10

www.tcsmeters.com

Total Control Systems

TCS 3000 Installation

Installaon Procedure — Grounding Strap

Installaon Procedure:

GROUNDING A TRUCK SEAT:

1. Idenfy any adjustable, shock absorbing seat in the truck cab.

These seats will typically have pivot points, hinges, or other me-

chanical design features that make seat adjustments possible.

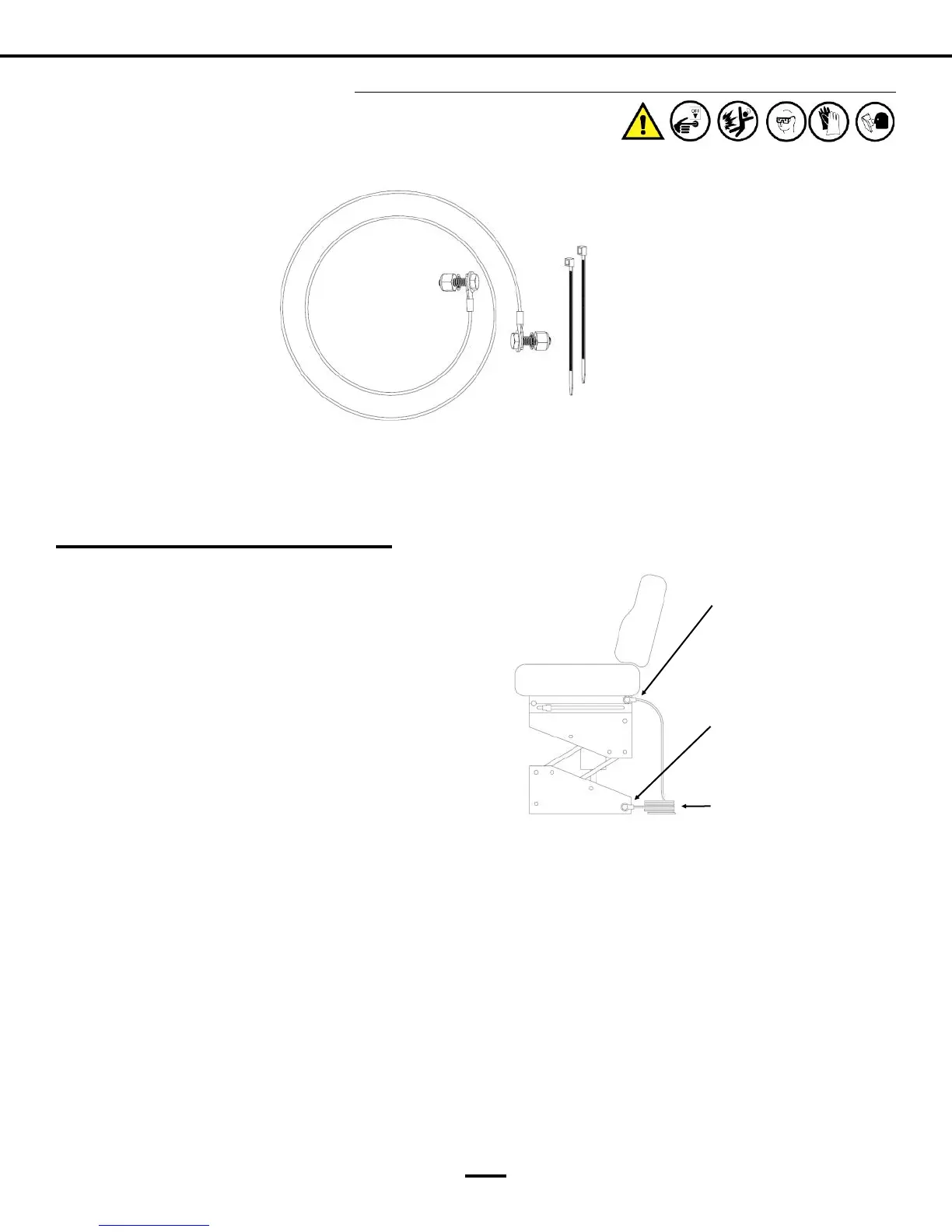

2. Find an exisng screw or hole near the back of the seat frame,

close to the cab oor. If a hole or screw does not already exist,

drill a 3/8” hole in the seat frame.

3. Aach one end of the ground strap to the seat frame bracket

using the lock washer, at washer and nut provided.

4. Find and exisng hole in the part of the seat frame aached to

the seat cushion above any pivots and adjustments. If a hole or

screw does not already exist, drill a 3/8” hole in the seat frame.

Make sure that there are no interfering pivots, guides, or adjust-

ment mechanisms that could interfere with the ground path

between the seat cushion and the ground strap. If the seat cush-

ion has a wooden base, aach the strap lug to an exisng screw

from the metal bracket directly aached to the wood seat where

the seat fabric is aached to the wood. There must be good

contact between the seat fabric and the ground strap lug.

5. Use the wire es provided with the kit and e o the strap so

that it doesn't interfere with the movement of the seat and is

clear of trac areas in the cab.

6. Check the strap for a good ground connecon. (see right)

Mount ground strap using sup-

plied hardware or an exisng

bolt. Do not use this ground

point if the seat cushion has a

front pivot.

Mount ground strap using sup-

plied hardware or an exisng

bolt.

Bundle excess ground wire using

a wire e.

Checking for good ground connecon along the ground strap:

1. Turn OFF all accessories, including the dome light, to prevent

other currents from distorng the reading.

2. Take a mulmeter and measure the resistance between the

brackets the ground strap bolts are fastened to.

3. If the resistance is less than 3Ω, the system is grounded ade-

quately. If the resistance is sll greater than 3Ω, check for

proper metal to metal contact on both ends of the grounding

strap. Clean any paint, dirt, or oxidaon that may block the

grounding point. If the resistance remains above 3Ω, aach

the ground strap to a dierent point and repeat the process

unl resistance is below 3Ω.

TCS 300597, Grounding Strap Kit

Zip Ties

#8 Grounding Strap

1/4” Hardware

Loading...

Loading...