20

SJ30AJE, SJ30ARJE196274AF

Section 1 – Scheduled Maintenance Scheduled Maintenance Inspections

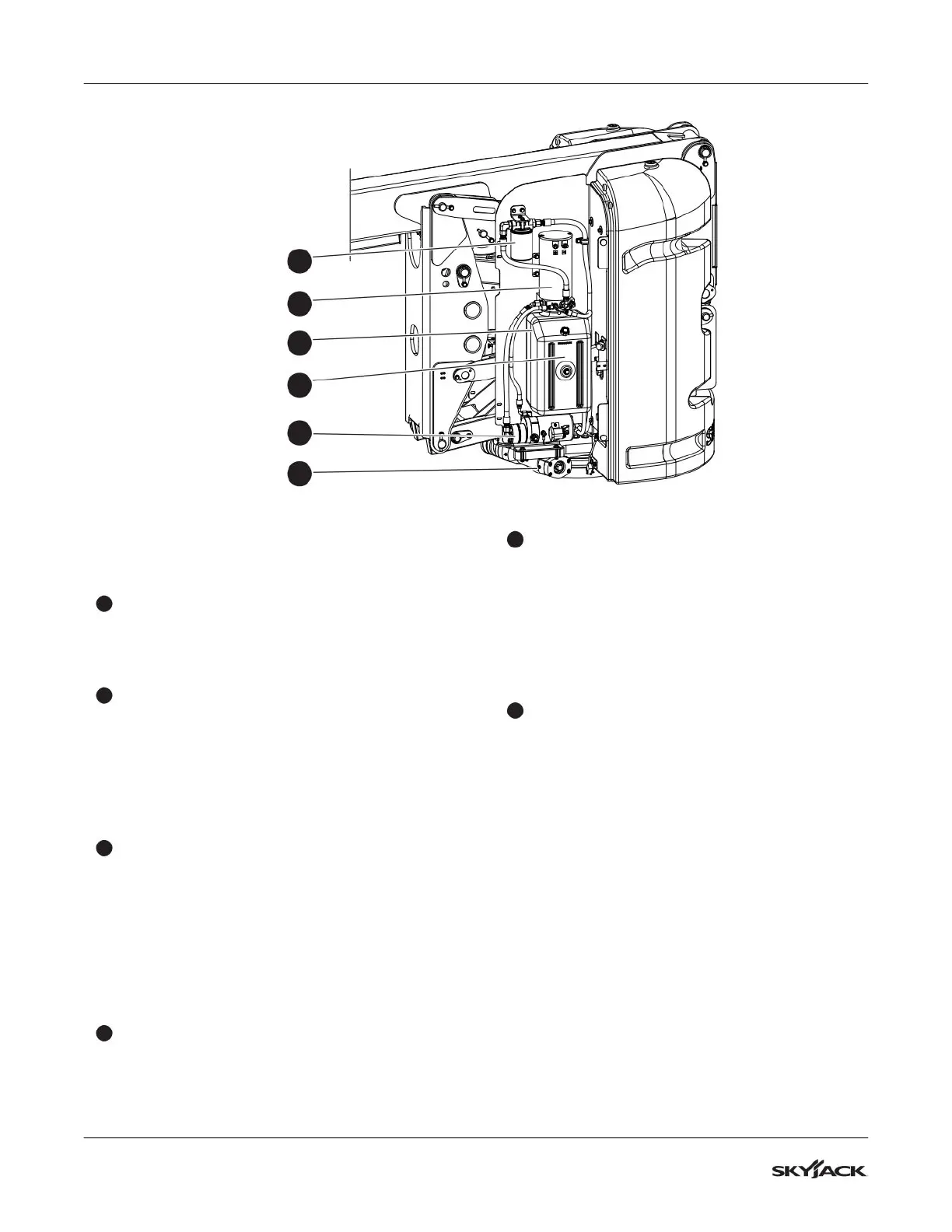

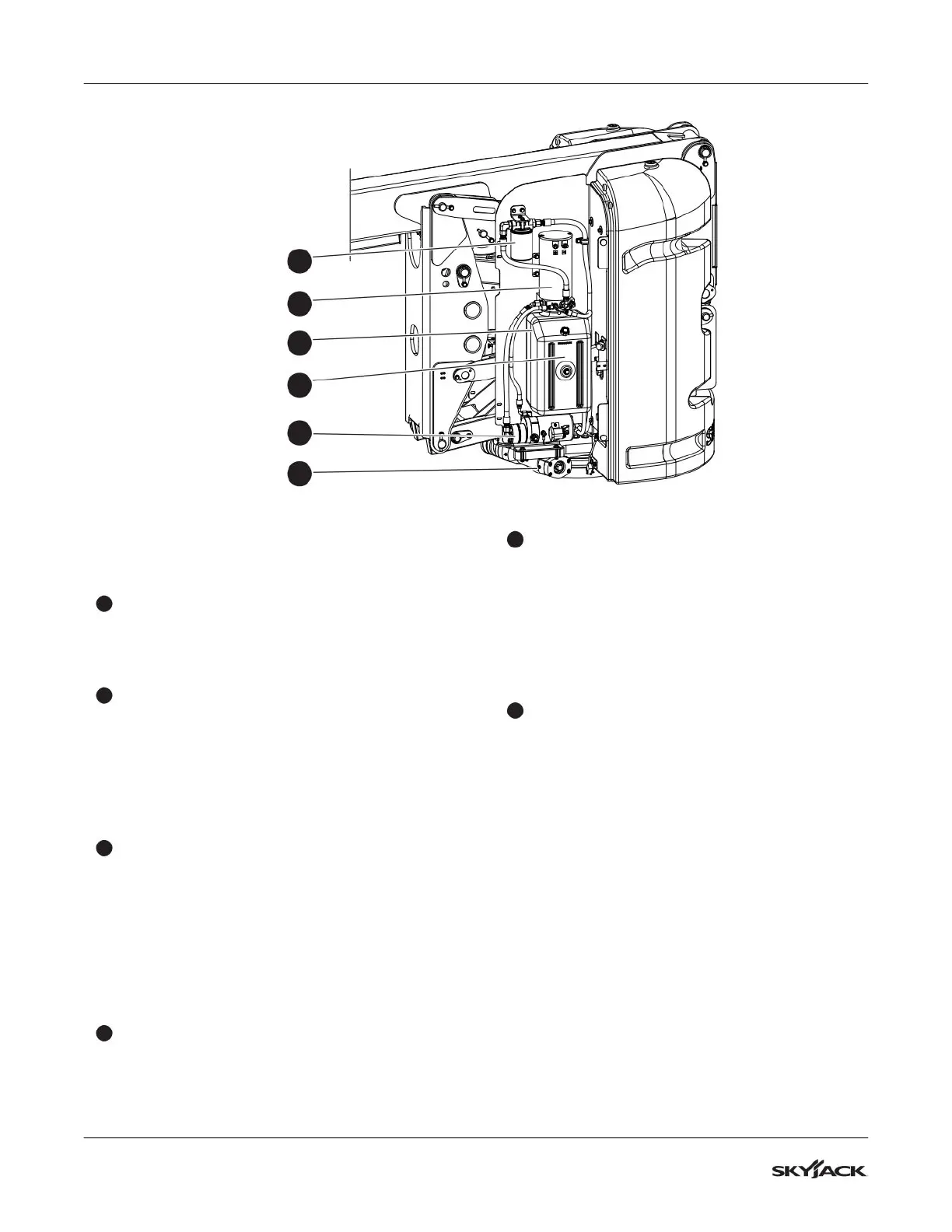

1.6-6 Motor/Hydraulic Compartment

▪

Ensure all compartment latches are secure and

in proper working order.

1

Hydraulic Tank (B)

▪

Ensure the hydraulic filler cap is secure.

▪

Ensure the tank shows no visible damage and

no evidence of hydraulic leakage.

2

Hydraulic Pump/Motor (B)

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure all bolts are properly tightened.

▪

Ensure all fittings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

3

Hydraulic Oil (B)

▪

Ensure the boom is in the stowed position, and

then visually inspect the sight gauge located on

the side of the hydraulic oil tank.

▪

Ensure the hydraulic oil level is within the

minimum and maximum range found on the

hydraulic oil level indicator label. Add oil as

needed. Refer to 2.9 Hydraulic Specifications for

recommended oil type.

4

Hydraulic Filter (B)

▪

Ensure the housing is secure and shows no

visible damage or leakage.

5

Emergency Power Unit (B)

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure there are no loose wires or missing

fasteners.

▪

Ensure all fittings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

6

Turret Rotation Motor/Gear (B,C)

▪

Ensure there are no loose or missing parts and

there is no visible damage.

▪

Ensure all bolts are properly tightened.

▪

Ensure all fittings and hoses are properly

tightened and there is no evidence of hydraulic

leakage.

C - Annual Inspection

▪

For the lubrication procedure refer to section 2.6

Tire Specifications.

1

2

3

4

5

6

Loading...

Loading...