INSTRUCTION MANUAL

SPACE s.r.l.

ER 200 - ER 220

ER150 - ER160 - ER165

Code M0076 - rev.1.6

(04/2005)

SPACE s.r.l. – 10090 Trana (TO) Via Sangano, 48 Page 21/ 40

Tel. (+39) 011/ 933.88.65 – Fax (+39) 011/ 933.88.64

e-mail: info@spacetest.com

7.3.2 Wheel positioning

The weights must be positioned in the top part on the vertical, at 12 'o' clock, so unbalance is

below and the weight fitting point is above.

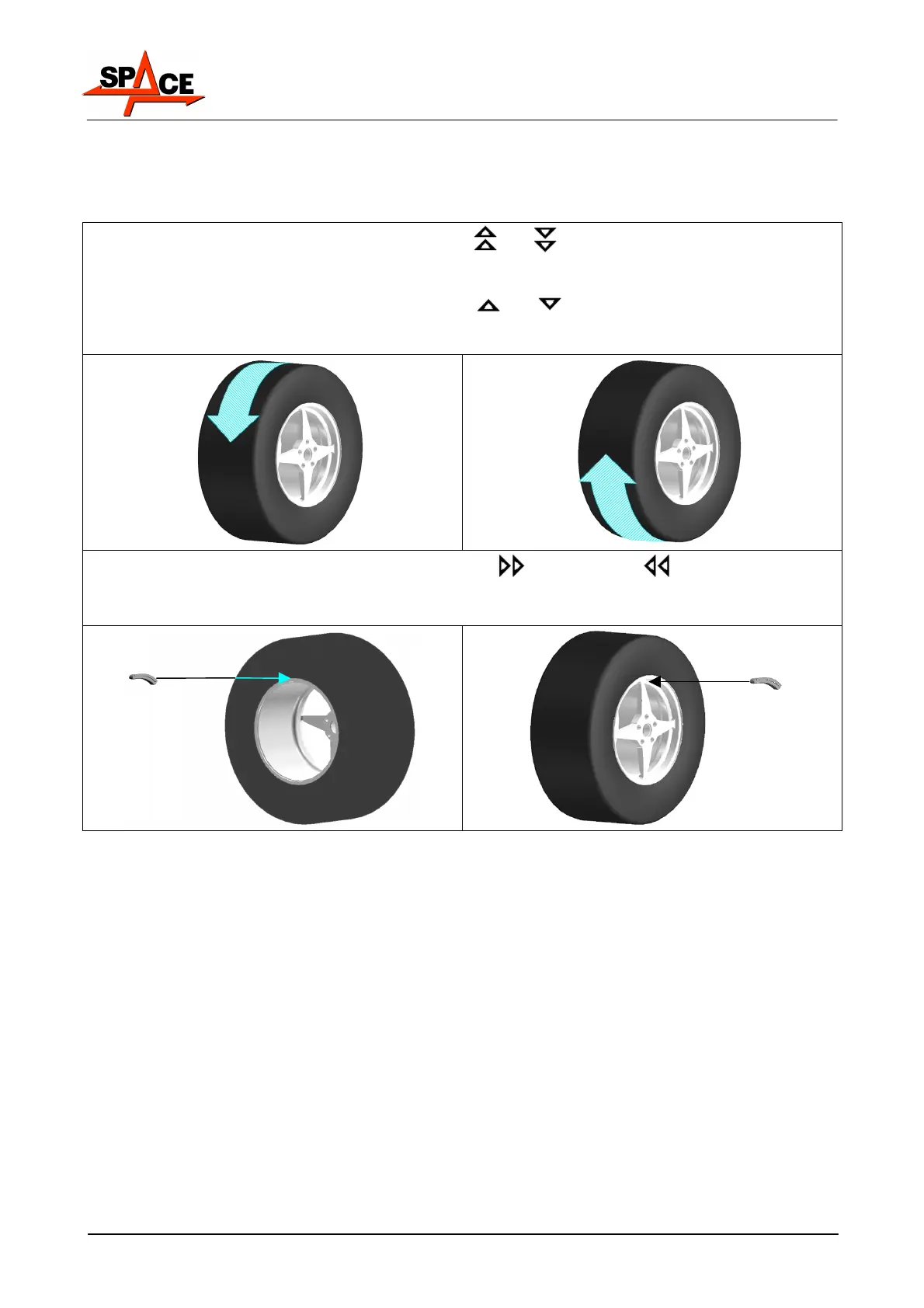

When the wheel balancer display screen shows

or this means you are

very far

from

the point where the counterweight is to be positioned.

The position of the wheel is over 30° from the exact fitting point.

When the wheel balancer display screen shows

or this means you are

not far

from

the counterweight positioning point.

The position of the wheel is within 30° of the exact fitting point.

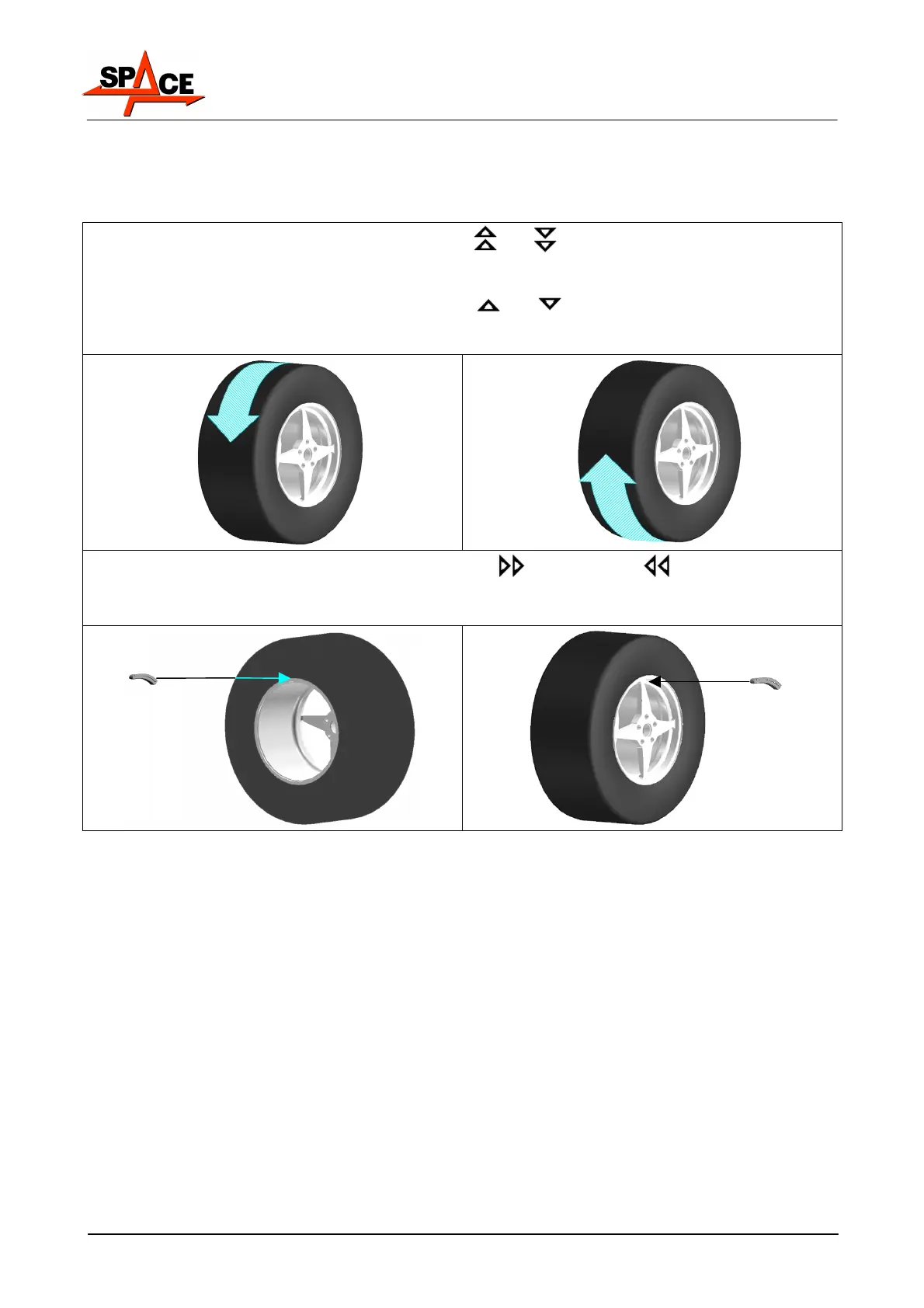

When the wheel balancer display screen shows (inside) and (outside) the exact

position has been reached. The fitting point has been found. Now the unbalance can be

corrected by fitting the necessary weight.

Once the wheel has been correctly positioned, fit the weight indicated by the machine on both

sides of the wheel.

After the weights have been fitted, the wheel balancing conditions can be checked by

performing a trial wheel spin.

The STANDARD unbalance calculation procedure is now completed.

Loading...

Loading...