- 106 -

No.SFOD-OMT0010-B

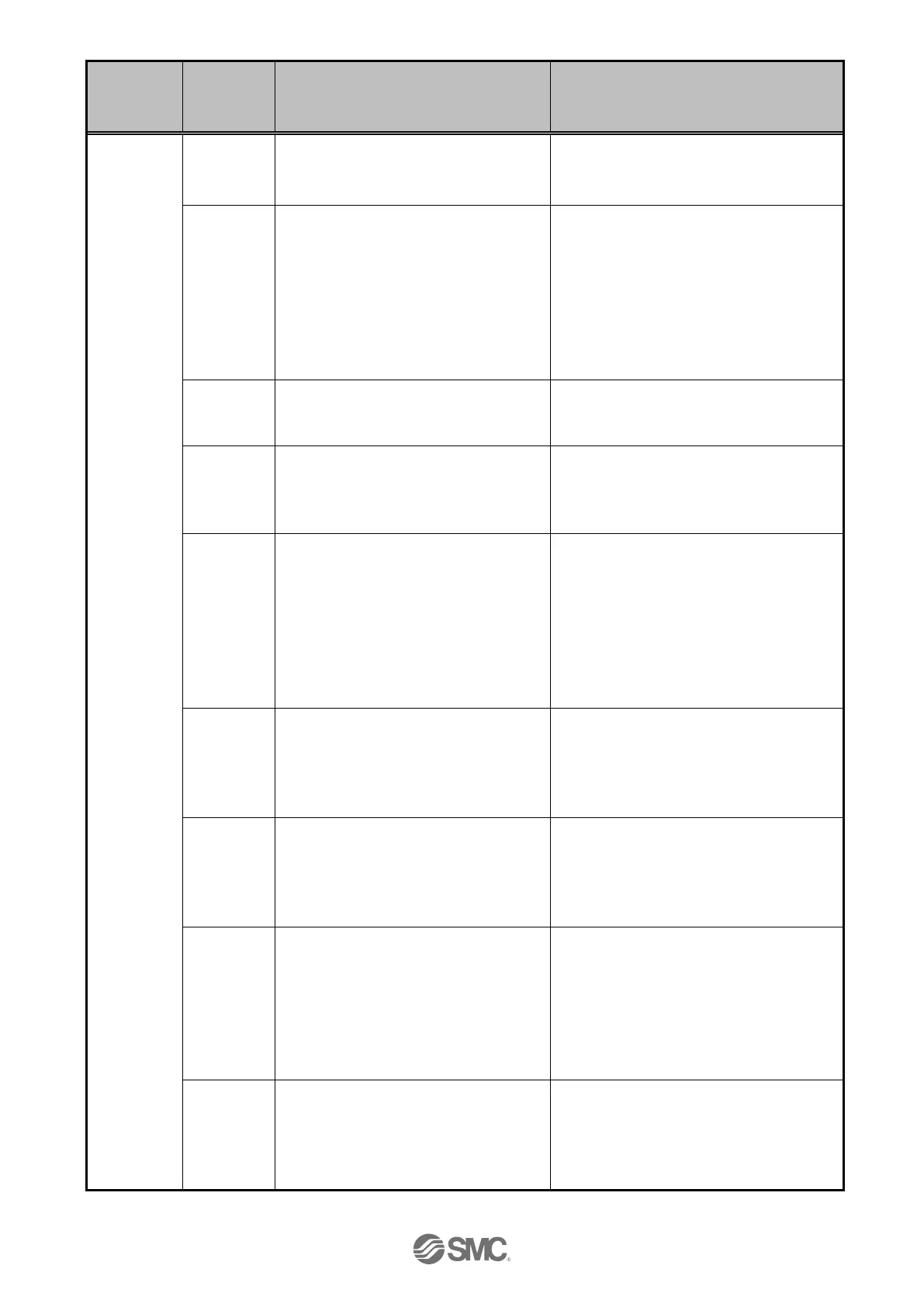

Operation

stops

intermittently

Check if the controller has generated an

alarm? Check the type of alarm, referring

to this manual.

Refer to thismanual and take appropriate

measures.

-> 11. Alarm detection

Check that the wiring is connected

correctly?

Refer to this manual to confirm wiring, and

check for broken wires and short-circuits.

Correct the wiring so that the input/output of

each signal is performed appropriately.

Prepare a separate power supply for the

main control, motor drive and motor control,

and input/ output signals.

-> 2.3 Product configuration

-> 5. Power supply connector

-> 6.4 Parallel I/O Wiring Example

Connect to Ground correctly.

Avoid bundling the cables.

Refer to this manual and take appropriate

measures.

-> 4.4 Mounting

Check that the parameter values are

correct.

Check that the appropriate parameters

are used for the actuators connected.

Modify the values of the parameters and test

the operation.

-> 7. Settings Data Entry

Check for a temporary voltage drop in the

power supply?

(If there is a temporary voltage drop in the

power supply, the EMG terminal in the

motor control power connector will turn

OFF so the actuator will stop. However,

this stop will be released when the

voltage recovers.)

There is a possibility of a momentary voltage

drop because the capacity of the power

supply is insufficient, or if the power supply is

an “inrush-current protection” type.

-> 4. Product Specifications

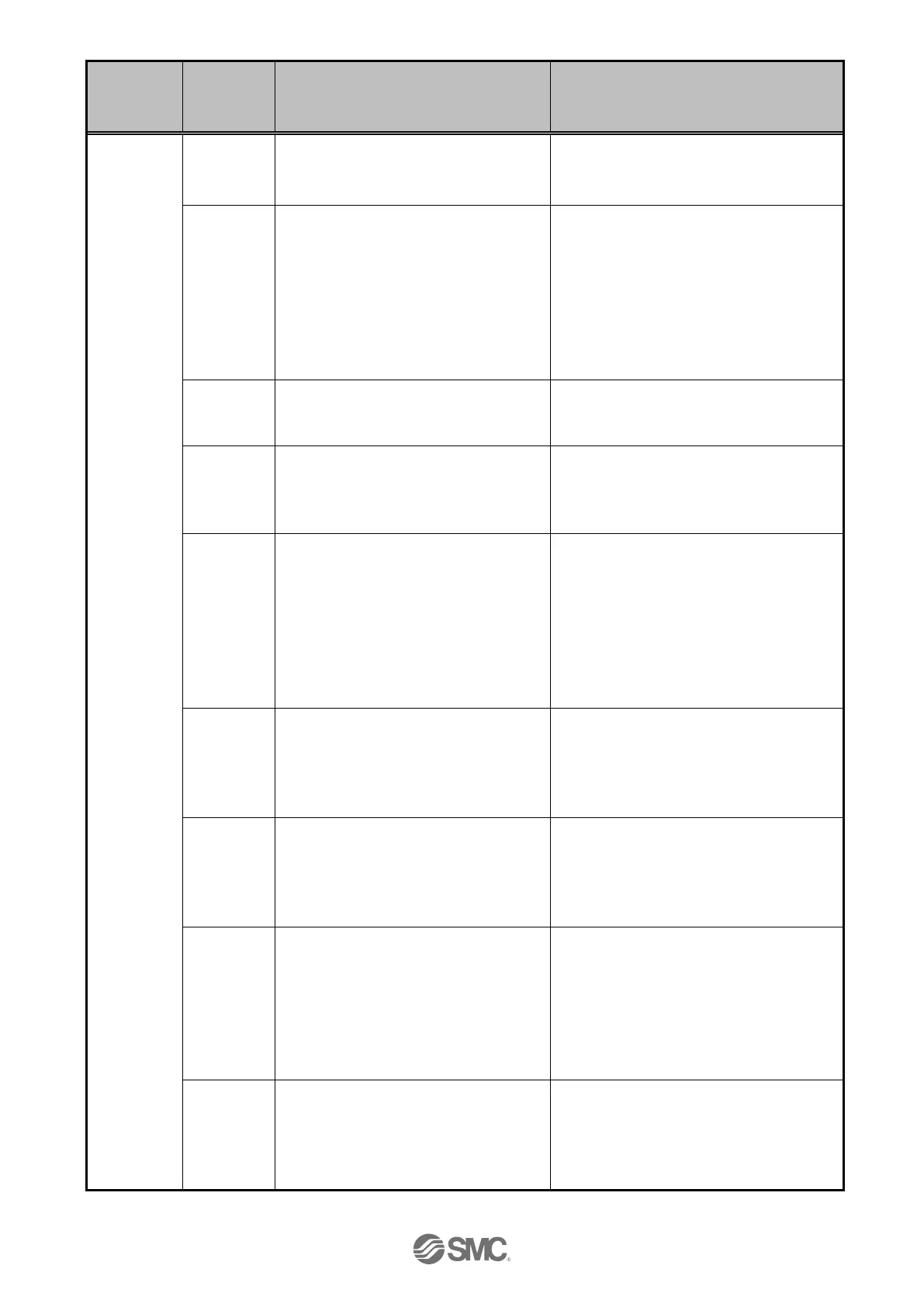

Failure of

pushing

operation.

Check that the INP output turns on during

a pushing operation.

(If completion of the pushing operation is

detected by the INP output, the PLC

cannot confirm the completion).

Check the INP output signal before the

energy saving mode is turned on.

-> 6.3 Parallel I/O signals

Check that the controller parameter

settings for the product model and power

supply specification are appropriate for

the actuator connected.

Check that the controller parameters

matches with the actuator product number.

Check that the power supply specification is

correct,

-> 4. Product Specifications

Check the timing of the signal from the

PLC to the controller.

Leave an interval of 15ms or more

(recommendation is 30 ms) between input

signals and maintain the state of the signal

for 15ms or more (recommendation is 30

ms), because PLC processing delays and

controller scanning delays can occur.

-> 8.7 Controller input signal response time

Check that the Operation was sent after

SVON input is ON and SVRE output is

ON.

When the power is supplied, it may take up

to 20 seconds from servo ON to SVRE ON

depending on the actuator position or

conditions. Send an operation only when the

SVRE output is ON.

Loading...

Loading...