33

5) Adjustment of the presser foot height

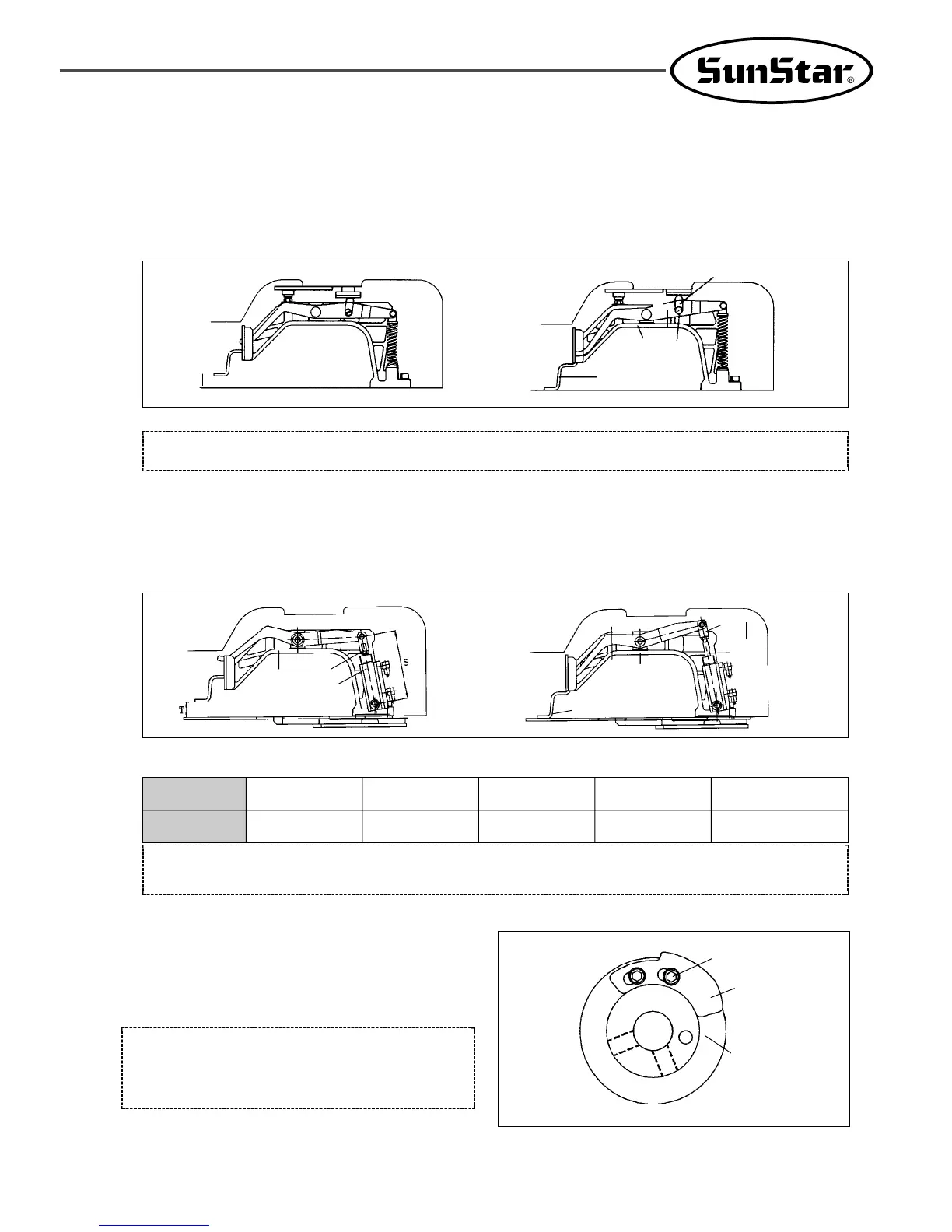

A. For general, thick, thin or knitted materials

Unfasten the screws② of the lift lever control plate on the left and right side of the feed bracket①. When you raise

the control plate③ to the A direction, the height of the presser foot④ will go down and to the B direction, the height

will go up. After fine-tuning the height, securely tighten the screws②.

B. For air-pressure type (HA type)

Unfasten the cylinder knuckle nut③ attached to the left and right cylinder② of the feed bracket①. When you turn

the cylinder axis④ to move the cylinder knuckle⑤ up towards the A direction, the height of the presser foot⑥ will

decrease, and when you move it down towards the B direction, the height will increase. After adjustments, securely

fix the cylinder knuckle nut③.

The value of cylinder adjustment to presser foot height

[Figure 64]

[Figure 65]

[Caution]

Fasten all the screws tightly after adjusting the height of the presser foot.

[Caution]

When adjusting the presser foot height over the maximum value (14mm), be sure to remove the wiper unit.

6) Adjustment of thread release-related parts

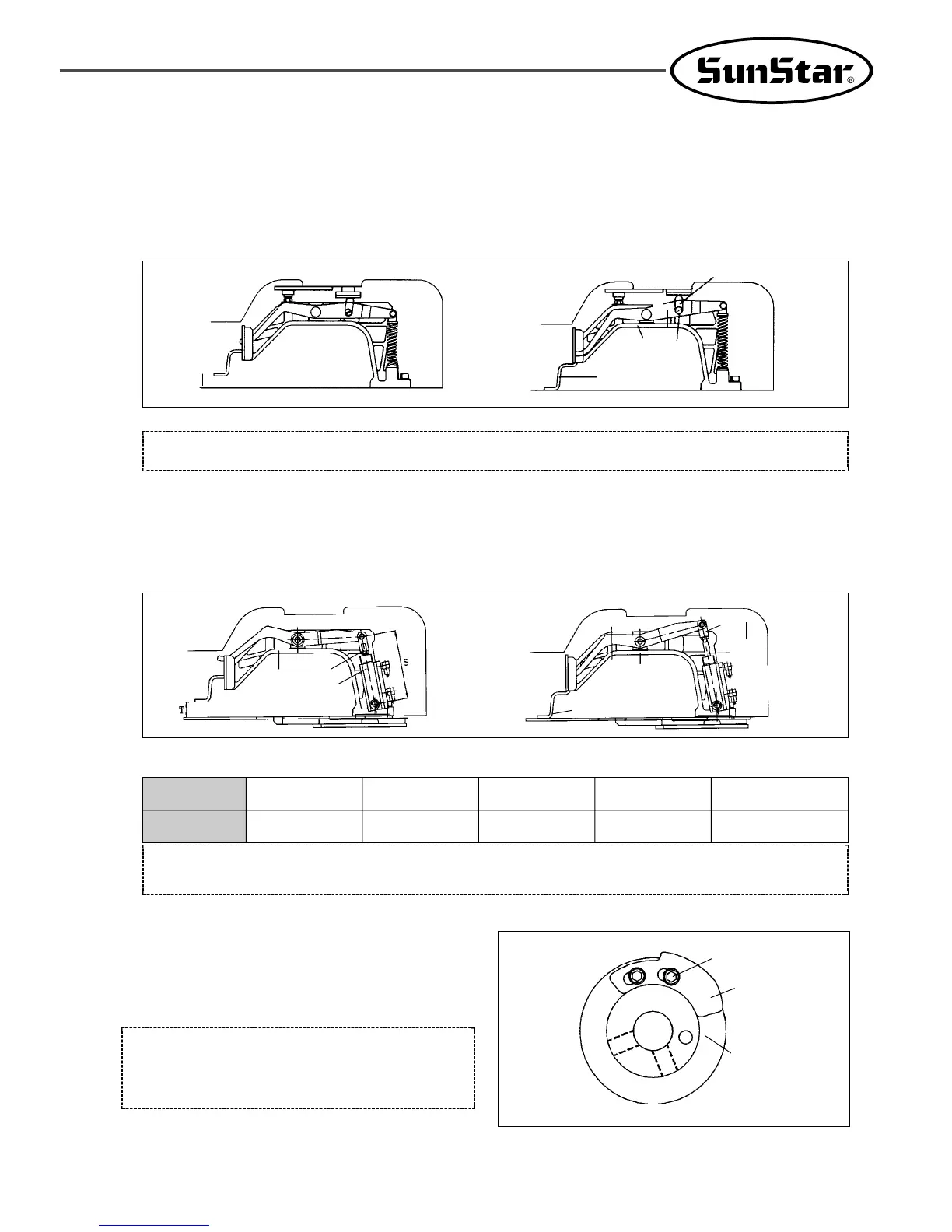

A. Setting the position of the thread release notch

Place the notch so that the right side of a slot of the

thread release notch① touches the circumference of

the notch screw②, and fix with a screw.

[Figure 66]

[Caution]

If the positioning is not correct, the remaining length of

the thread may be too short or inconsistent, and/or the

thread may come out of the needle when sewing starts.

①

Thread Trimmer Cam

②

↓

↑

Max. 17mm

③

①

A

B

④

②

①

⑤

④

⑥

③

②

A

B

T

14

85.4

15

84.5

16

83.7

17

82.8

18

82.0

S

Loading...

Loading...