Installation, Operation, and Maintenance Manual

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 5

pump and isolation valve. The isolation valve is used for priming, starting, and

shutting down the system. If you use pipe diameter increasers, place them

between the pump and the check valve.

ALIGNMENT

The alignment at the pump and drive shaft is one of the most important

considerations in the pump installation.

WARNING!

Lock out pump driver. Failure to do so

could result in serious personal injury.

TO ALIGN THE PUMP

1. Use flexible spacer couplings to achieve proper alignment.

2. Check and adjust the parallel and angular alignment to within .005 inches

prior to connecting the coupling halves.

3. Jog the motor to check rotation. Its arrow should match up with the arrow on

the pump.

4. Install a coupling guard when the pump is aligned.

Pumps in hot service will need an alignment check at operating temperatures.

STUFFING BOX

Packed Box

Braided packing is supplied as standard equipment on all pumps. Install gland

bolt nuts finger-tight only. Adjust the gland bolt nuts during start-up to achieve

40-65 drops of leakage per minute. Specific packing type is dependent on pH,

temperature, etc. of the liquid being pumped.

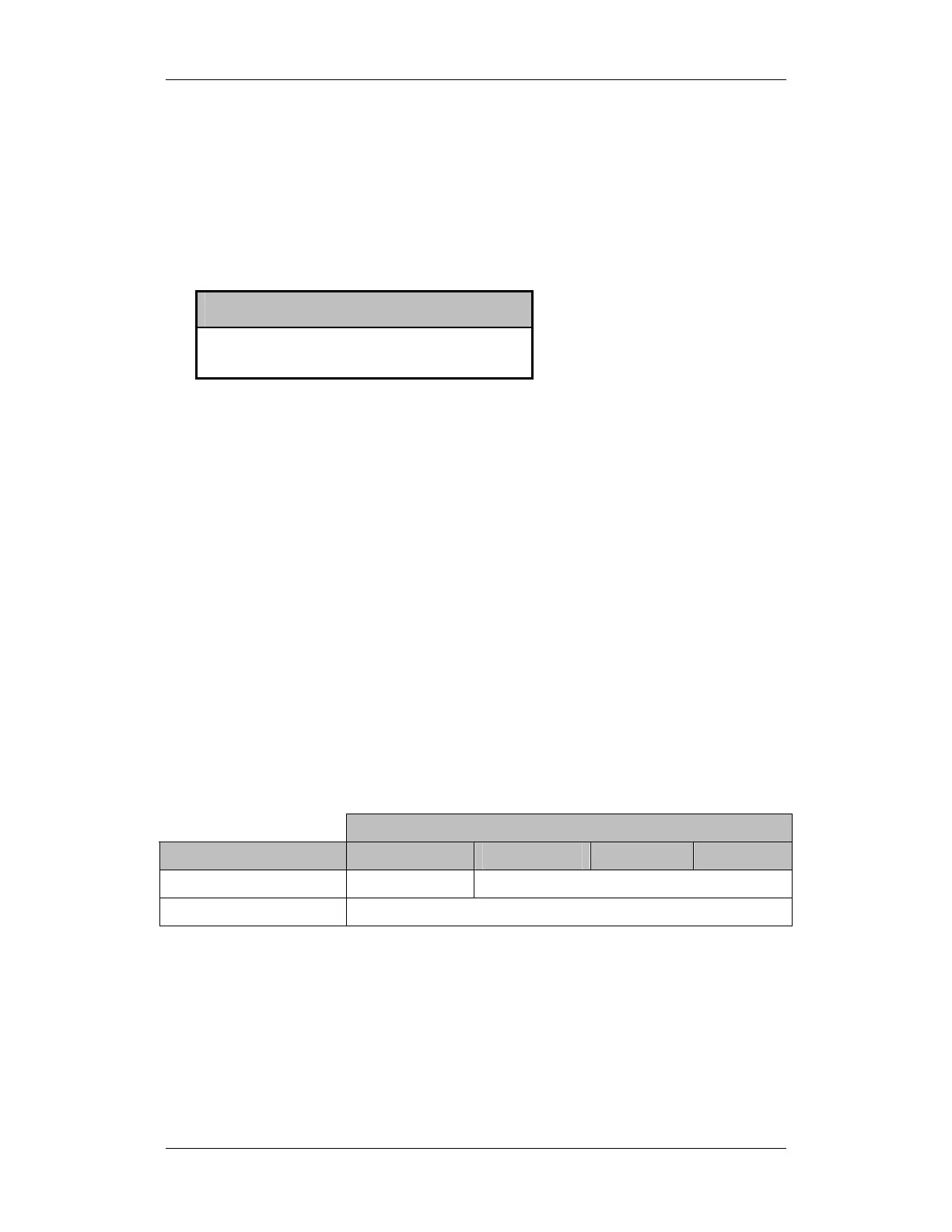

Table 1

Pump Model

STO MTO LTO XLO

Packing Size 7/16 5/8

Number of Rings 5

Clean and cool pumpage may be used to lubricate the packing. If the pumpage is

not suitable, you must supply an external source of lubrication.

Loading...

Loading...