30

11) Input of the compressed air and control of the air pressure (HA type)

[Caution]

For safety, be sure to turn the power off during adjustments.

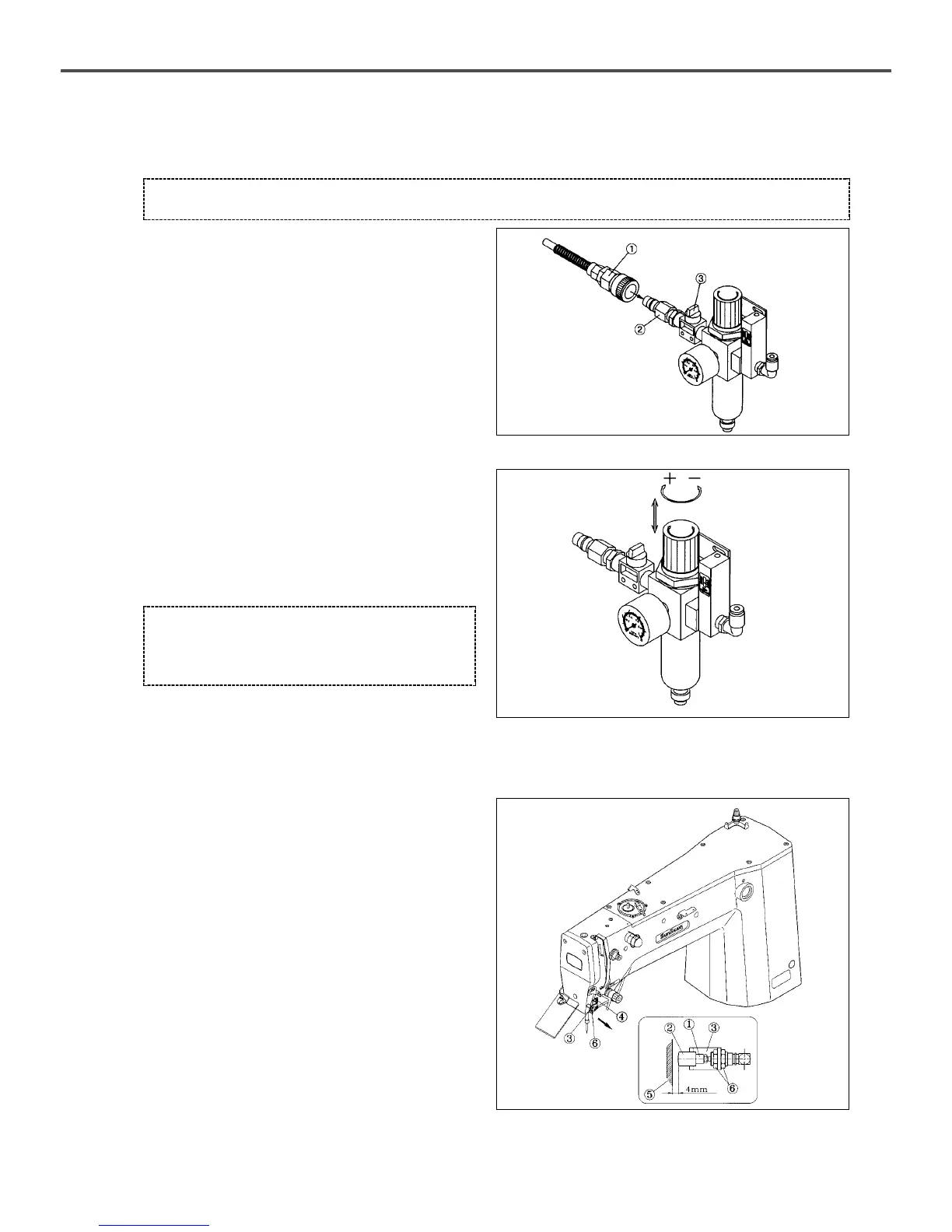

[Figure 56]

A. Connect the quick joint socket① where pressed air

is connected to, with the quick joint plug② mounted

to the table.

B. Open the finger valve③ to put in the compressed air.

[Note]

When you close the finger valve after use, the remaining

air will be discharged automatically and the remaining

pressure will be indicated as 0 MPa (0kgf/cm

2

)

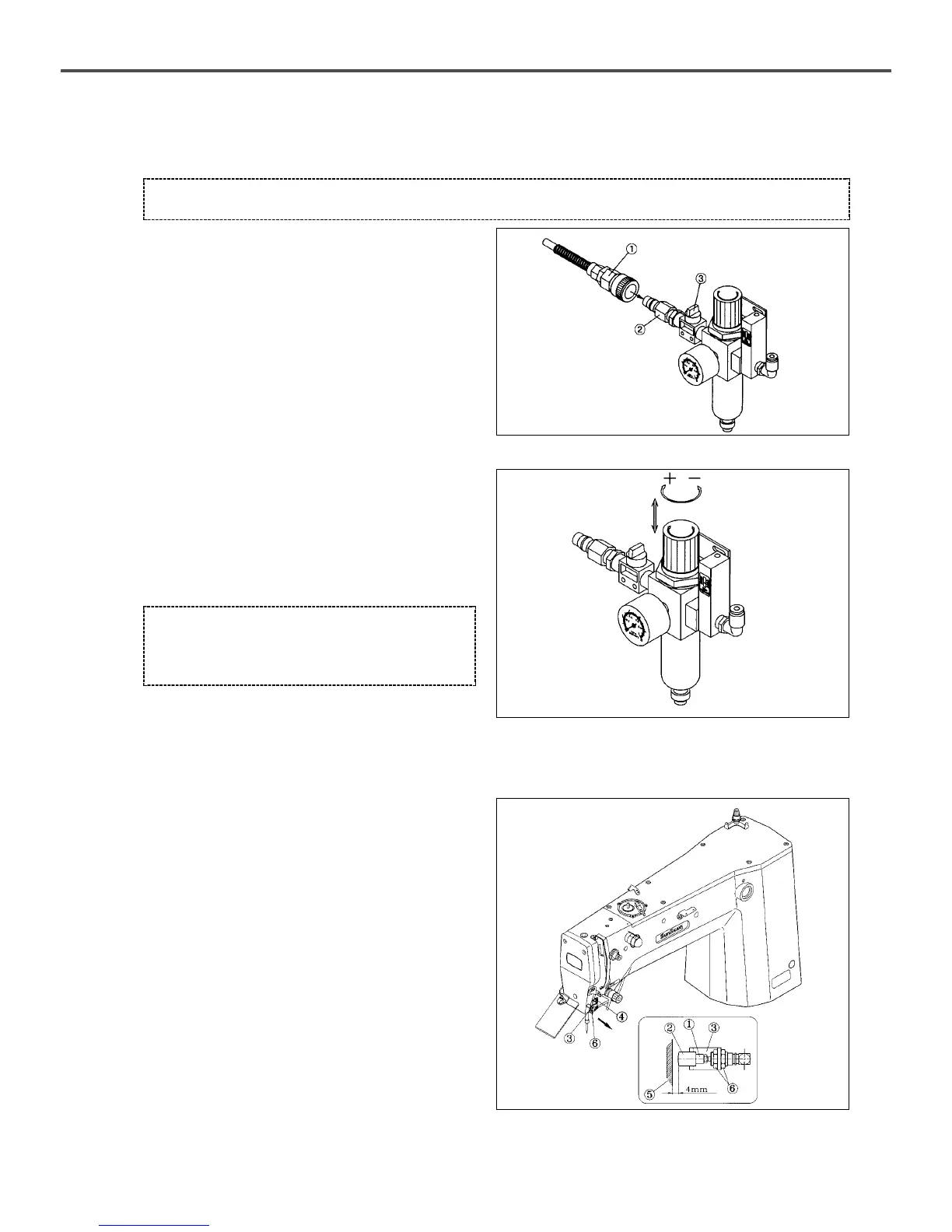

[Figure 57]

C. Pull the control handle at the upper part of the filter

regulator as shown above and turn it clockwise to increase

pressure and counterclockwise to decrease pressure.

After setting the pressure at 0.49~0.54MPa (5~5.5

kgf/cm

2

) as indicated on the pressure gauge, press back

and fix the control handle to its original position.

[Caution]

If the air pressure drops (under 4 kgf/cm

2

) during use,

the error sign [Er07] will appear and the machine will

stop automatically.

12) Control of the upper thread holding device (optional)

A. Check if the pin cylinder knuckle① and the cap② of

the upper thread holder are positioned at the center

of the upper thread passage.

B. If they are not at the center, loosen two screws④ of

the pin cylinder bracket③ to bring them towards the

center. Fasten the screws afterwards.

C. The recommended distance between the end point

of the knuckle cap② and the ARM⑤ is 4mm.

D. To adjust the clearance, unfasten two pin cylinder

nuts⑥ for adjustment and fasten them afterwards.

[Figure 58]

Loading...

Loading...