6

•

1 – 100% duty cycle adjustment for PulsaJet and other electric spray nozzles.

•

Oers easy to use ming modes of Fixed Spray Time; Variable Spray Time, and Repeat.

•

Can control and drive up to ten (10) Spraying Systems Co.

®

electric spray nozzles

•

AA10000AUH-03 PulsaJet® spray nozzles – Ten (10)

•

AA10000JJAU PulsaJet air atomizing spray nozzles – Ten (10)

•

AA10000AUH-10 PulsaJet spray nozzles – Three (3)

•

AA10000AUH-30 PulsaJet spray nozzles – One (1)

•

AA250AUH Electric spray nozzles – Ten (10)

•

Ambient temperature rangs for electric control panel:

•

41°F Minimum (5°C)

•

104°F Maximum (40°C)

•

Dimensions: 9” (228.6 mm) x 4 1/4” (108 mm) x 10 1/2” (266.7 mm)

For Internaonal applicaons be sure that you have the correct power cord.

PRECISION SPRAY CONTROL (PSC)

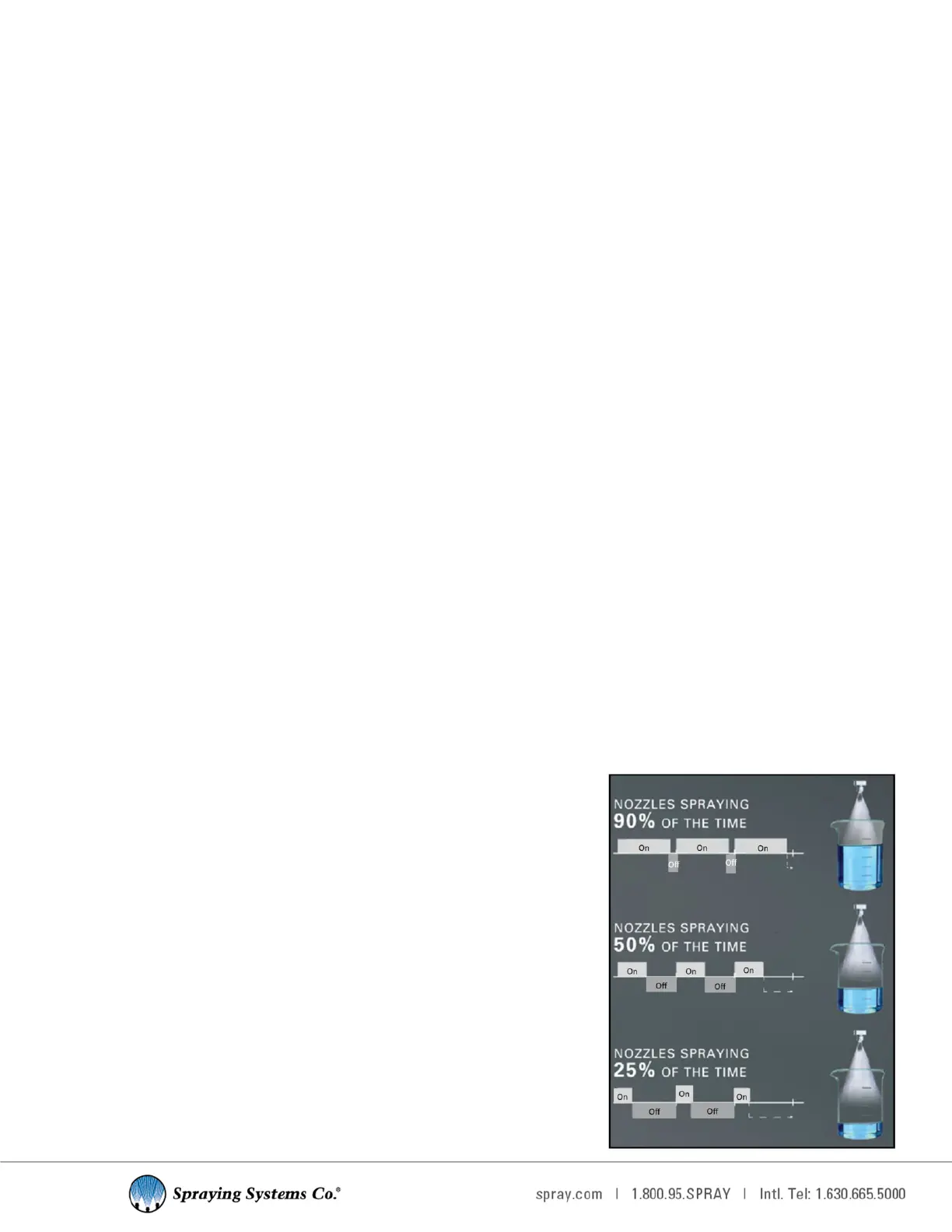

The PulsaJet® automac spray nozzle is an electrically-acvated hydraulic, atomizing nozzle. This nozzle sprays the

product in a controlled way using a PWM algorithm to control the sprayed amount without aecng the spray angle.

PWM is the fundamental control principle that allows a signicant reducon in ow by regulang the relaonship

between the on/o mes that the nozzle operates.

Short pulses of on-me and longer pulses of o-me produce a spray paern that appears connuous, but actually

reduces the overall ow delivered to the target surface. This provides beer ow control with larger spray ps that are

less prone to clogging. The droplet size is aected by the pressure of the liquid. With PSC, the droplet size and spray

angle are independent of the liquid ow because the nozzle can work at the same liquid pressure for variable liquid

ows.

PSC involves switching the spray nozzle on and o repeatedly at a controlled rate, called the modulang frequency.

The modulang frequency is the number of mes the nozzle is switched on and o in one second and is measured in

Hertz (Hz). If a spray nozzle is switched on and o 10 mes per second, the modulang frequency is 10 Hz. The me

from when the nozzle turns on to the next me the nozzle turns on is called the period, in this case 1/10th of a second.

Within a single period, the nozzle is switched on, then o. The me that the nozzle is on, divided by the total me of

the period, gives a percentage which is called the duty cycle. For example, if the period is 0.10 seconds, and the nozzle

is on for half of that me, then the duty cycle is 50%. For the same period, if

the nozzle is on for 0.08 seconds then the duty cycle is 80%. Therefore, at an

80% duty cycle, the ow will theorecally be 80% of the maximum ow rate

(= 100% ow rate) at a given pressure for the nozzle. Using PSC, the ow rate

for a spray applicaon can be easily controlled without the need to adjust the

spray pressure or spray p.

Loading...

Loading...