Installation, Operation, and Maintenance Manual

8 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

4. OPERATION

LUBRICATION

CAUTION!

PUMPS ARE SHIPPED WITH NO OIL IN

THE BEARING FRAME! Oil must be

installed before operating the pump.

Ball bearings are very sensitive to both over and under lubrication, both being

detrimental to bearing performance. Either case is detrimental to bearing

performance. Use a thermometer to determine overheating. Excessive overheating

will reduce bearing life.

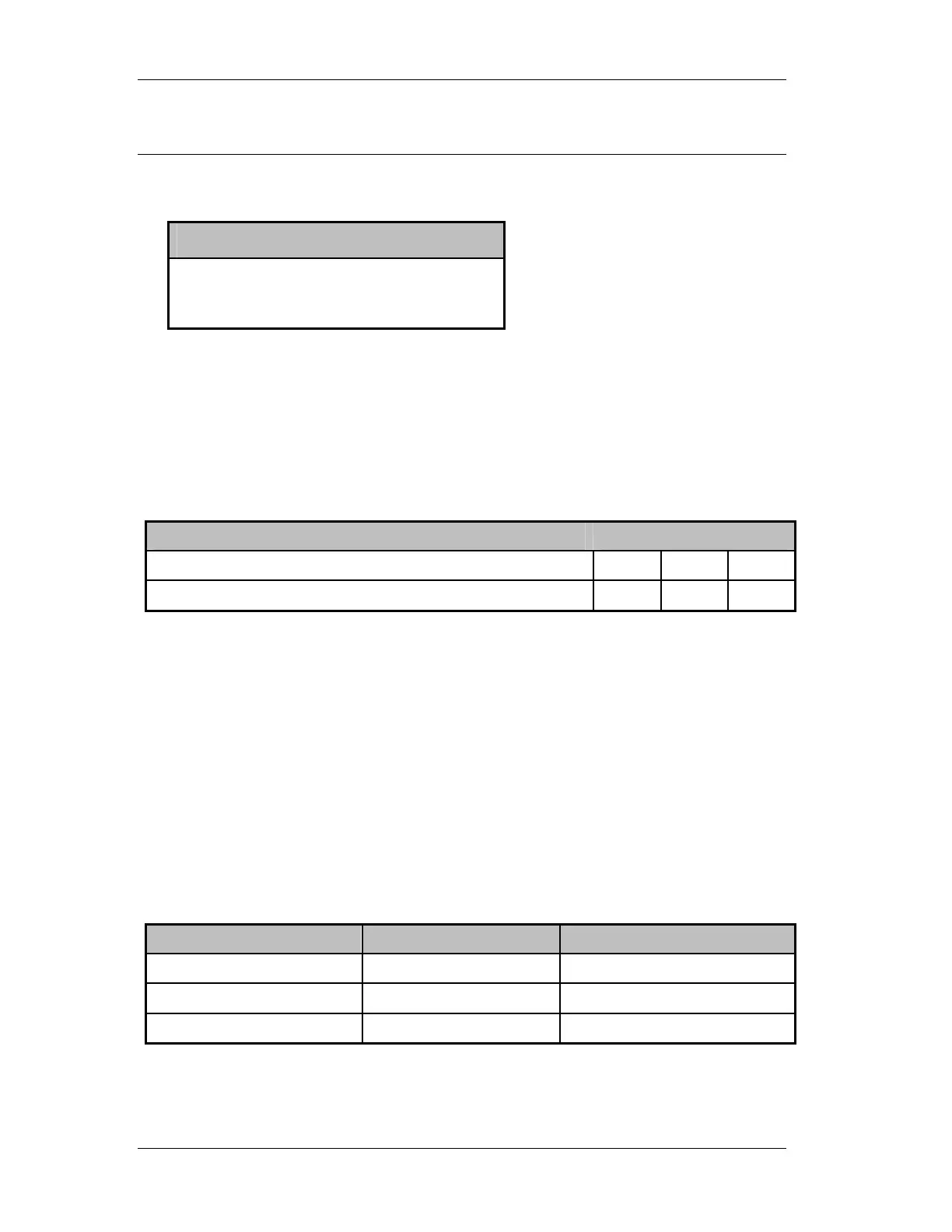

The relationship between temperature and pumpage temperature is an indication of

performance. Table 2 indicates the relationship between these temperatures.

Table 2

Degrees Fahrenheit

Pumping liquid temperature

60° 200° 300°

Approximate normal line bearing temperature

115° 140° 160°

The information shown in Table 2 is based on a room temperature of 70°F. Maximum

bearing temperature is 175°F. The temperatures shown above have a tolerance of plus

15°F. It is necessary to flush water on the shaft for liquid temperatures above 250°F.

This can be done either through a flushing gland or the stuffing box seal cage.

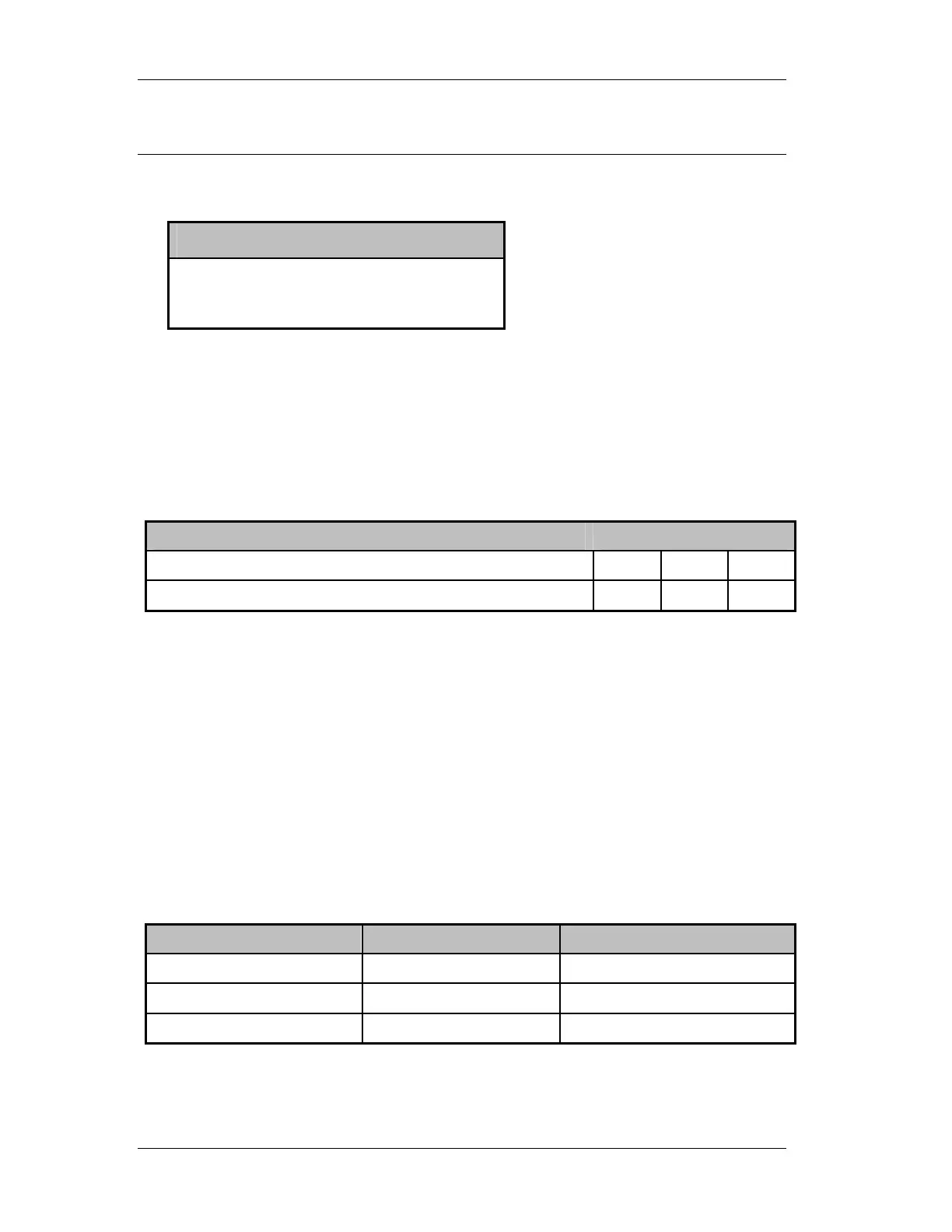

Oil Lubrication

Use only high quality turbine oil with rust and oxidation inhibitors. Service

temperatures determine oil viscosity. See Table 3.

Use a 300 SSU viscosity at 100° F for applications where pumping temperatures are

below 200° F. At pumping temperatures above 350° F, use 470 SSU at 100° F with

optional cooler.

Table 3

Bearing Temperature ISO Grade Viscosity at 100 Degrees F

Up to 150° F

46 215 SSU

150° F to 200° F

68 300 SSU

Above 200° F

100 470 SSU

Grease Lubrication

Regrease grease lubricated bearings with NLG1 No. 2 consistency grease for

Loading...

Loading...