Care and Maintenance 7

TC29

59

Grease all lubricating points with multi-purpose grease.

The intervals stated are valid for one-shift operation

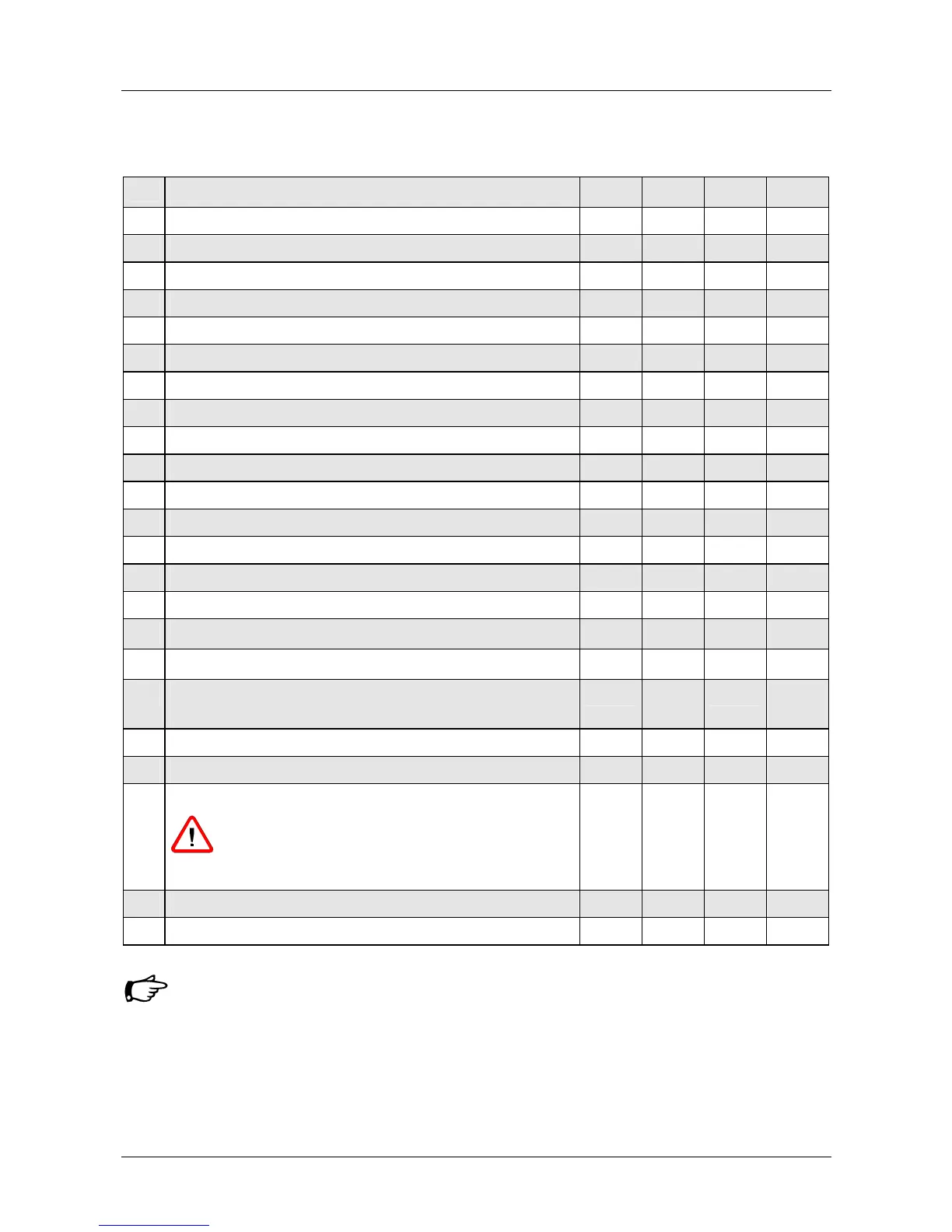

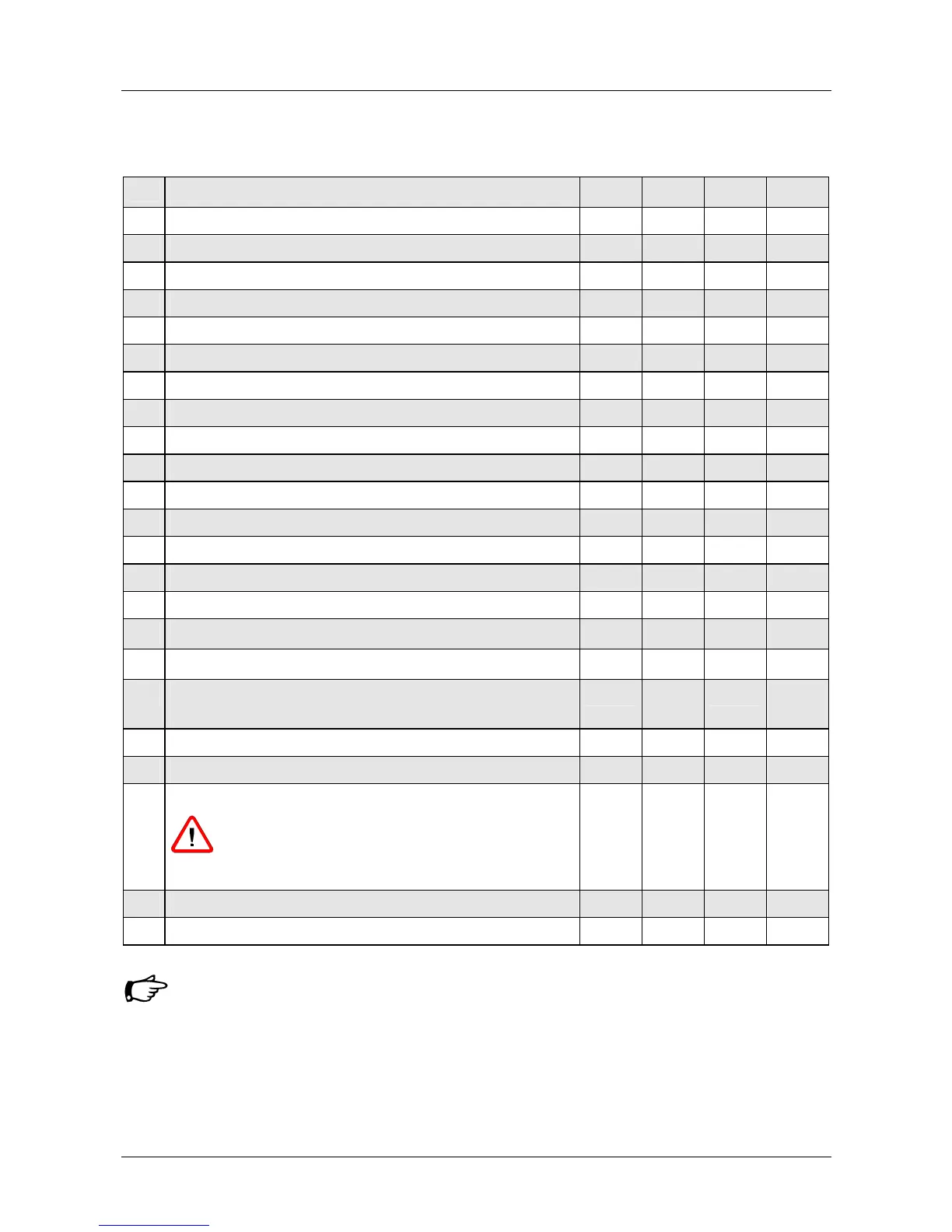

Item

Lubricating point

Qty. daily weekly Chapter

1 Bucket rod - Bucket (quick-mount hitch)

1 X --

2 Dipperstick - Bucket (quick-mount hitch)

1 X --

3 Bucket cylinder - bucket rod - tilt lever

3 X

--

4 Dipperstick - Tilt lever

1 X

--

5 Bucket cylinder - Dipperstick

1 X

--

6 Dipperstick cylinder - Dipperstick

1 X

--

7 Boom - Dipperstick

1 X

--

8 Dipperstick cylinder - Boom

1 X

--

9

Boom cylinder - Boom

1 X --

10 Boom cylinder - Slewing column

1 X

--

11 Slewing column - Boom

1 X

--

12 Articulated cylinder - Slewing column

1 X

--

13 Uppercarriage - Slewing column

2 X

--

14 Dozer blade cylinder

2 X

--

15 Dozer blade control lever

1

X

--

16

Ring gear - bearing system

2

X

7.9.15

17

Ring gear - toothing (open lateral lid, left-hand side)

1

X 7.9.15

18 Uppercarriage articulated cylinder

(open lateral lid, left-hand side)

1

X

--

19 Engine hood hinges

2

X --

20 Door hinges

4

X --

21 Quick-mount hitch

2

X --

For lubrication, place the bucket on the ground, open

the quick-mount hitch - the bolts must be fully

retracted - and start to lubricate. Close quick-mount

hitch.

Non-standard equipment

25

Clamshell grab 11

X --

We recommend that for special operations, e.g. on sandy ground, the lubrication intervals are

shortened. Increased frequency of lubrication helps self-cleaning of bearing points.

Loading...

Loading...