2.2.2 PERIODIC INSPECTION

(1) Inspection criteria

Check the motor at periodic intervals, referring to the following troubleshooting chart. If the

motor is used under a severe working condition, earlier or more frequent preventive maintenance

is required.

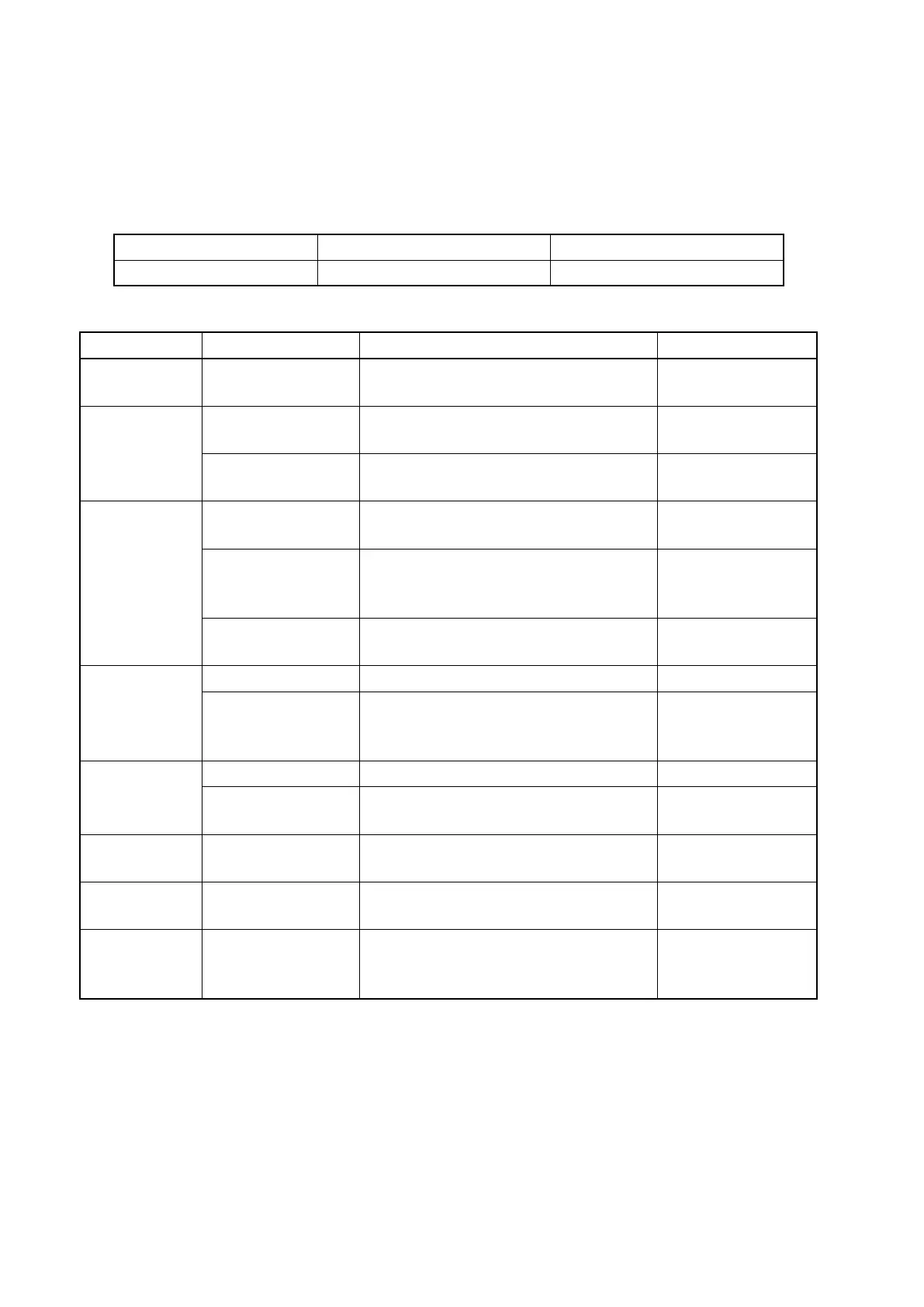

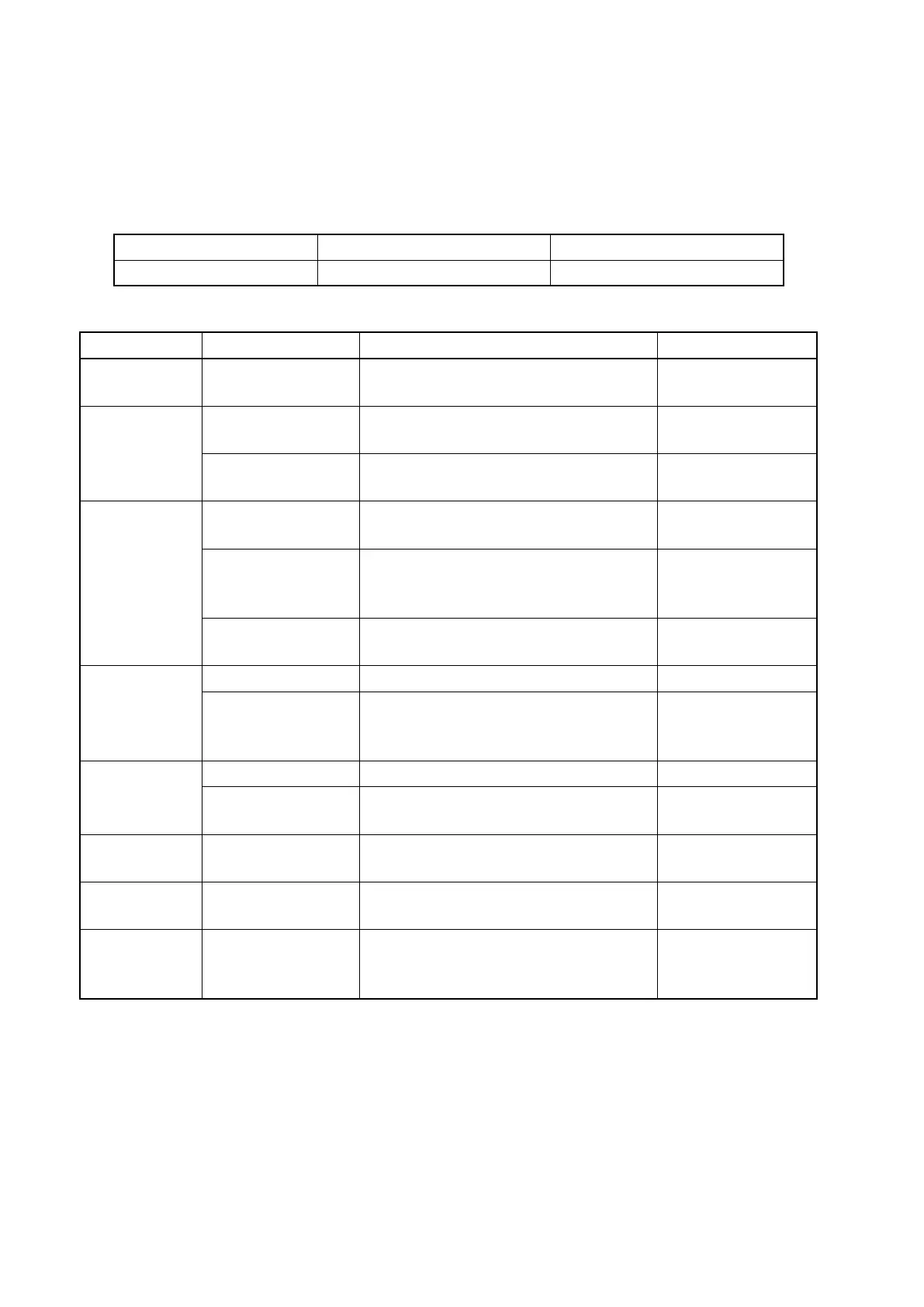

Operation time more than 12 hours/day 8 – 12 hours/day

Inspection interval Once a year Once every two years

Location Check item Criteria Remedy

Roller bearing Bearing (sealed type)

Check grease leaks, noise, adherence of

dust visually or audibly.

Replace.

Tightened areas

Joined parts

Check for damage or rough surface due

to corrosion visually.

Clean.

Fasteners

Check for looseness, corrosion or seizure

visually or by tapping.

Retighten, apply

anti-rust or replace.

Terminals

Joined areas

Check for damage or rough surface due

to corrosion visually.

Clean.

Connections

Visually check that connections are

correct and not loose, and that proper

insulation is ensured.

Retighten.

Lead wire Check coating for damage visually.

Ask specialist for

repair.

Stator and rotor

assembly

Iron core Check for adherence of dust visually. Clean.

Coil and insulation

at connections

Insulation resistance is more than 1 MΩ.

(Use 500 V megger)

Clean.

Heat.

Varnish.

Rotation sensor

Measure resistance 620 ± 60 Ω (20°C or 68°F) Replace.

Measure gap 0.7 ± 0.3 mm [0.028 ± 0.012 in.]

Ask specialist for

adjustment.

Thermo sensor Measure resistance 13.04 kΩ ± 10% (20°C or 68°F)

Ask specialist for

repair.

Painting Damage

Check for damage, discoloration, peeling,

or corrosion visually.

Apply anti-rust.

Paint again.

Cleanliness

Deposit of

contaminants or dust

Check for contamination, adherence of

dust or corrosion visually.

Clean or apply anti-

rust.

Paint.

Loading...

Loading...