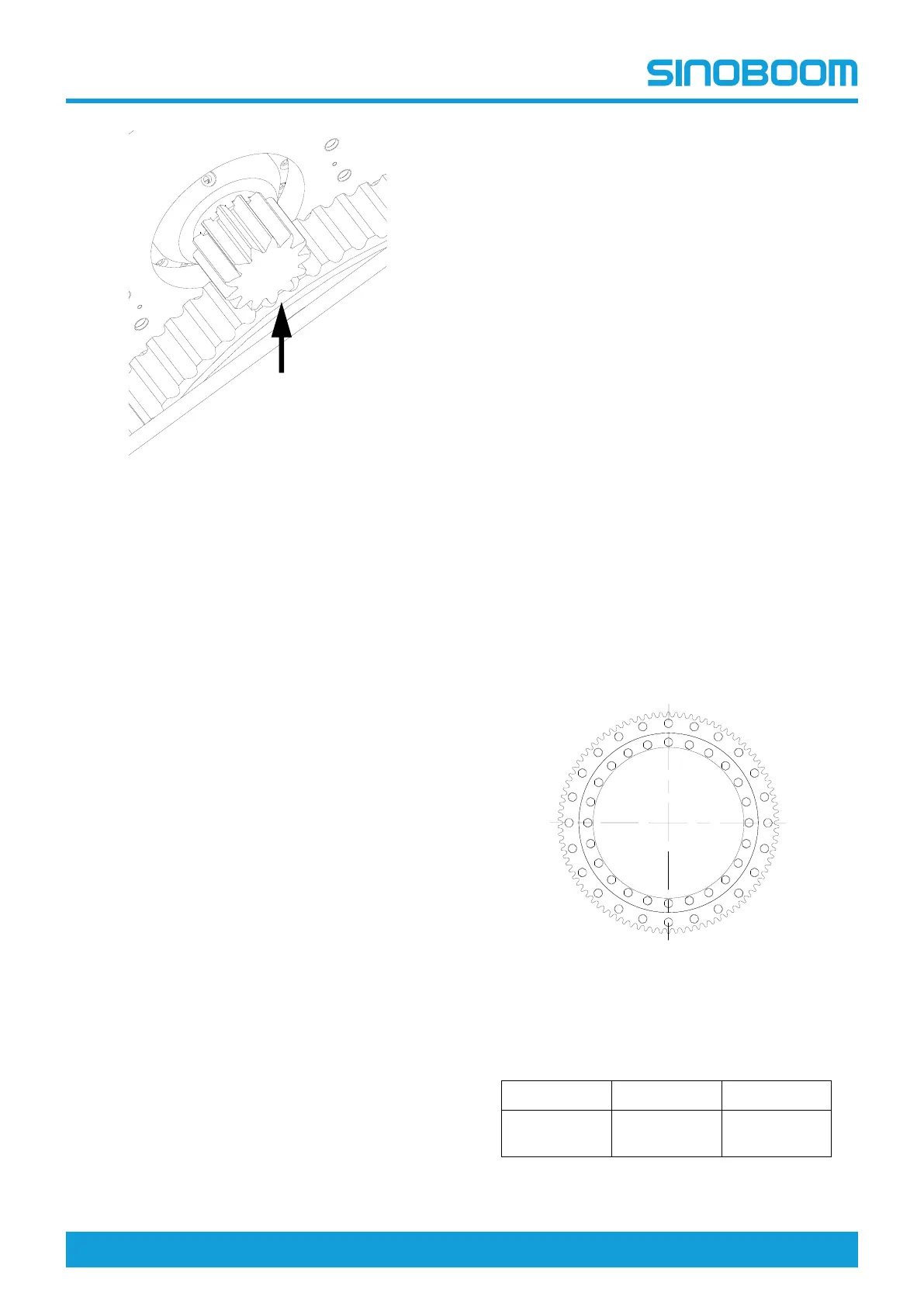

Fig 13 Gear backlash

4. If the measured gear backlash exceeds the speci-

fied value, adjust the gear backlash to the specified

value with the adjusting bolt and locking nut at posi-

tion #4, and the specific method is described in Ad-

just Slewing Mechanism Gear Backlash .

5. Apply Loctite 272 threadlocking adhesive to the

bolts with washers fitted, install the bolts at position

#3 one by one to secure the slewing reducer and

the turntable, and then pre-tighten the bolts

diagonally.

6. Ensure that the slewing reducer fits perfectly to the

turntable mounting surface.

7. Tighten the bolts diagonally with a wrench.

8. Fill the slewing reducer with gear oil to cover the

gear surface.

9. Clean the mounting surface of the slewing reducer,

and match the slewing motor pivot pin with the re-

ducer pin hole.

10. Turn the motor housing so that the bolt hole on the

slewing motor is aligned with that on the reducer.

Apply Loctite 272 threadlocking adhesive to the

bolts with washers fitted, install and tighten the bolts

at position #2 according to the specified torque.

11. Match the bolt hole on the slewing cushion valve

with the mounting hole on the slewing motor, apply

Loctite 272 threadlocking adhesive to the bolts with

washers fitted, install and tighten the bolts at posi-

tion #1 according to the specified torque (refer to

the Torque Specifications ).

Install slewing bearing

1. Use suitable lifting equipment to lift the slewing

bearing to the chassis mounting surface.

2. Check the clearance between the slewing bearing

mounting surface and the chassis mounting surface

with a feeler gauge, ensuring the clearance ≤

0.2mm (0.008in).

3. Using the special high-strength washers for high-

strength bolts, fit the washer face with the mounting

surface, and apply Loctite 272 threadlocking adhe-

sive, and then install the bolts to the outer ring of the

slewing bearing.

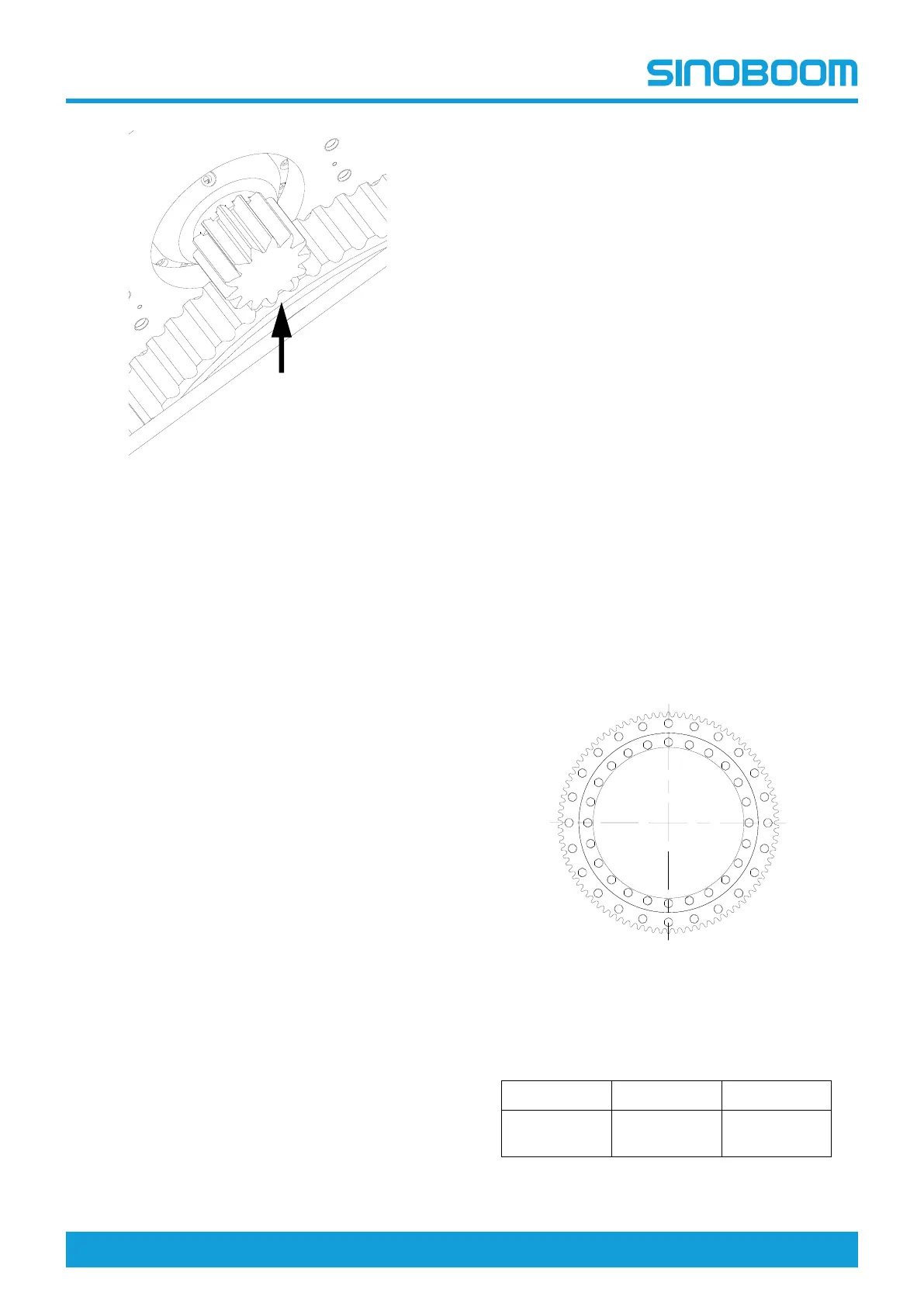

4. Then tighten the bolts in the sequence shown in the

following diagram and follow the steps in the table

below.

5. Rotate the inner ring of the slewing bearing by hand

to ensure smooth movement.

6. Remove the lifting equipment from the slewing

bearing.

7. Rotate the inner ring of slewing bearing so that the

soft belt area on the inner ring and that on the outer

ring are symmetrically distributed with the slewing

bearing as the center.

8. Use suitable lifting equipment to lift the turntable to

the slewing bearing mounting surface.

9. Using the special high-strength washers for high-

strength bolts, fit the washer face with the mounting

surface, and apply Loctite 272 threadlocking adhe-

sive, and then install the bolts to the inner ring of the

slewing bearing.

10. Then tighten the bolts in the sequence shown in the

following diagram and follow the steps in the table

below.

Fig 14 Tightening sequence of slewing bearing

bolts

Table 5-5 Table of slewing bearing bolt tightening

torques

First step

Second step

Third step

160Nm

(118ft-lb)

270 Nm

(199ft-lb)

300Nm

(221ft-lb)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Loading...

Loading...