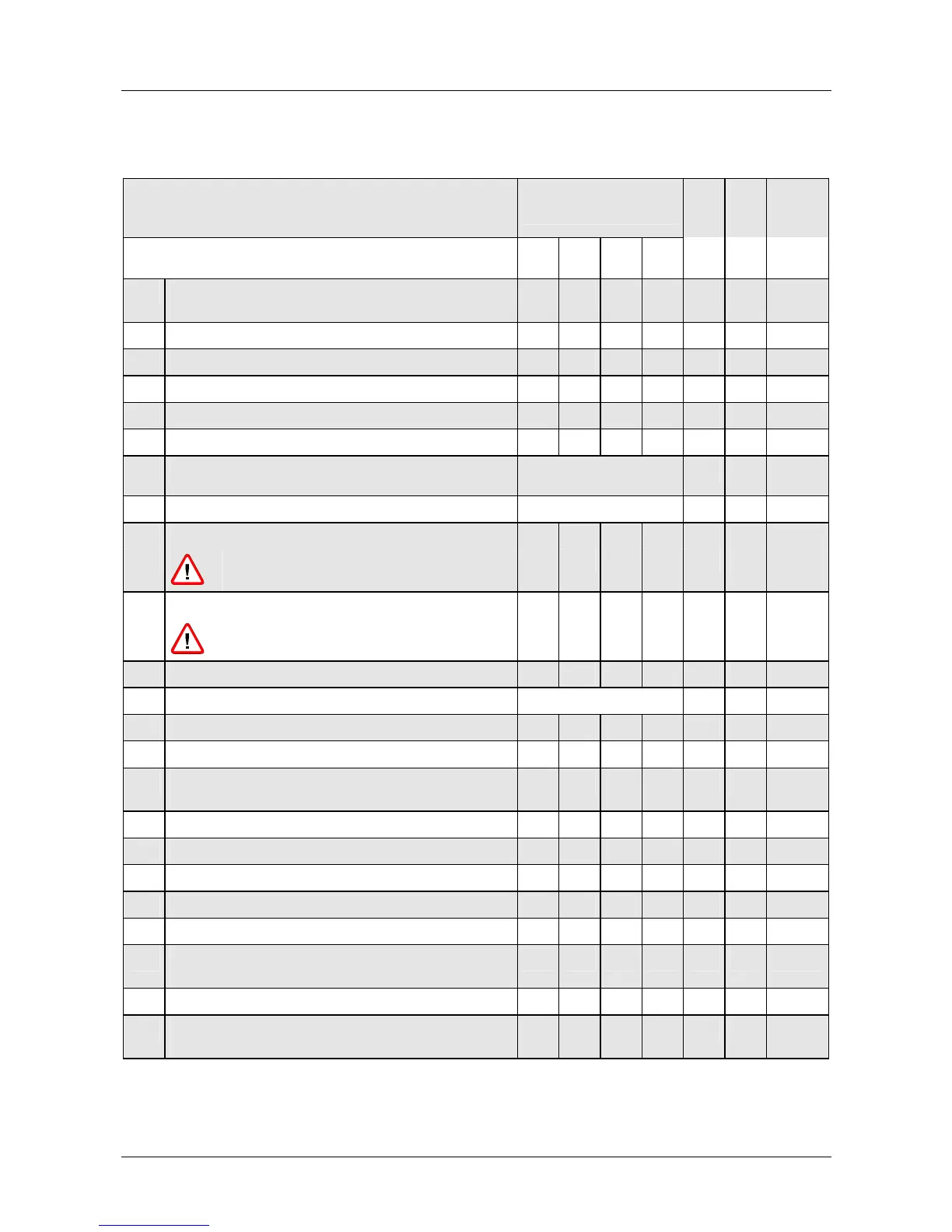

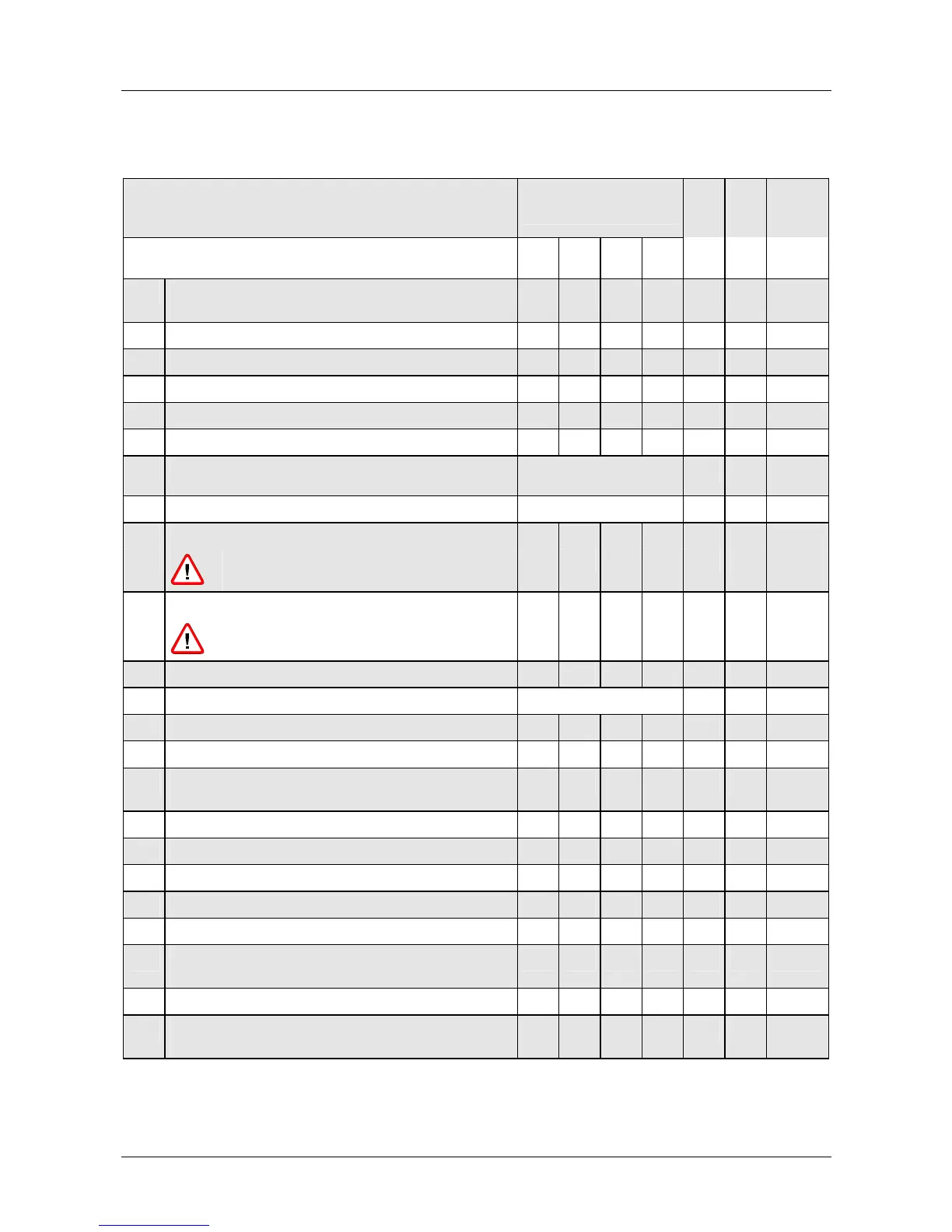

7 Care and Maintenance

TC29

60

7.8.4 Inspection plan

To be carried out by trained dealer personnel.

O = Checking, maintenance

X = Replacement

Operating hours

min.

2x

min.

1x

Perform work with machine at operating temperature

after

100

every

500

every

1,000

yearly yearly

Chapter

1 Check whether machine-specific instruction book is

in the machine

O O

--

2 Change engine oil

X X X

7.9.1

3 Change engine oil filter

X X X

7.9.2

4 Drain water from fuel tank

O O O

7.9.4

5 Change fuel filter

X X X

7.9.4

6 Check air intake

O O

7.9.5

7 Change air filter - main cartridge

in compliance with

service indicator

X

7.9.5

8 Change air filter - safety cartridge

as required

1)

7.9.5

9 Clean cooling fins of hydraulic oil cooler

O O O

7.9.9

The cleaning intervals should be shortened

if there is high exposure to dust

10 Clean cooling fins of water cooler

O O O

7.9.3

The cleaning intervals should be shortened

if there is high exposure to dust

11 Check antifreeze level in coolant

O

7.9.3

12 Change coolant

as required

1)

7.9.3

13 Check V-belt tension

O O

7.9.6

14 Check engine mounts and pump attachments

O O --

15 Check engine speed adjustment, top-end and low-

idle idle speed

O O --

16 Check valve lash of engine and adjust if necessary

O O O

7.9.7

17 Check injection nozzles

O

--

18 Check injection pump

O

--

19 Check acid level and battery connections

O O

7.9.18

20 Check condition of crawler chains

O O

7.9.14

21 Check secure fastening of sprocket, crawler gear

units and hydraulic motor

O O --

22 Check smooth running of bottom and top rollers

O O

23 Check bearing bushings and bolts of work

equipment and re-adjust "free of clearance"

O O --

Loading...

Loading...