Installation, Operation, and Maintenance Manual

SUMMIT PUMP MODEL 2196 / 2196-LF / 2196-R / 2796 9

pumpage temperatures -60° F to 350° F. Grease is not recommended for temperatures

above 350° F. Regrease bearings every three months.

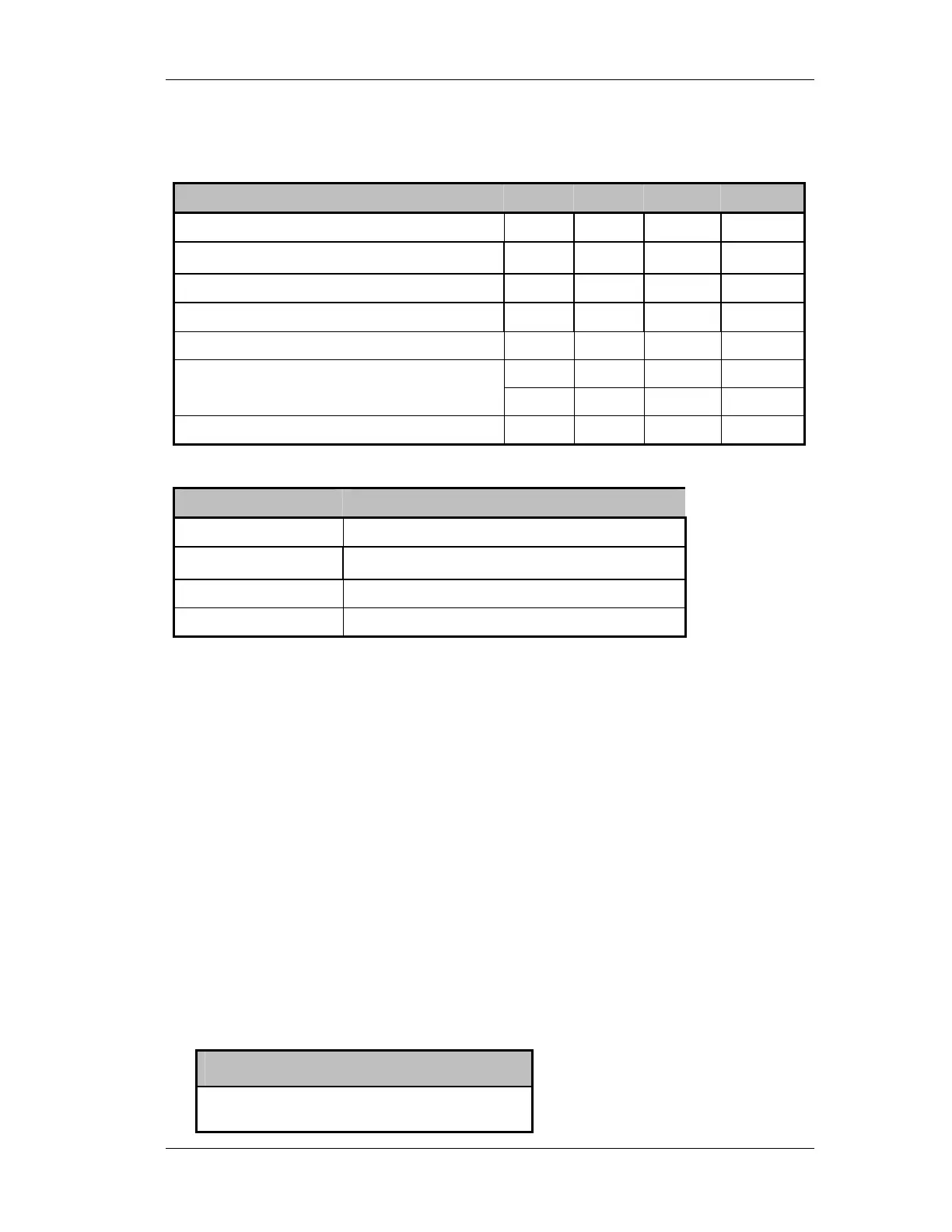

Table 4

Acceptable Lubricating Oils

ISO VG 32 46 68 100

Keystone: KLC Antiwear 32 46 68 100

Lubriplate AC0 AC1 AC2 AC3

Mobil: DTE Light - Medium Heavy

Mobil: Synthetic 624 525 626 627

Phillips: Magnus 32 46 68 100

Synthetic, syndustrial mist 100

Shell: Tellus Fluids HD 32 46 68 100

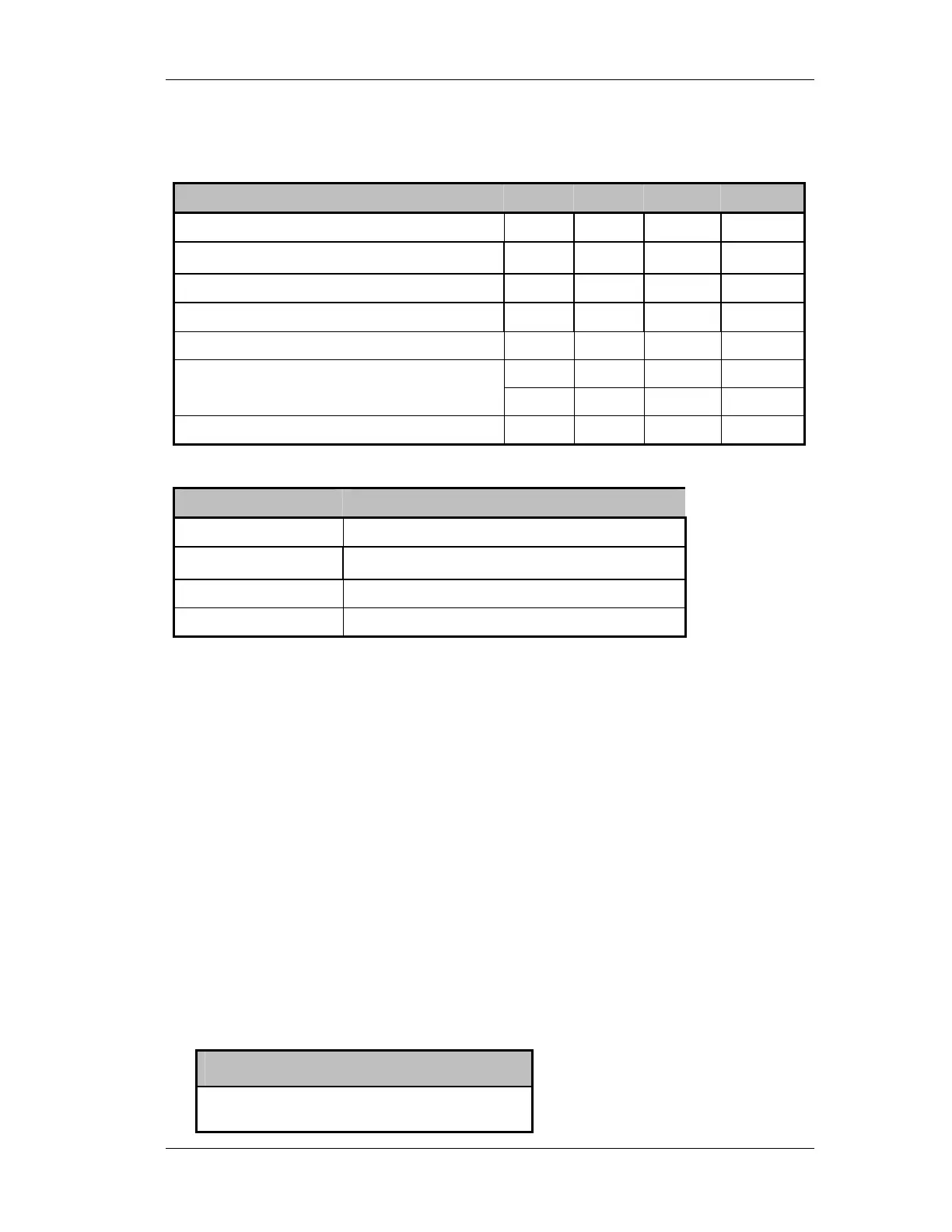

Table 5

Acceptable Greases

Citgo Mystic EP2

Keystone 81EP2

Mobil Mobilux EP2

Mobil Synthetic SCH 100

TO REGREASE LUBRICATED BEARINGS

1. Wipe dirt and foreign matter from the fittings.

2. Remove grease relief plugs from the bottom of the frame.

3. Fill grease through fittings until it comes out through the relief holes.

4. Reinstall grease relief plugs.

ROTATION

TO ROTATE THE PUMP

1. Lock out power to the pump driver.

2. Remove the coupling guard and coupling.

3. Momentarily restore power and energize the motor to determine rotation.

4. Confirm that motor rotation coincides with proper pump rotation. The proper

pump rotation is counterclockwise when facing the pump’s suction. Lock out

power to pump driver.

WARNING!

Operating the pump in the opposite

rotation may dislodge the impeller

Loading...

Loading...