31

66

Maintenance and repair

Warning

The machine is set to be in optimal condition when it is shipped out from the factory. Do not make

arbitrary adjustments to the machine and replace only with standard OEM parts approved by SunStar.

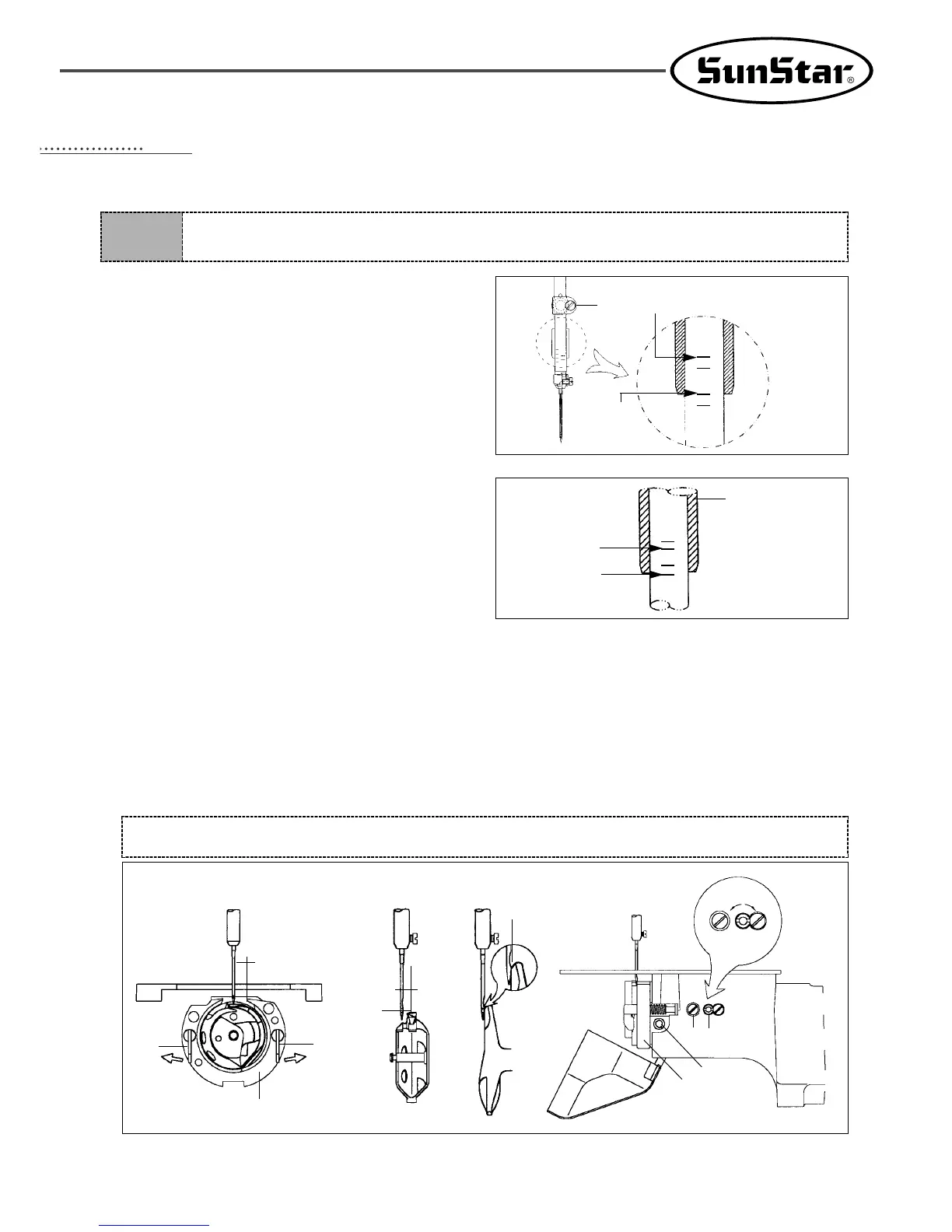

1) Adjustment of the needle bar height

Unfasten the needle bar holding screw① when the

needle bar is at its lowest position. Fit the upper carved

line (one that is suitable for the needle used) with the

lower side of the needle bar bushing to adjust the height

as shown in the Figure. Firmly tighten the screw①

afterwards.

[Figure 59]

[Figure 60]

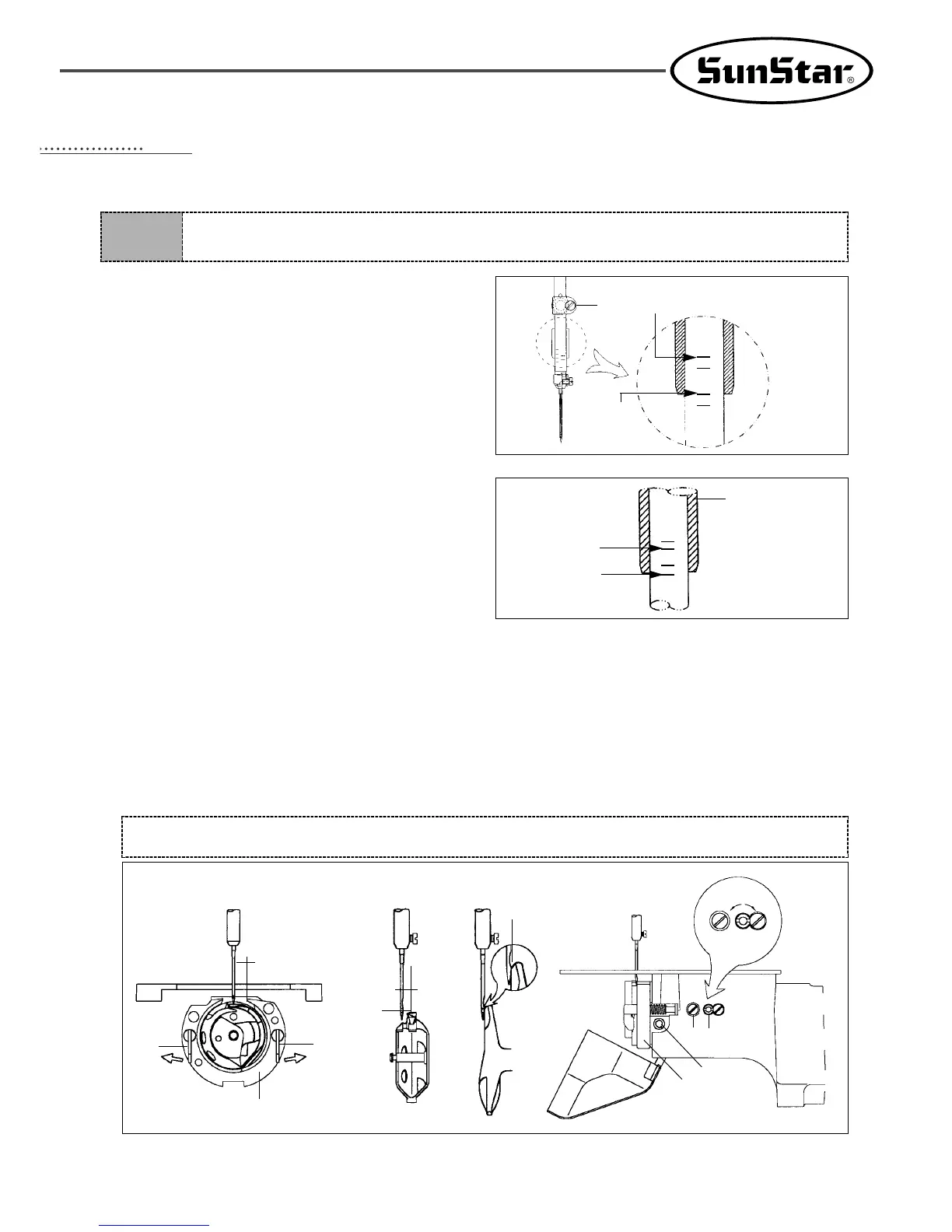

2) Adjustment of the needle and the shuttle

A. At the lowest point of the needle bar, fit the lower

carved line (one that is suitable for the needle used)

with the lower side of the needle bar bushing as

shown in the Figure.

[Figure 61]

[Caution]

For safety, make sure to firmly tighten all the screws after shuttle (large) adjustments.

Needle Bar

Lower Bushing

DP×5

DP×17

7.5mm

②

②

⑥

③

→

→

0.05~0.1mm

→

→

⑤

①

④

0mm

DP×17

DP×5

①

B. After loosening the shuttle driver screw①, open the inner hook pressure bar② left and right to take the shuttle race

ring③ out from the shuttle (large)④.

C. Make sure the shuttle hook point is parallel to the needle center. Be sure to press the needle and the front side of

the shuttle driver firmly together to prevent the needle from bending. Then, tighten the shuttle driver screw① firmly.

D. Unfasten the shuttle (large) screw⑤. Turn the large hook control shaft⑥ left and right, then adjust the front/back

position of the shuttle (large)④ to set a clearance of 0.05~0.1mm between the needle and the shuttle hook point.

E. After adjusting the front/back position of the shuttle④, adjust the rotating direction of the shuttle④ to set a gap of

7.5mm between the needle and the shuttle④. Fasten the shuttle screw① tightly afterwards.

Loading...

Loading...