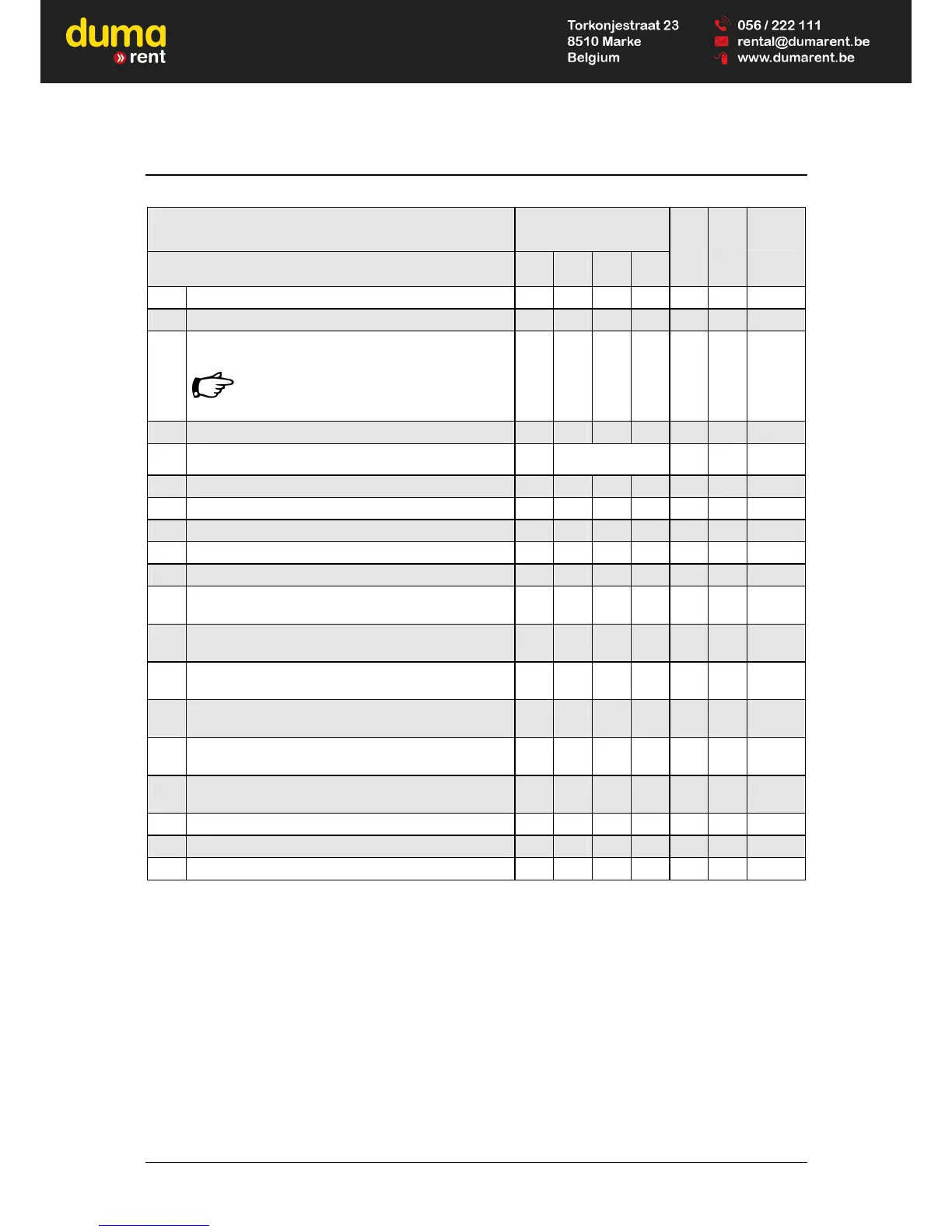

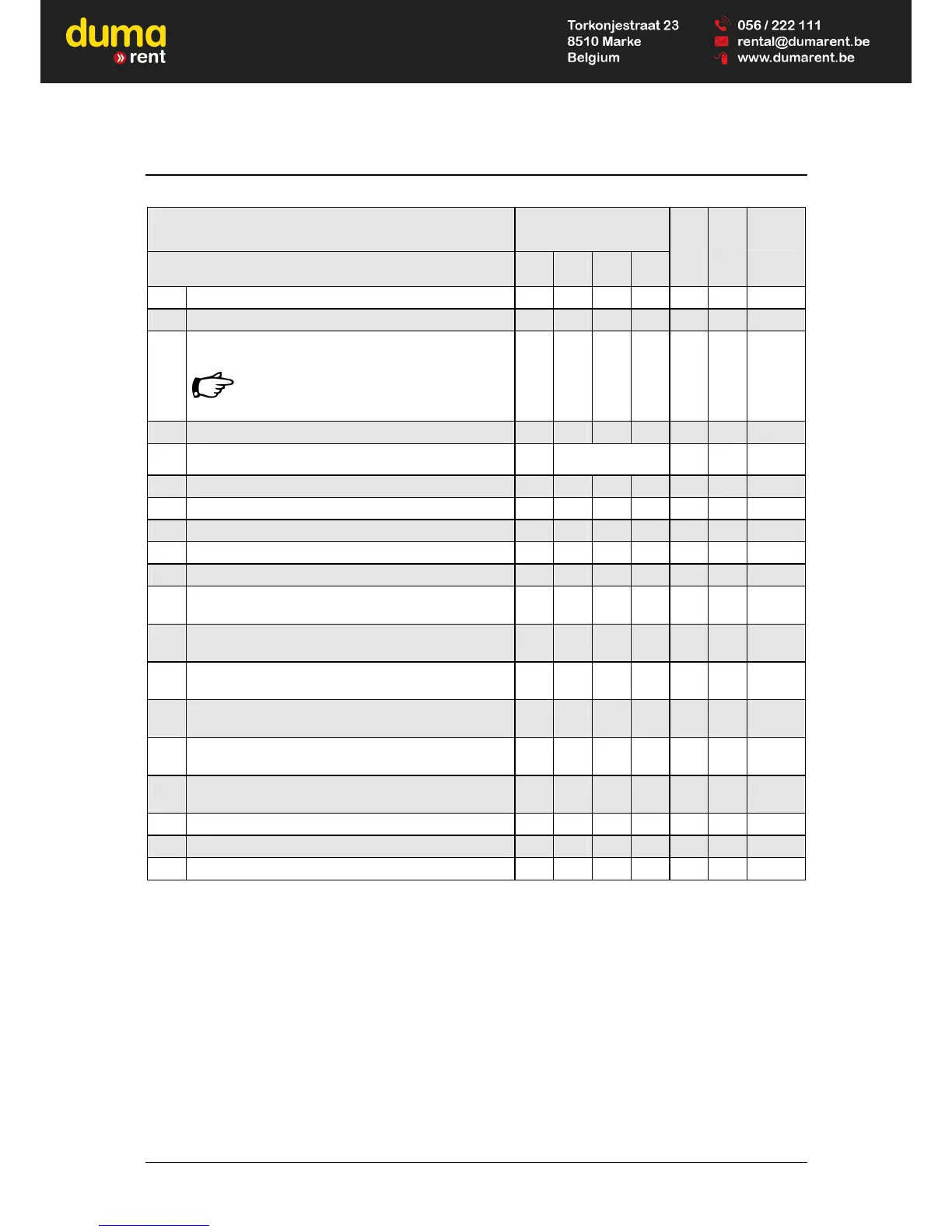

Maintenance and care 7

TW85 77

O = Checking, maintenance

X = Replace

Operating hours

min

2x

min

1x

Perform work with machine at operating temperature

after

100

every

500

every

1000

every

2000

year-

ly

year-

ly

Chapte

r

29 Check function and condition of supports

O O

--

30 Check hose-rupture safety valves of supports

O O

7.9.12

31

Check tightness of all pipes, hoses, control valves,

hydraulic pumps, cylinders, etc.

O O

--

When tightening hose and pipe connections,

screw-in couplings must be locked to

prevent rotation.

32 Check or change hydraulic oil

O O X

2)

7.9.7

33 Replace the hydraulic oil return filter insert.

X

according to the

service indicator

X

7.9.8

34 Replace the hydraulic oil suction filter insert

X X X

7.9.9

35 Replace the breather

X X

7.9.10

36 Check function of brakes and brake disc play

O O

7.9.14

37 Differential – rear axle oil: check or oil change resp.

X X X

7.9.13

38 Differential – front axle oil: check or oil change resp.

X X X

7.9.13

39

Transmission on front axle; check or oil change

resp.

X X X

7.9.13

40

Wheel hubs of front and rear axles; oil check or oil

change

X X X

7.9.13

41

Check that ring gear attachment screws are securely

fastened

O O

7.9.17

42

Check that swing-gear attachment (hydraulic motor

and transmission) is securely fastened

O O

7.9.17

43

Lubricate the machine according to overview of

lubricating points

O O

7.8.3

44

Check function, condition and completeness of

safety equipment

O O

--

45 Hydraulic function check with function pressure test

O O

--

46 Test run and test work

O O

--

47 Sign inspection card and return to manufacturer

O

O

3)

7.4

1) at least every 2 years

2) Extension of oil change intervals according to oil sample analysis and laboratory report

For further information see section 7.3.

3) under warranty

4) every 5 years or 5,000 running hours

Loading...

Loading...