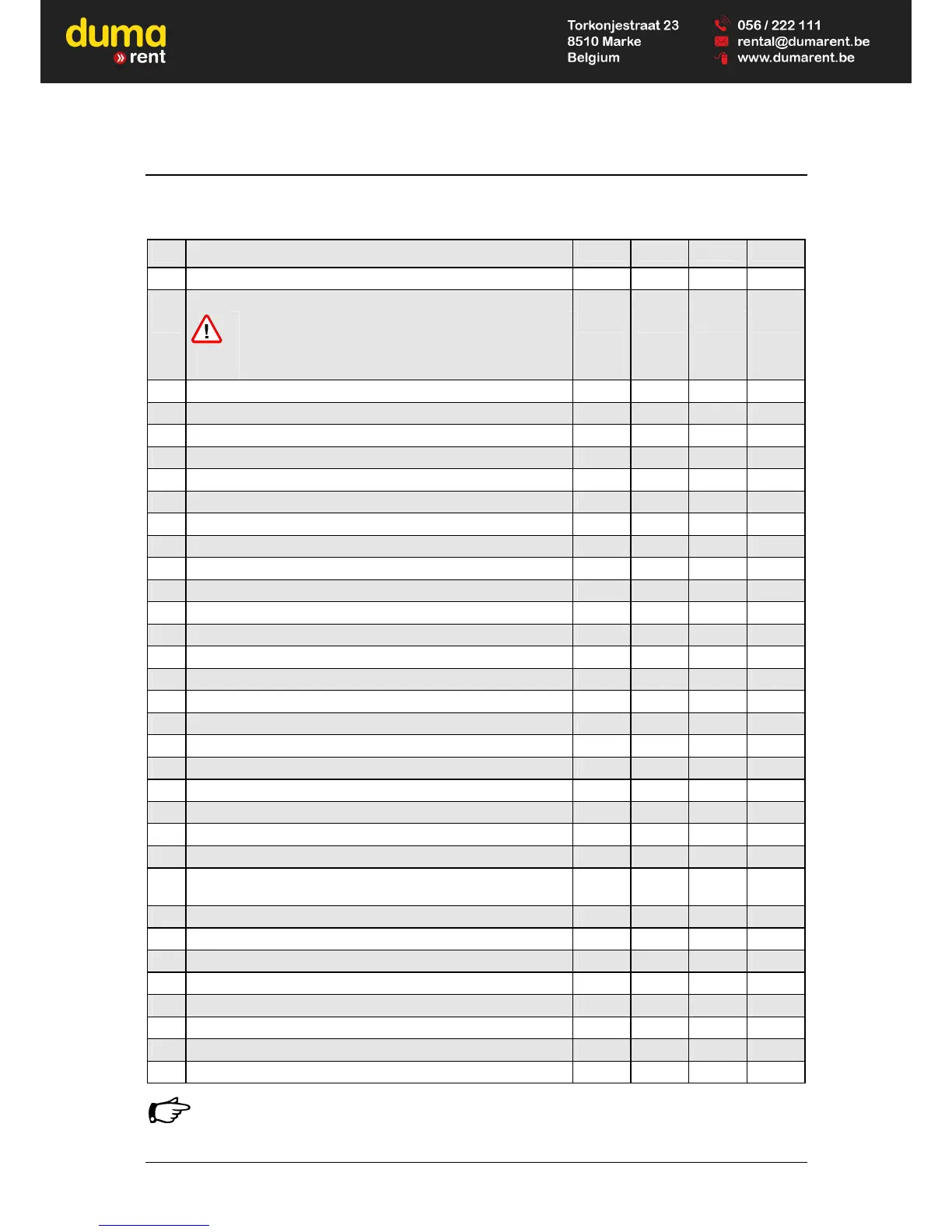

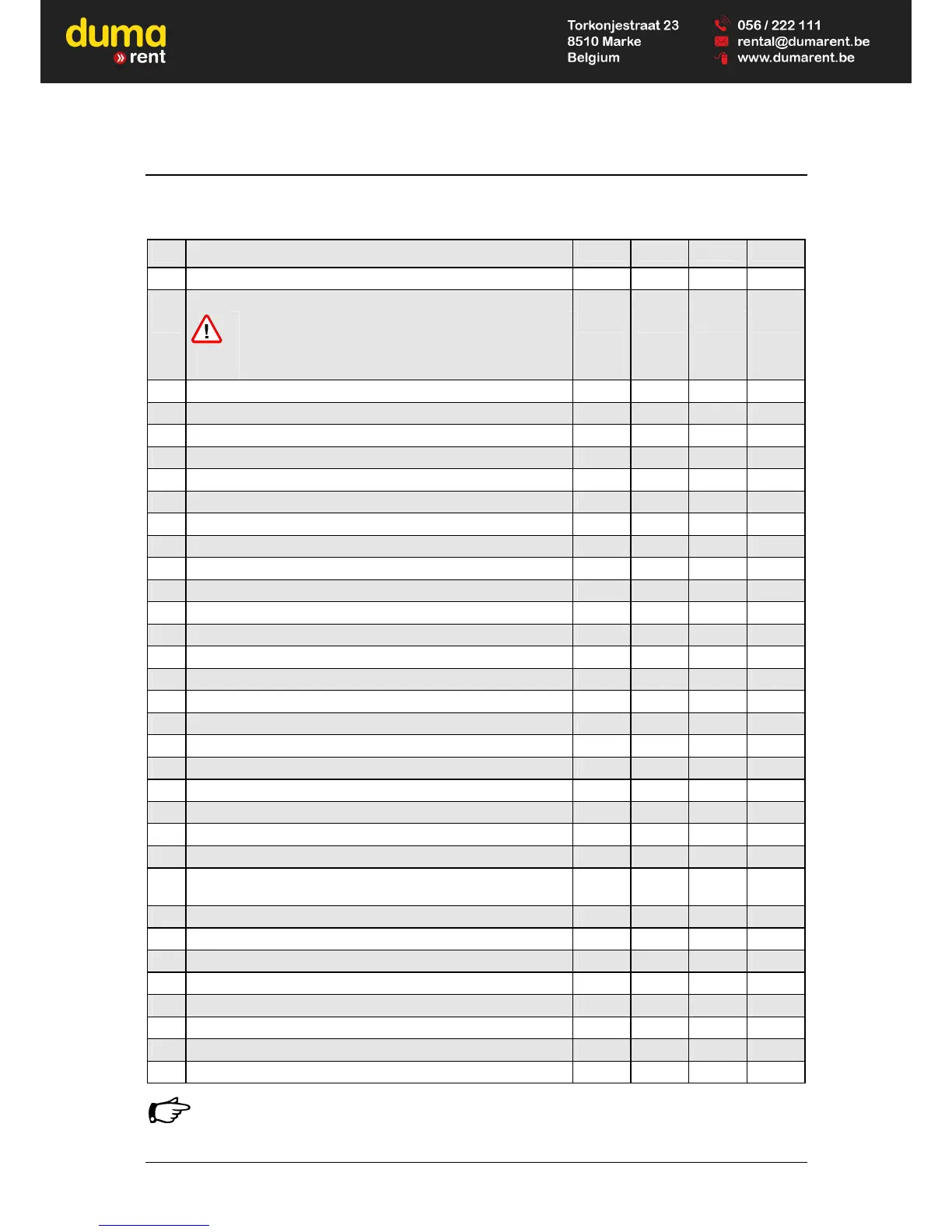

Maintenance and care 7

TW85 75

Grease all lubricating points with multi-purpose grease

The intervals stated are valid for one-shift operation

Item

Lubricating point

Number daily Weekly Chapter

1 Bucket rod – quick-attach system 1 X --

2 Quick-attach system 2 X --

For lubrication, place the bucket on the ground, open

the quick-attach system (the pins must be fully

retracted) - and start to lubricate.

Close the quick-attach system.

3 Bucket cylinder - Bucket rod - Tilt lever 3 X --

4 Dipperstick – quick-attach system 1 X --

5 Dipperstick - Tilt lever 1 X --

6 Bucket cylinder - Dipperstick 1 X --

7 Intermediate boom - Dipperstick 1 X --

8 Dipperstick cylinder - Dipperstick 1 X --

9 Intermediate boom cylinder - Intermediate boom 3 X --

10 Dipperstick cylinder - Intermediate boom 1 X --

11 Intermediate boom - boom 1 X --

12 Boom cylinder- Boom 1 X --

13 Intermediate boom cylinder - boom 3 X --

14 Slewing column - Boom 1 X --

15 Boom cylinder - Slewing column 1 X --

16 Boom - Dipperstick 1 X --

17 Dipperstick cylinder - Boom 1 X --

18 Uppercarriage - slewing column 2 X --

19 Support leg – Chassis 2 X --

20 Support cylinder – Chassis 2 X --

21 Support cylinder – support leg 2 X --

24 Pendulum bearing rear/front for front axle 2 X --

25 Ring gear - Bearing races 1 X 7.9.17

26 Ring gear - Toothing 1 X 7.9.17

27

Articulated cylinder – uppercarriage (center wall at slewing

column)

1 X --

28 Articulated cylinder - Slewing column 1 X --

29 Door hinges 2 X --

30 Steering housing each 2 X --

31 Door hinges for maintenance ladder 2 X --

Special equipment

34 Clamshell grab 11 X --

35 Swing bucket 2 X --

36 Hydraulic cylinders of swing bucket 2 X --

In the case of special operating conditions, e.g. working on sandy ground, the lubrication intervals

should be shortened, in order to encourage self-cleaning of bearing points.

Loading...

Loading...