Maintenance and care 7

TW85 93

7.9.11 Bleeding the plunger cylinders

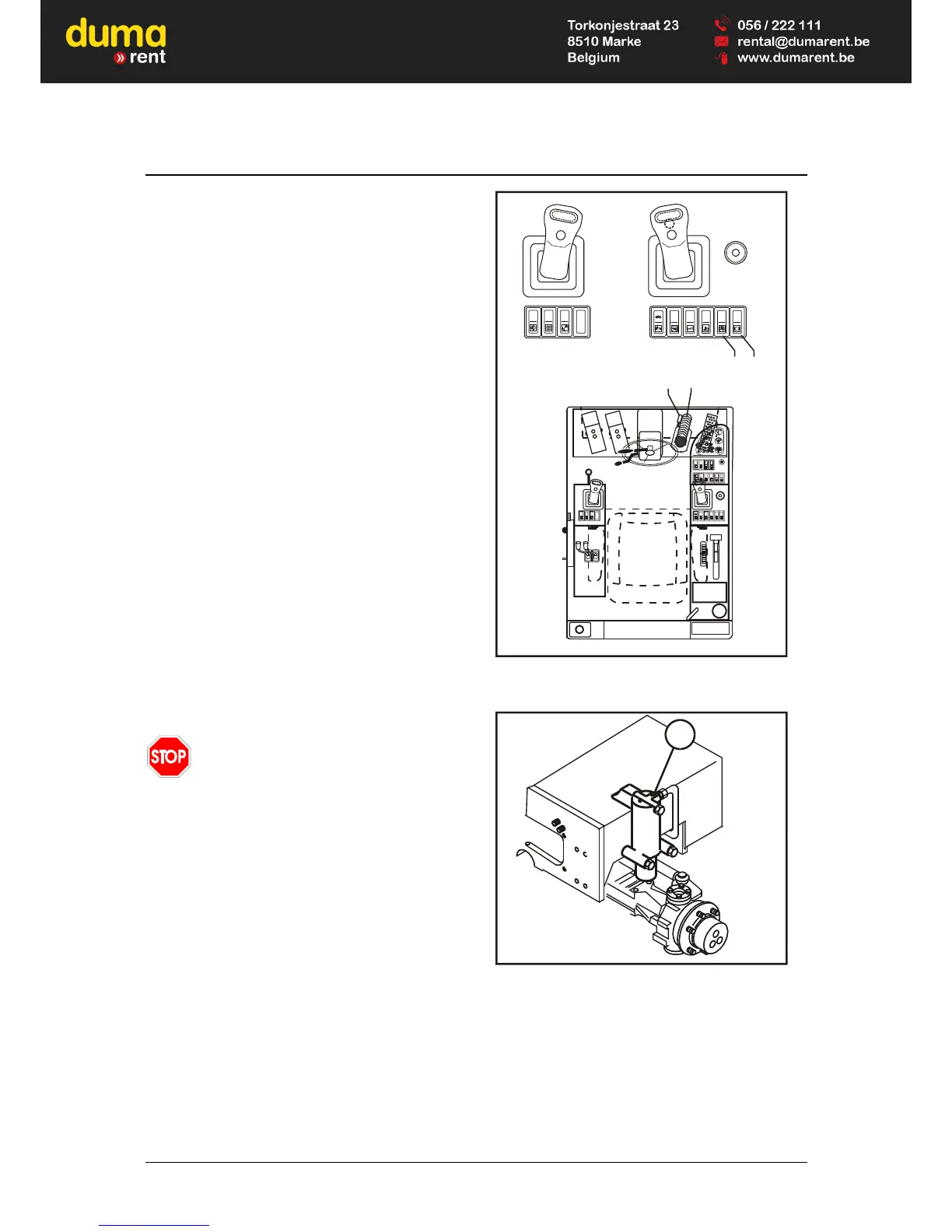

• Pressure supply is via the flushing oil circuit of

the hydrostatic drive.

• Latching occurs by blocking the connection line

between the plunger cylinders by means of

locking valve, which is activated by the

excavator brake (78/12) or the rocker switch

"pendulum axle locking" (78/62).

• The axle may not oscillate with excavator brake

engaged or toggle switch for pendulum axle

locking activated.

Bleeding

• Secure the machine against rolling away.

• Release excavator brake (78/11)

• Release the parking brake (78/63).

• Toggle switch for pendulum axle locking (78/62)

set to “OFF”.

• Let the engine run at medium speed.

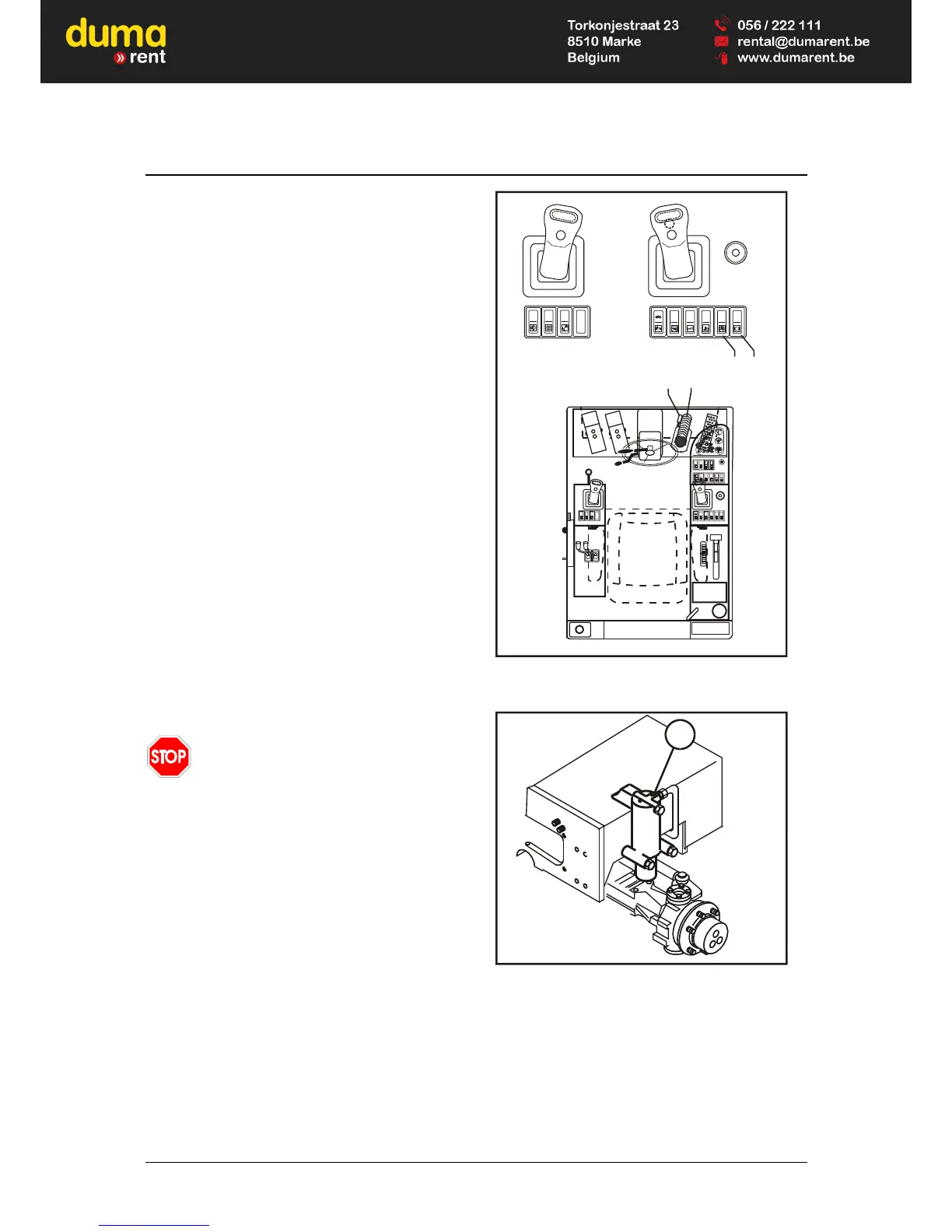

• Open bleeder screws (79/1) on plunger cylinder

right and left one after another until hydraulic oil

emerges without bubbles.

• Close bleeder screws.

7.9.12 Hose-rupture safety valves of support

legs

During this test, the machine must be

secured in such a way as to ensure that,

in the event of a defect in the hose-

rupture safety valves, there can be no

danger to persons or objects.

• Subject the outrigger to be tested to a load

applied in the non-operating direction.

• Switch off the engine; switch on the ignition.

• Operate the support leg’s control lever.

The function is correct when the controls do

not move the support leg!

P

HM32-078

62

63

11 12

Fig. 78 Operation

1

HM32-079

Fig. 79 Plunger cylinder

Loading...

Loading...