COM communication interface is mainly provided for customization the

second step of development use.The inverter supports the control of

external equipment or external equipment control through

communication.

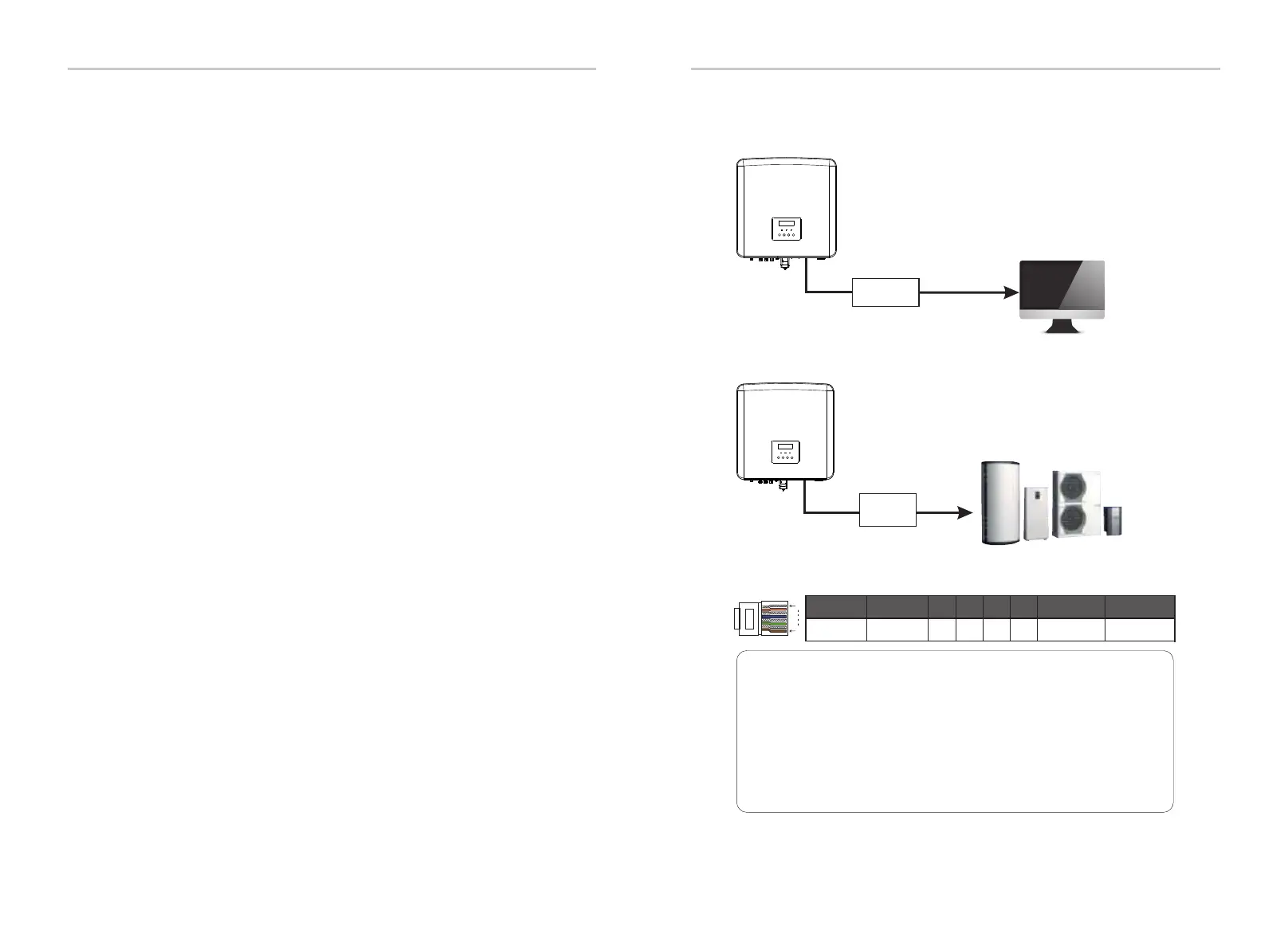

For example, the inverter adjusts the working mode of the heat pump

and so on.

Ø COM PIN Definition

Ø Application occasion

COM is a standard communication interface, through which the

monitoring data of the inverter can be directly obtained. Also, external

communication devices can be connected to carry out the secondary

development of the inverter. For specific technical docking, please

contact us.

Electrical Connection

Electrical Connection

5.5.4 COM Communication

Note!

Customers can communicate or control the inverter and external

devices through the COM interface. Professional users can use

pins 4 and 5 to realize data acquisition and external control

functions. The communication protocol is Modbus RTU. For

details, please contact us. If the user wants to use the inverter dry

contact to control external equipment (such as a heat pump), it

can be used with our's Adapter Box. For details, please refer to the

Quick Installation Manual of the Adapter Box.

1 2 3 4 5 6 7 8

1

8

485A

485B

GND

Drycontact_A(in) Drycontact_B(in) Drycontact_A(out)

Drycontact_B(out)

+13V

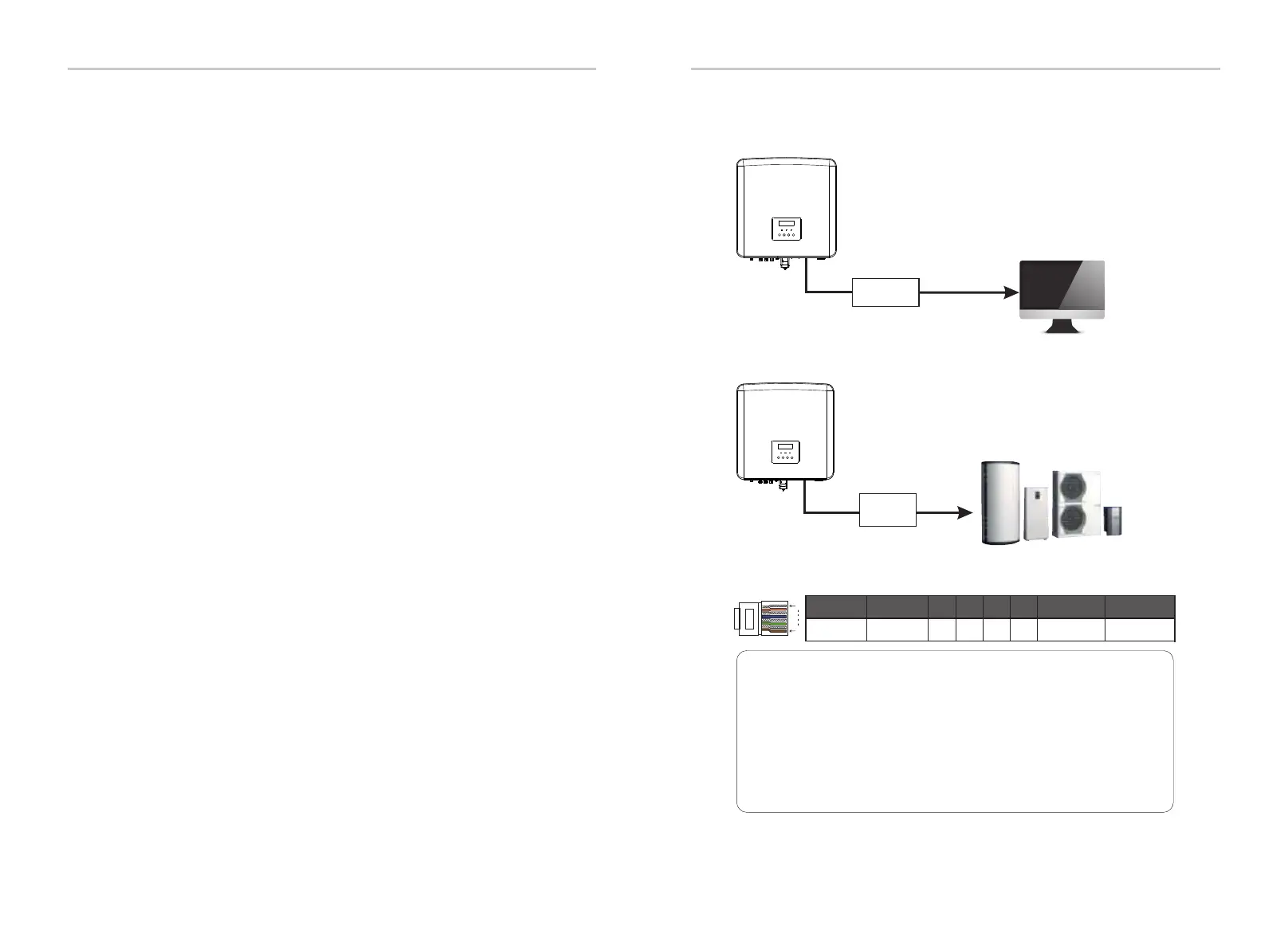

External communication equipment controls the inverter:

Inverter communication control external equipment:

60

61

Date Read

Adapter

Box

Once slave inverter exit from system and be running as an independent

unit, its all setting will be re-excuted.

The rest of this section covers several important parallel control functions,

and the next page table shows which LCD options are controlled by

master inverter and which can work independently.

Off mode setting:

Off mode can only be set by master inverter ( long press ESC button on

LCD ).

Safety setting:

System safety protection is cancelled by master inverter’s safety. slave

inverter protection mechanism will only be triggered by master

inverter’s instructions.

Self-use setting:

If system is running as self-use mode, please note the Feedin Power Limit

set of master inverter is for the overall system and the corresponding set

of slave inverter is invalid.

Power Factor setting:

All sets about power factor are all for the overall system and the

corresponding sets of slave inverter are invalid.

Remote control setting:

The remote demand instructions received by master inverter will be

interpreted as the demand instructions to overall system.

External ATS setting:

INCORRECT line sequence (R-R, S-S, T-T, N-N) will damage the inverter. To

avoid the damage, the default “Disable” has been set to “Enable” in

“External ATS” under “Advance Settings”. Users should set the default

setting back to “Disable”. Because only when a matebox advanced is

connected, External ATS needs to be set to “Enable”.

USB to RS-485

converter

Loading...

Loading...