Description 4

1-October-2013 United Kingdom Operations Manual

Page 4 - 4 TA9 & 10 Tier 4

4.5 Chassis

The two part chassis is of the centre pivot articulating type and is of a design which enables both

front and rear axles to be attached directly to the chassis members.

The front and rear frames are connected in the middle by a vertical pivot in spherical bearings

and a horizontal link, which connects between the spherical bearing of the vertical pivot and an

additional spherical bearing located in the rear frame.

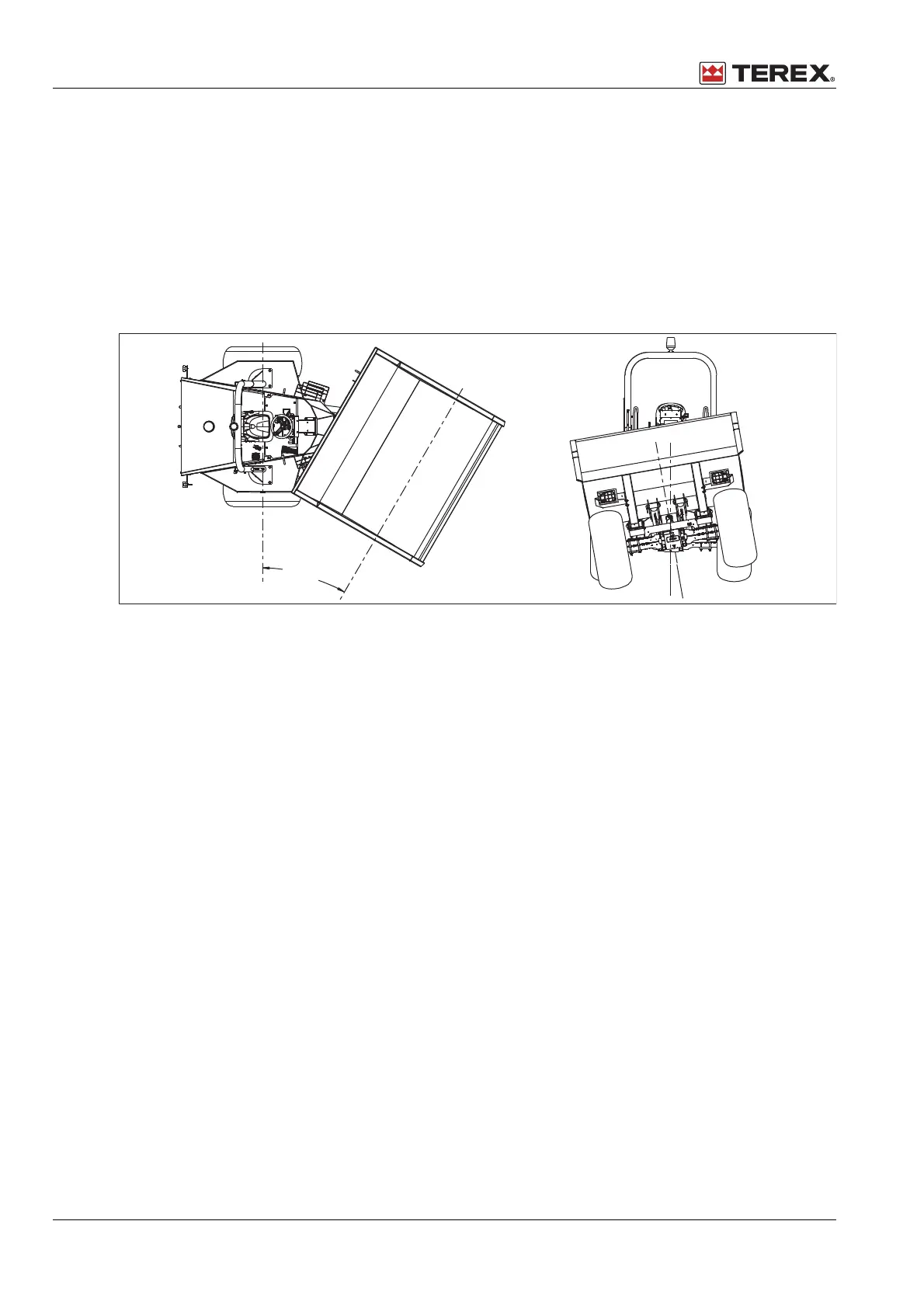

This arrangement is illustrated in Figure 4.3 and shows the articulation and oscillation of the

chassis

Figure 4.3. - Chassis Articulation Limits

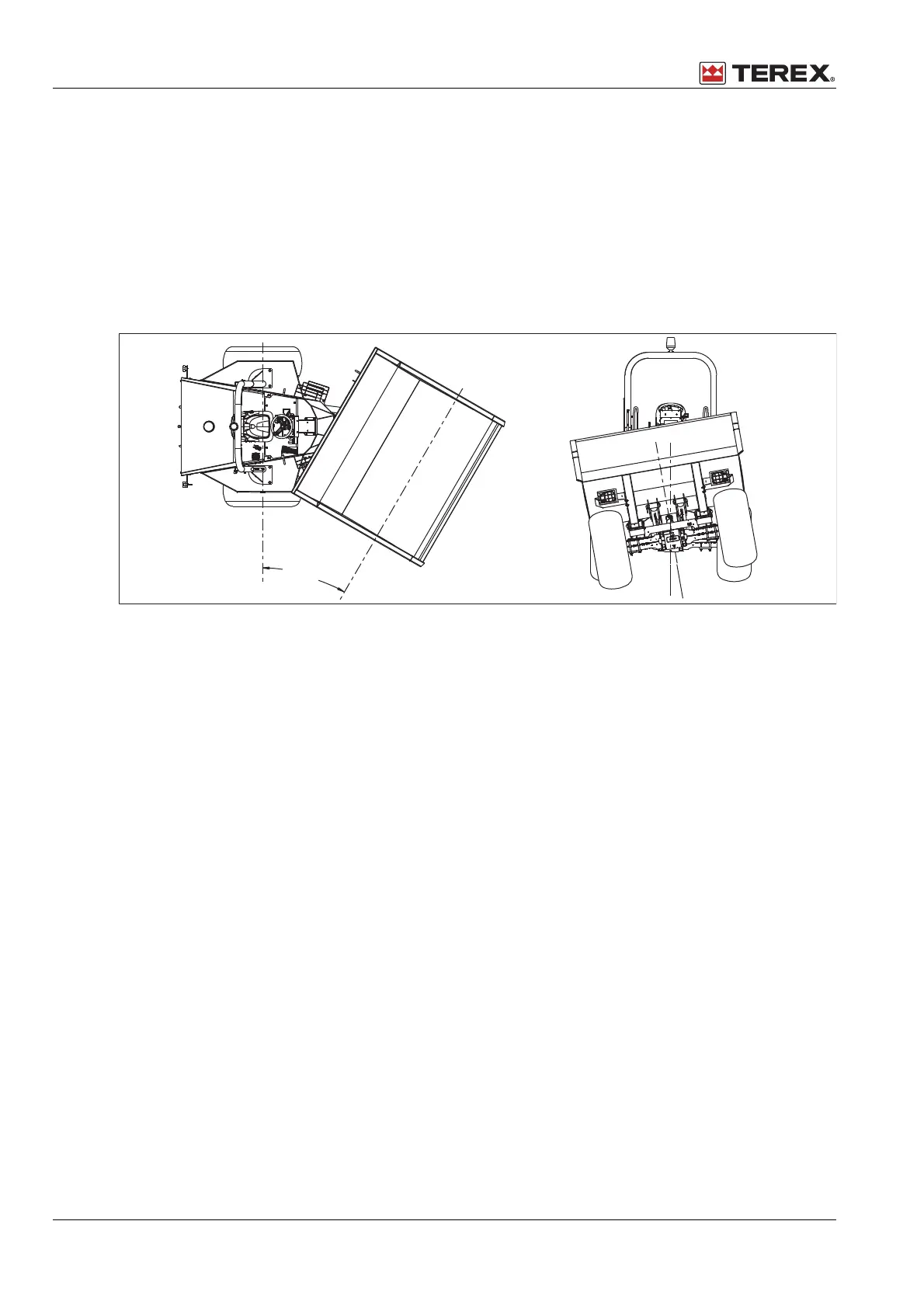

4.6 Hydraulic System

The hydraulic system provides power to operate the vehicle steering and to power the skip

elevation.

The system comprises an engine driven hydraulic pump drawing oil from a tank located inside

the chassis. The tank is fitted with a suction strainer, an oil level gauge, and a filler/breather cap.

The pressure is set at 172 bar (2495 psi) on TA9 machines and 210 bar (3045 psi) on TA10

machines The system is protected by a relief valve in the control valve that is set at the same

pressure.

A return line filter is fitted to the circuit and is of the replaceable cartridge type.

An oil cooler is fitted to reduce the temperature of the hydraulic oil.

Steering of the dumper is by means of a single hydraulic ram connecting the front and rear

frames, the oil supply to the ram is controlled by an “Orbitrol” hydrostatic steering unit.

The unit receives oil via a carry over port in the control valve and constantly meters oil to the

steering ram as the steering wheel is turned.

The control valve, operated by a lever next to the drivers seat, controls the tipping and lowering

of the dumper skip.

The skip can be elevated at varying speeds dependent on engine speed, and it can be stopped

at any intermediate point for discharging of partial loads.

Loading...

Loading...