HRX-OM-Q026

Chapter 8 Documents

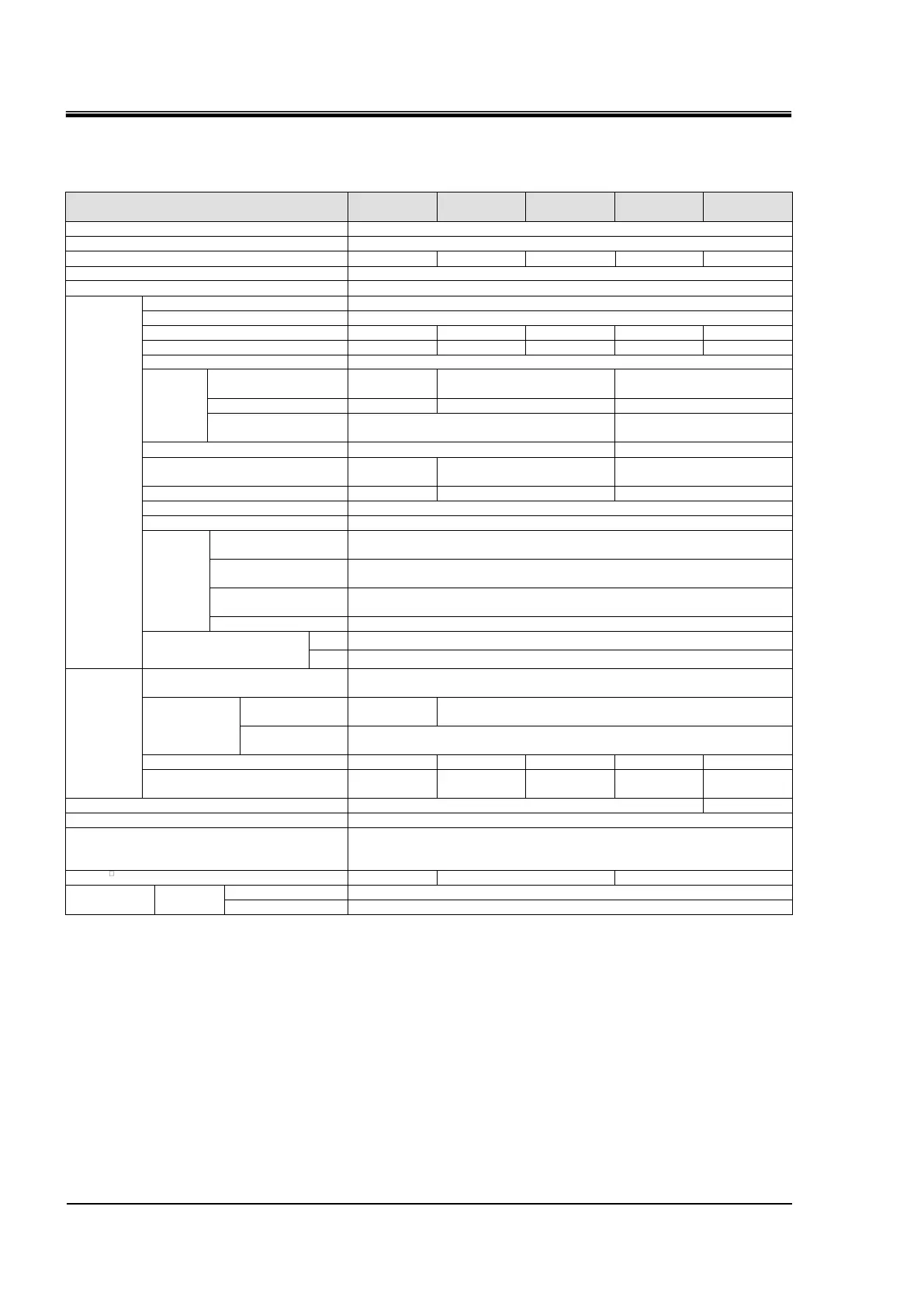

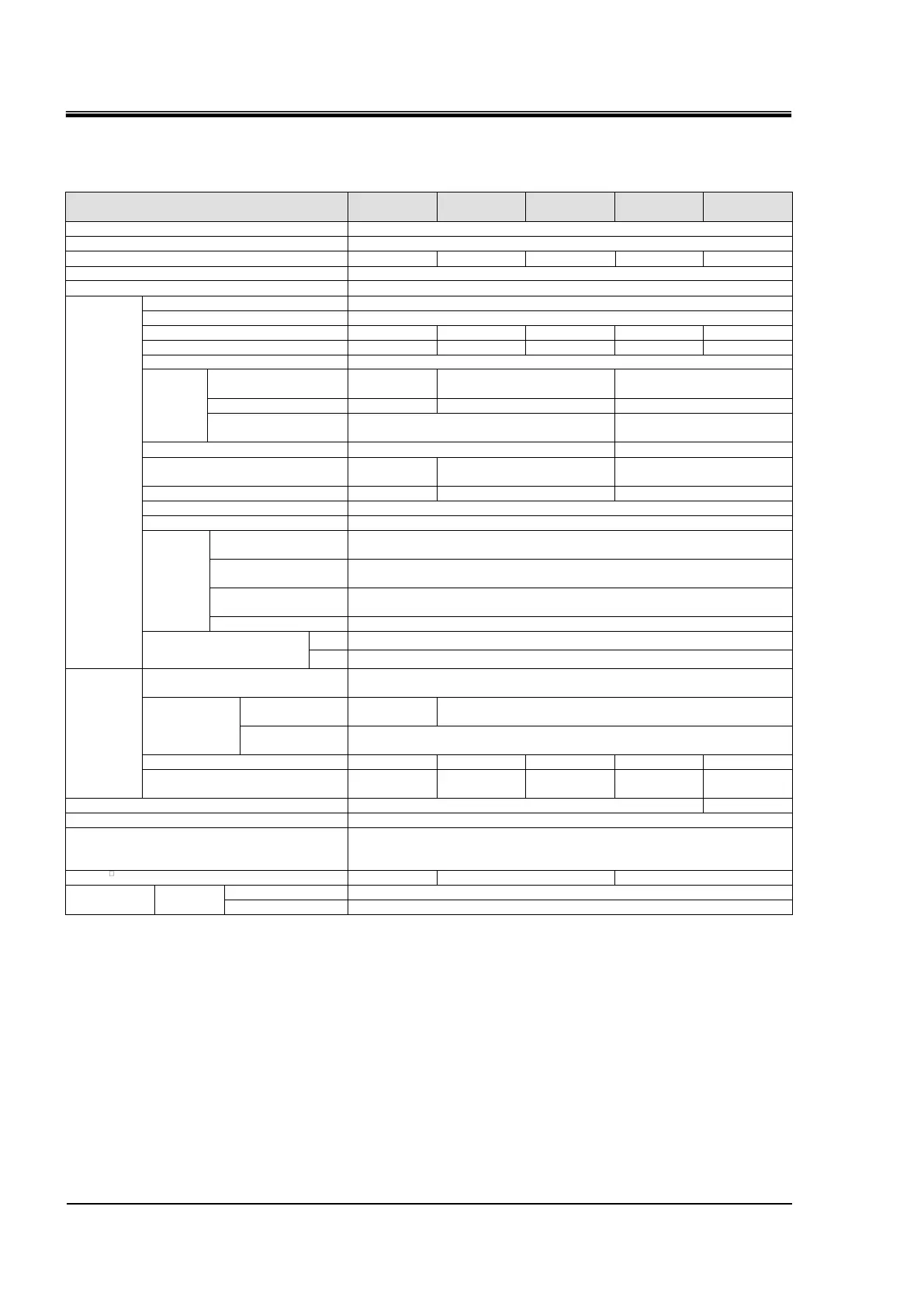

8.1 Specifications HRSH Series

8-2

8.1.2 HRSH100/150/200/250/300-A-40-

Table 8-2 Specifications of HRSH100/150/200/250/300-A-40-

Clear water, 15 to 40% ethylene glycol aqueous solution, DI water (pure water)

Settable pressure range

6

Minimum necessary flow

rate

7

Rc1 (Symbol F: G1, Symbol N: NPT1)

Rc3/4 (Symbol F: G3/4, Symbol N: NPT3/4)

Automatic

water fill

function

(Standard

)

Supply side

pressure range

Supply side

water temp. range

Automatic water fill port

size

Rc1/2 (Symbol F: G1/2, Symbol N: NPT1/2)

Rc1 (Symbol F: G1, Symbol N: NPT1)

Fluid contact part material

Stainless steel, Copper (Brazing filler metal for the heat exchanger), Bronze, Brass,

PTFE, PU, FKM, EPDM, PVC, NBR, POM, PE, NR

3 phase 380 to 415 VAC (50/60Hz)

Allowable voltage fluctuation ±10% (No continuous voltage fluctuation)

Applicable earth

leakage

breaker

(Standard)

Rated operating current

5

Rated power

consumption

5

Noise level (Front: 1m, height: 1m)

5

Water-proof specification

Alarm code list label 2 pcs. (English 1, Japanese 1), Operation manual (for

installation/operation) (English 1, Japanese 1),Y-strainer (40 mesh) 25A, Barrel nipple 25A,

Anchor bracket 2pcs. (including 6 pcs. of M8 bolts)

8

Weight (in the dry state)

1: When the ambient temperature or circulating fluid temperature is 10

o

C or below, refer to "3.2.2 Operation at low ambient temperature or low

circulating fluid temperature".

2: Use fluid for circulating fluid that conforms to:

Clean water: Water Quality Standards of the Japan Refrigeration and Air Conditioning Industry Association (JRA GL-02-1994)

15 to 40% ethylene glycol aqueous solution: Diluted with clean water, without any additives such as antiseptics. (Refer to "3.2.2 Operation at low

ambient temperature or low circulating fluid temperature" for the concentration of the ethylene glycol aqueous solution.)

DI water (pure water): Electrical conductivity 1 μS/cm or more (electrical resistivity 1MΩ・cm or less)

3 Ambient temperature: 32

o

C, (2) Circulating fluid: Clean water, (3) Circulating fluid temperature: 20

o

C, (4) Circulating fluid flow rate: Rated flow

rate, (5) Power supply: 400 VAC

4: (1) Ambient temperature: 32

o

C, (2) Circulating fluid: Clean water, (3) Circulating fluid flow rate: Rated flow rate, (4) Power supply: 400 VAC

5: (1) Ambient temperature: 32

o

C, (2) Circulating fluid: Clean water, (3) Circulating fluid temperature: 20

o

C, (4) Load: Refer to the specified cooling

capacity (5) Circulating fluid flow rate: Rated flow rate, (6) Power supply: 400 VAC, (7) Piping length: Minimum

6: With pressure control function using an inverter. When the pressure control function is not being used, the pump power supply frequency setting

function can be used.

7: Required flow rate to maintain the cooling capacity. When the flow rate is lower than the rated flow, use a by-pass piping set.

8: The anchor brackets (including M8 bolt x 6pcs.) are used for fixation with the skid when this product is packed. The anchor bolts are not attached.

Loading...

Loading...