38

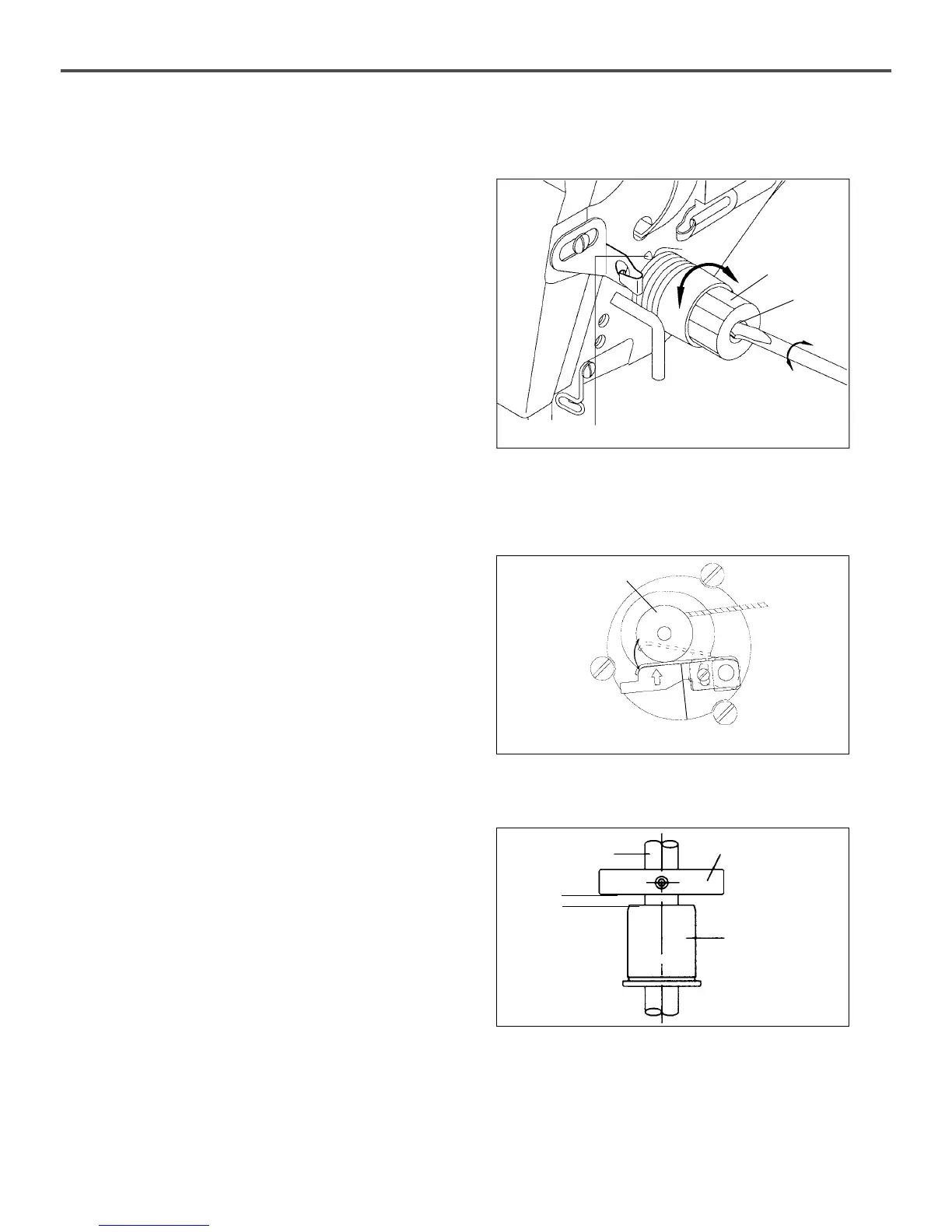

B. Set the thread winder driving wheel 4mm apart from

the upper shaft busing (front) and tighten the screw.

[Figure 79]

Bobbin Winder

Driving Wheel

Upper Shaft Busing

(Front)

Upper Shaft

4mm

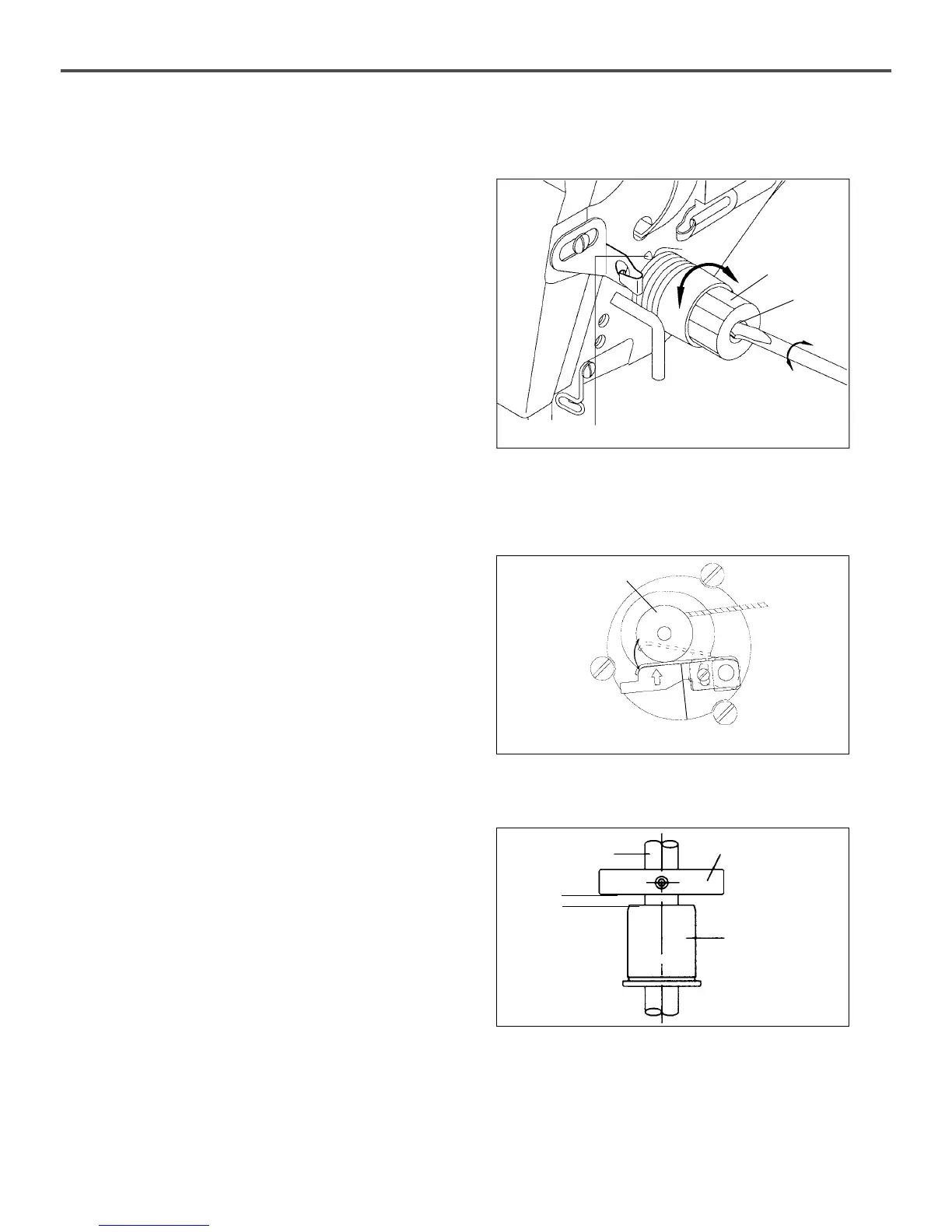

10) Adjustment of the bobbin winder

A. Use the starting (initial) position of the winder control

plate to adjust the winding capacity of the bobbin

winder. Unfasten the screw to turn the control plate in

the A direction for a large winding capacity, and turn it

in the B direction for a small winding capacity.

[Figure 78]

Bobbin Winder Control Plate

Bobbin

A

B

9) Adjustment of the main thread adjustment device

A. To increase tension of the upper thread, turn the nut①

of the thread control device in a clockwise direction,

and turn it counterclockwise to lower the tension.

Adjust the tension depending on various sewing

conditions, e.g., sewing materials, threads, number of

stitches, etc.

B. For controlling tension of the thread take-up lever

spring, use a driver to turn the groove on the edge of

the thread tension control device② clockwise for more

tension on the spring, and counterclockwise for less

tension on the spring. (Normally, it moves 6~8mm and

has tension of 30~50g)

[Figure 77]

①

Thread Take-up Spring

②

Loading...

Loading...