18

SJ30AJE, SJ30ARJE196274AF

Section 1 – Scheduled Maintenance Scheduled Maintenance Inspections

1.6 Scheduled Maintenance

Inspections

Begin the scheduled maintenance inspections by

checking each item in sequence for the conditions listed

in this section.

WARNING

To avoid injury, do not operate a MEWP until all

malfunctions have been corrected.

WARNING

To avoid possible injury, ensure the MEWP power

is off during your visual and daily maintenance

inspections.

CAUTION

Ensure the MEWP is on a firm, level surface.

NOTE

While performing visual and daily inspections

in different areas, be sure to also inspect limit

switches, electrica,l and hydraulic components.

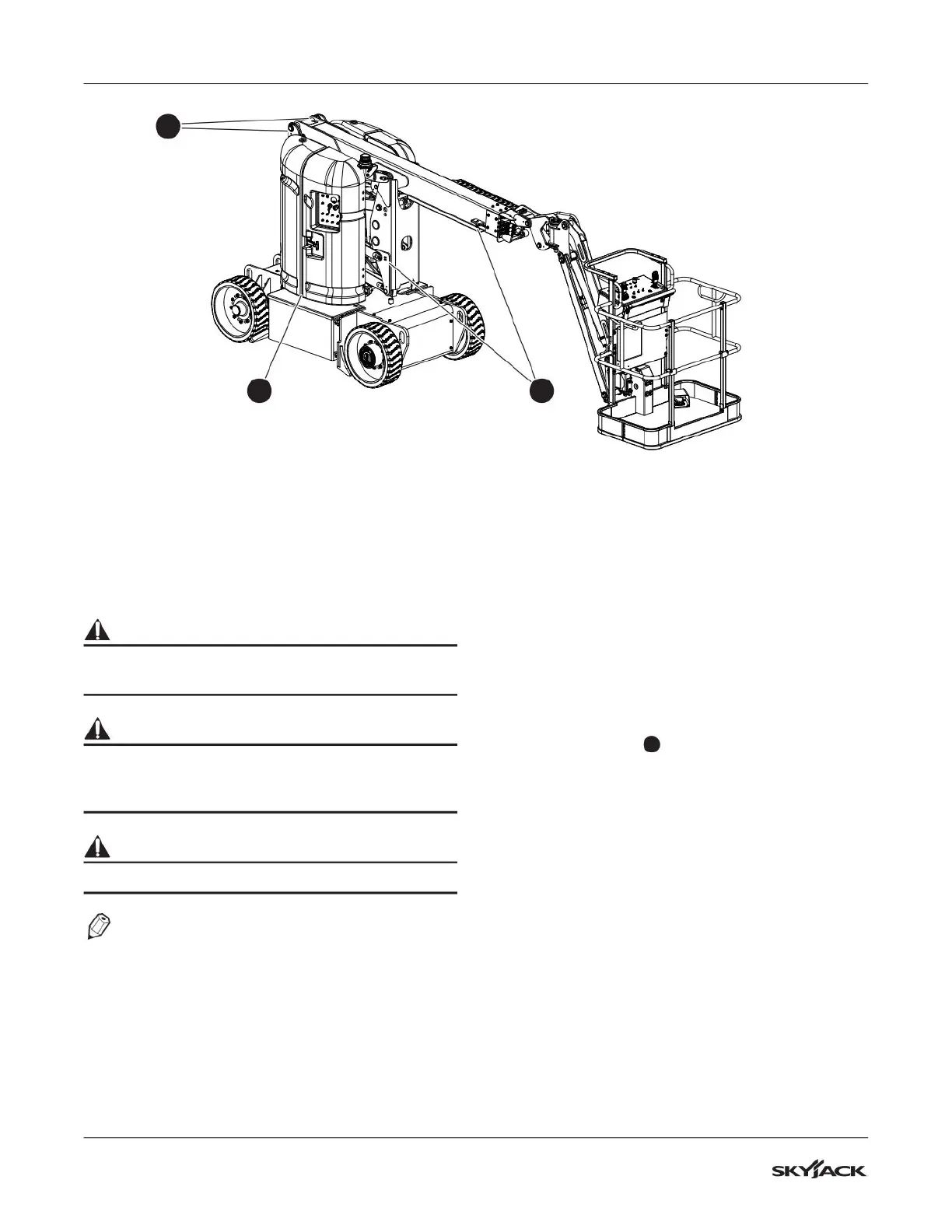

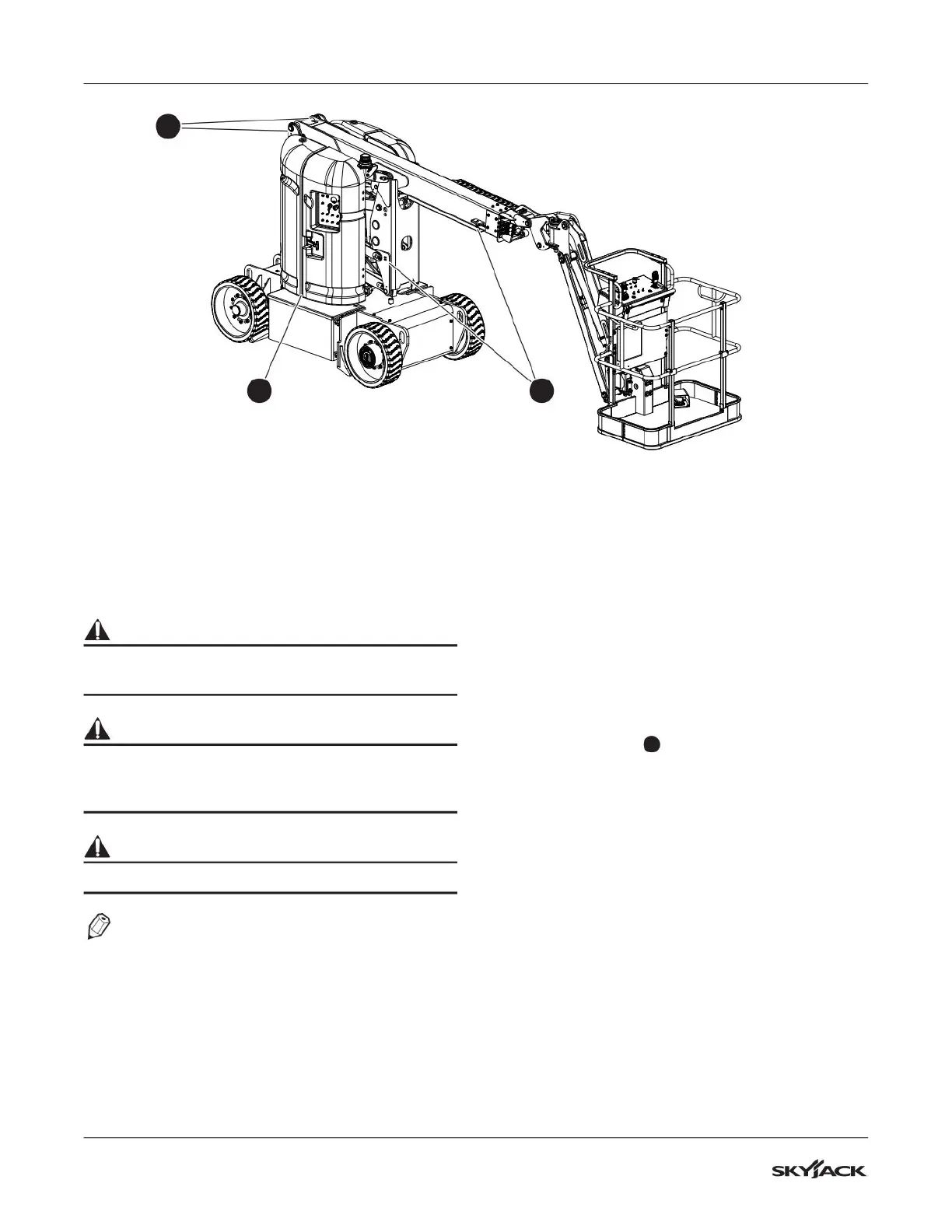

1.6-1 Labels (B)

Refer to the labels section in the operating manual

and ensure all labels are in place and are legible.

1.6-2 Electrical

Maintaining the electrical components is essential to

the good performance and service life of the MEWP.

Inspect the following areas for chafed, corroded, and

loose wires:

▪

boom to platform cable harness

▪

engine compartment electrical panel

▪

engine wiring harness

▪

rotary manifold wiring

1.6-3 Limit Switches (B)

Ensure limit switches

1

are properly secured with

no signs of visible damage, and movement is not

obstructed.

1.6-4 Hydraulic

Maintaining the hydraulic components is essential to

the good performance and service life of the MEWP.

Perform a visual inspection around the following

areas:

▪

hydraulic tank filter, fittings, hoses, emergency

power unit and turret/base surface

▪

engine compartment fittings, hoses, main pump,

filter and turret/base surface

▪

all hydraulic cylinders

▪

all hydraulic manifolds

▪

the underside of the turret

▪

the underside of the base

▪

the ground area under the MEWP

Limit Switch Locations

1 1

1

Loading...

Loading...