Installation, Operation, and Maintenance Manual

12 SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796

APPENDIX A - IMPELLER CLEARANCE SETTING

A gradual loss in head and/or capacity can occur. You may restore performance by

adjusting the impeller clearance, which is the measurement between the impeller

vanes and the surface of the casing.

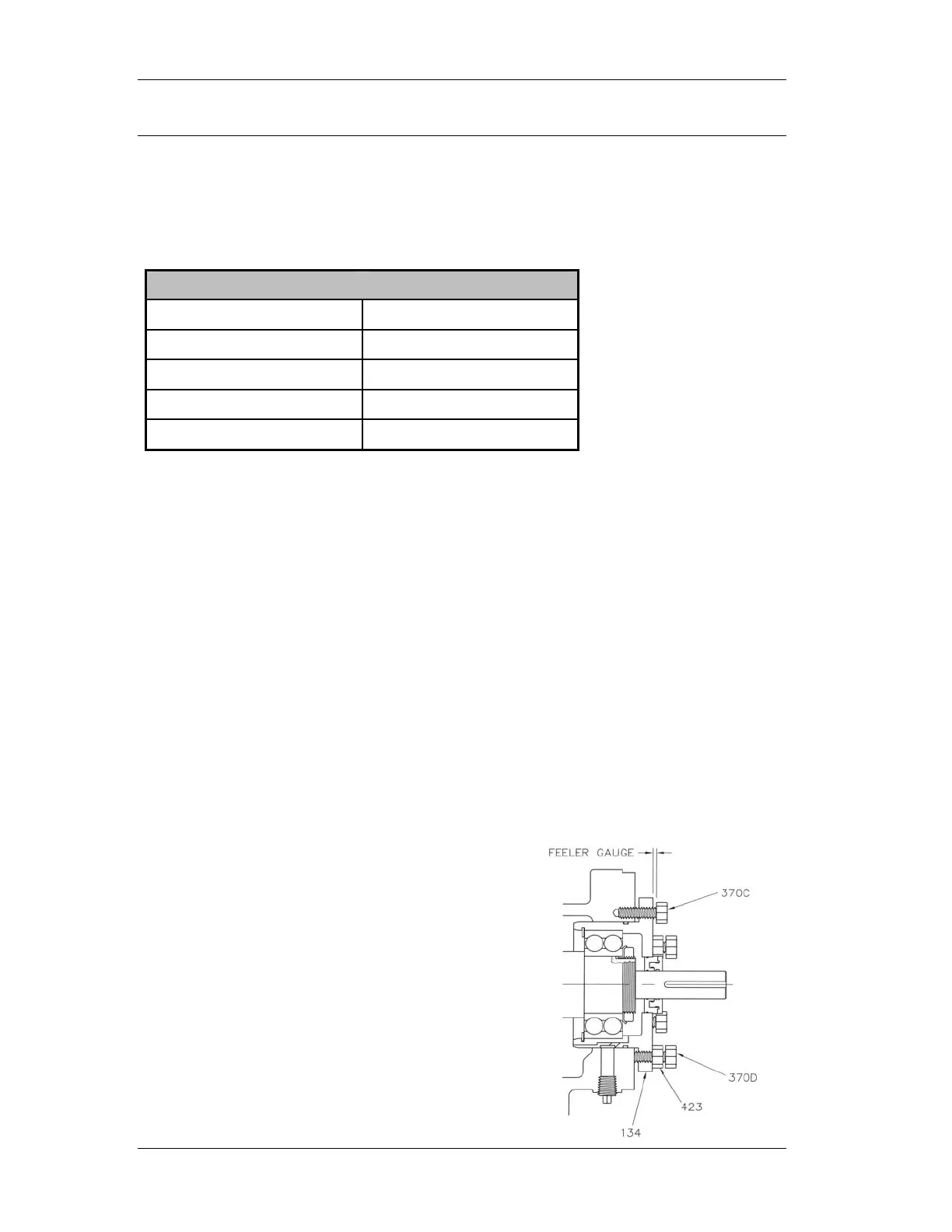

Table 6

Temperature Impeller Clearance

200° F (93°C)

.015” (.38 mm)

250° F (121°C)

.017” (.43 mm)

300° F (144°C)

.019” (.48 mm)

350° F (177°C)

.021” (.53 mm)

400° F (204°C)

.023” (.58 mm)

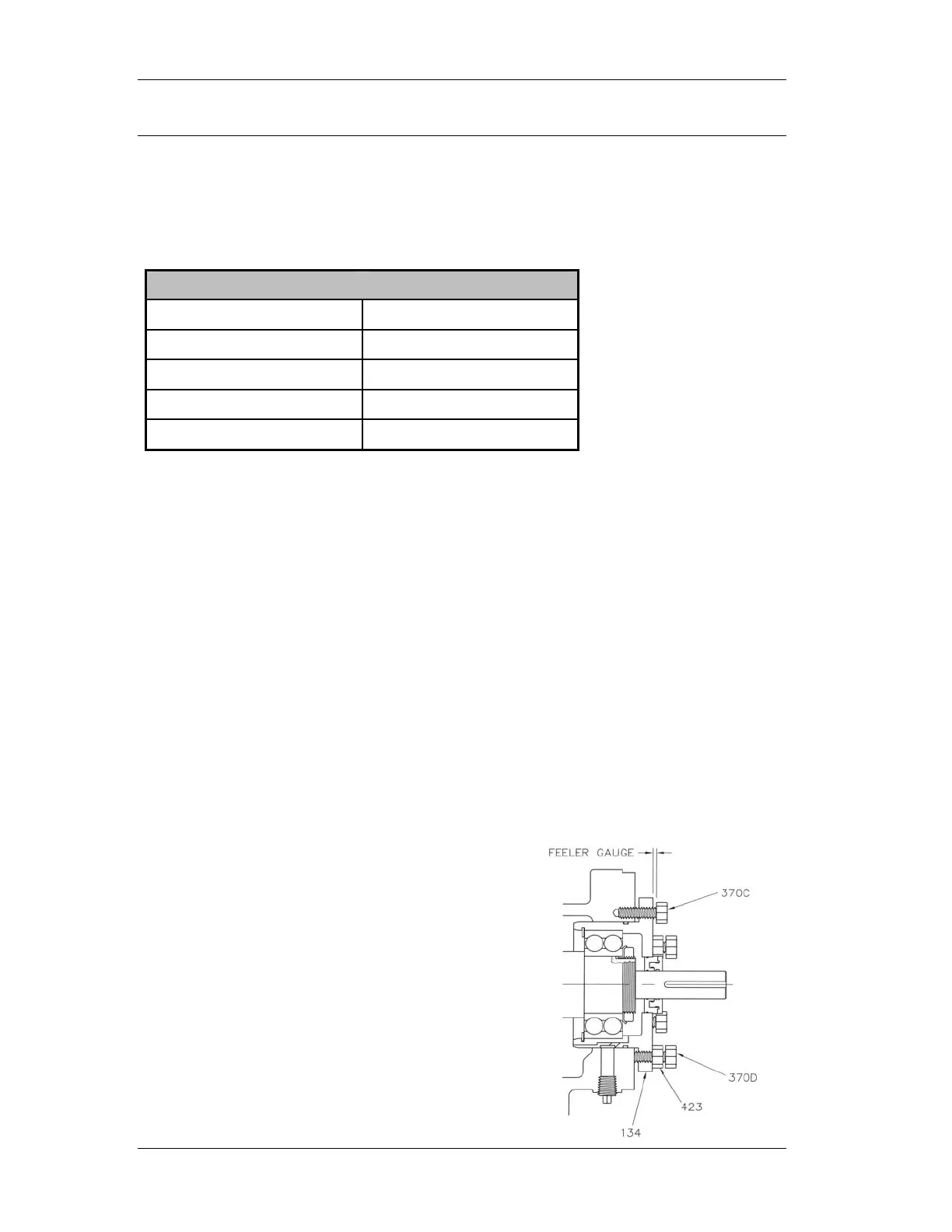

FEELER GAUGE TECHNIQUE

Models 2196, 2196-LF and 2796

TO USE THE FEELER GAUGE TECHNIQUE FOR IMPELLER CLEARANCE SETTING

FOR MODELS 2196, 2196-LF & 2796

1. Lock out power to the pump driver.

2. Remove the coupling guard.

3. Loosen jacking bolts (370D) and jam nuts (423).

4. Tighten bearing housing bolts (370C) evenly, while slowly rotating the shaft until

the impeller starts to rub on the casing.

5. Using a feeler gauge, set the gap between the 3 housing bolts (370C) and the

bearing housing (134). (Refer to Table 6 for settings.)

6. Tighten jack bolts (370D) evenly until bearing housing backs out and contacts the

bearing housing bolts (370C).

7. Tighten jam nuts (423) evenly, rotating the shaft to make sure the assembly turns

freely.

8. Reinstall the coupling guard.

9. Unlock power to the pump driver.

Loading...

Loading...