Care and Maintenance 7

TC29

77

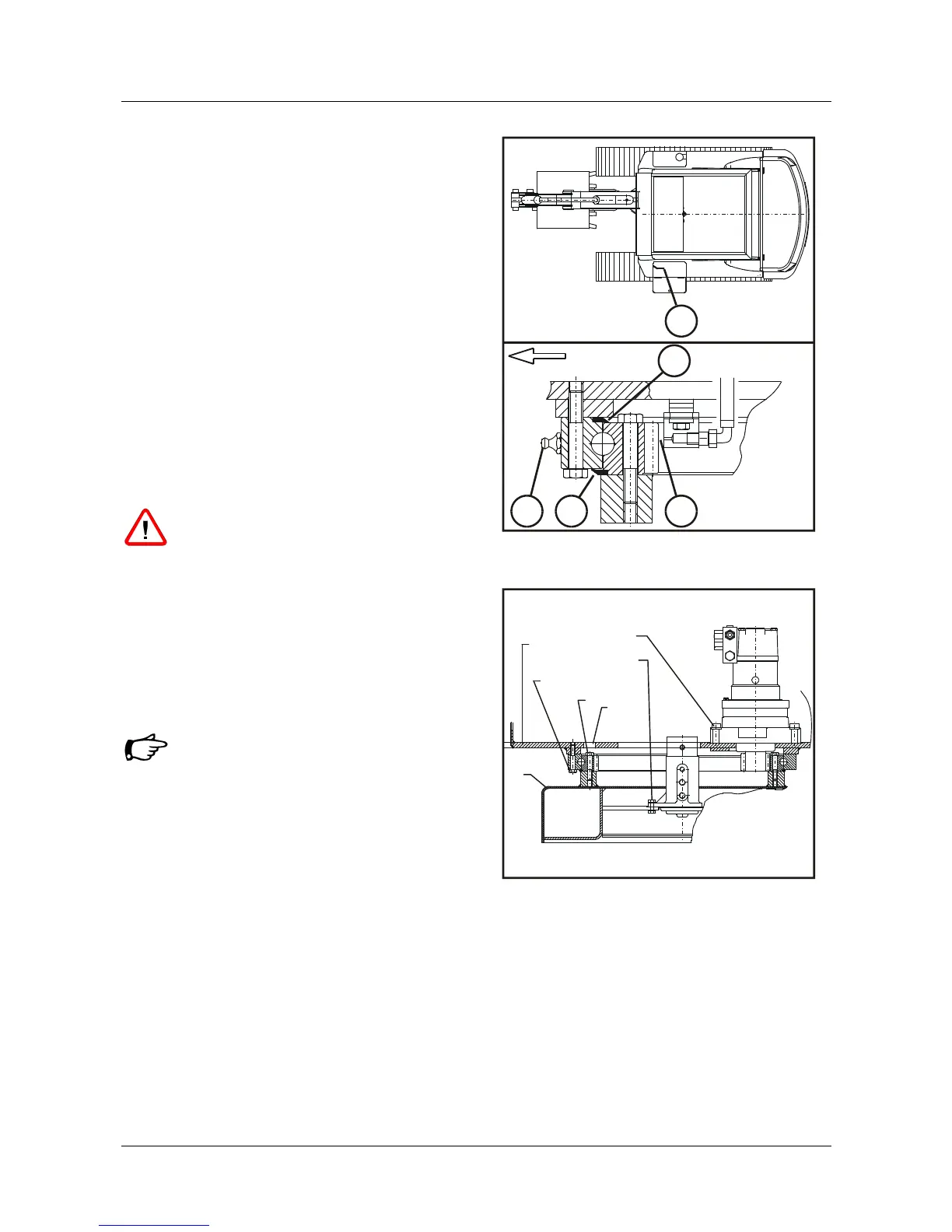

7.9.15 Swing bearing

Lubrication of toothing

• The grease nipple (66/1) mounted in the

driver’s cab lubricates the toothing of the ring

gear via a nozzle tube (66/2).

• To this purpose, slowly slew the uppercarriage

and lubricate it thoroughly at the same time

using a grease gun.

Lubrication of bearing races

• The bearing races are lubricated via the

lubricating nipples (66/3) mounted on the ring

gear.

• Slowly slew the uppercarriage, and lubricate it

thoroughly until the gasket has a collar (66/4)

of fresh grease.

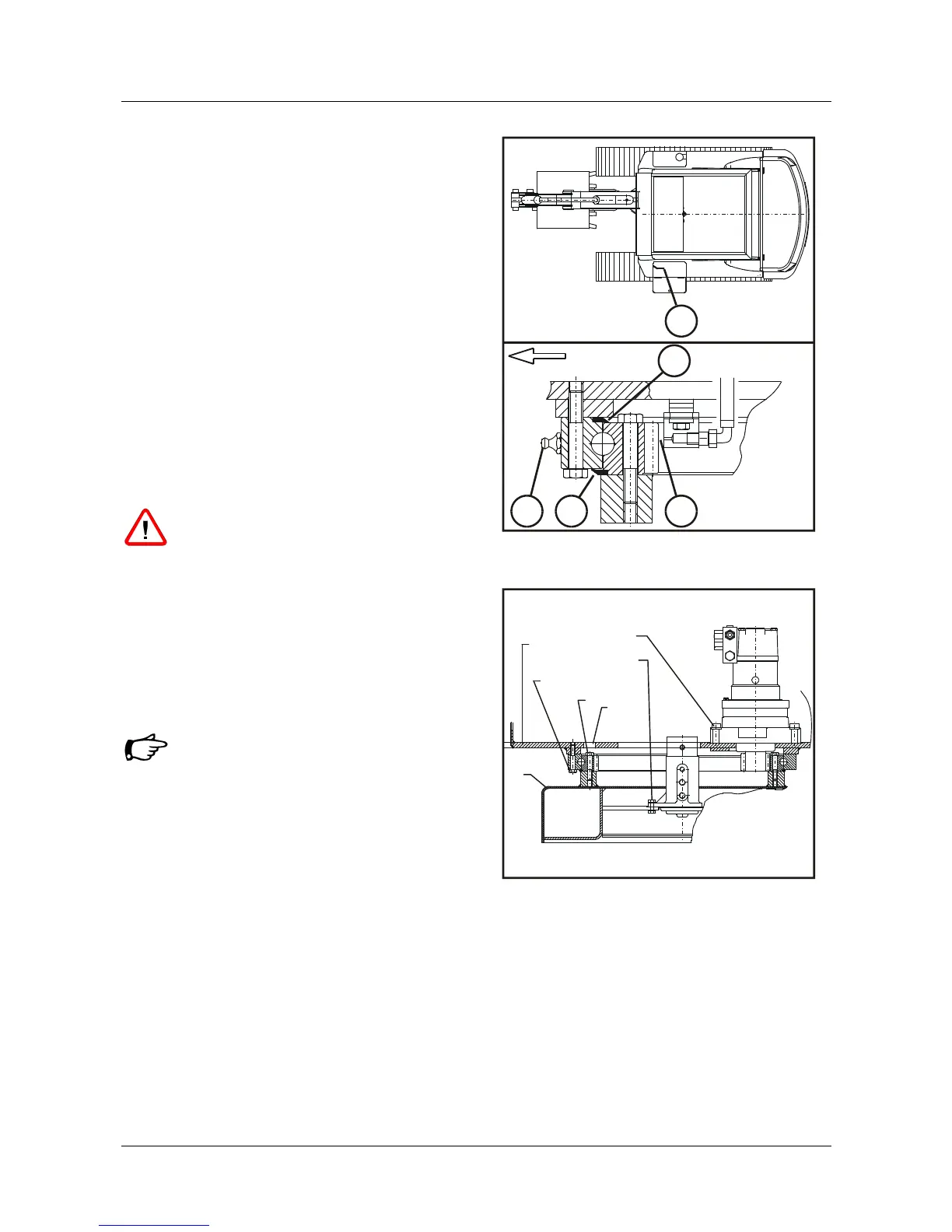

Check secure fastening of swing bearing

When mounting for the first time, the

screws must again be checked after 100

operating hours.

The following points are prerequisites for an

optimum bolted connection on the undercarriage

and the uppercarriage:

• The contact faces of bolts must be of bright

metal, i.e. absolutely free from grease and

paint.

• The thread and the bolt head shall not be

damaged.

Damaged screws must be replaced by

new ones!

All accessible screws must be examined to

ensure that they are tightened to the torques

specified in Figure 67.

Checking the swing gear attachment

All accessible screws must be examined to

ensure that they are tightened to the torques

specified in Figure 67.

A = uppercarriage

B = undercarriage

C = drill hole (x2) (below plastic plug)

HR14-03-66

4

243

1

Fig. 66-Ring gear

HR14-03-67

M = 115 Nm

A

M = 25 Nm

A

M = 290 Nm

A

M = 115 Nm

A

A

B

C

Fig. 67-Swing bearing

Loading...

Loading...