CUTMASTER 60i

Manual 0-5475 SERVICE

5-17

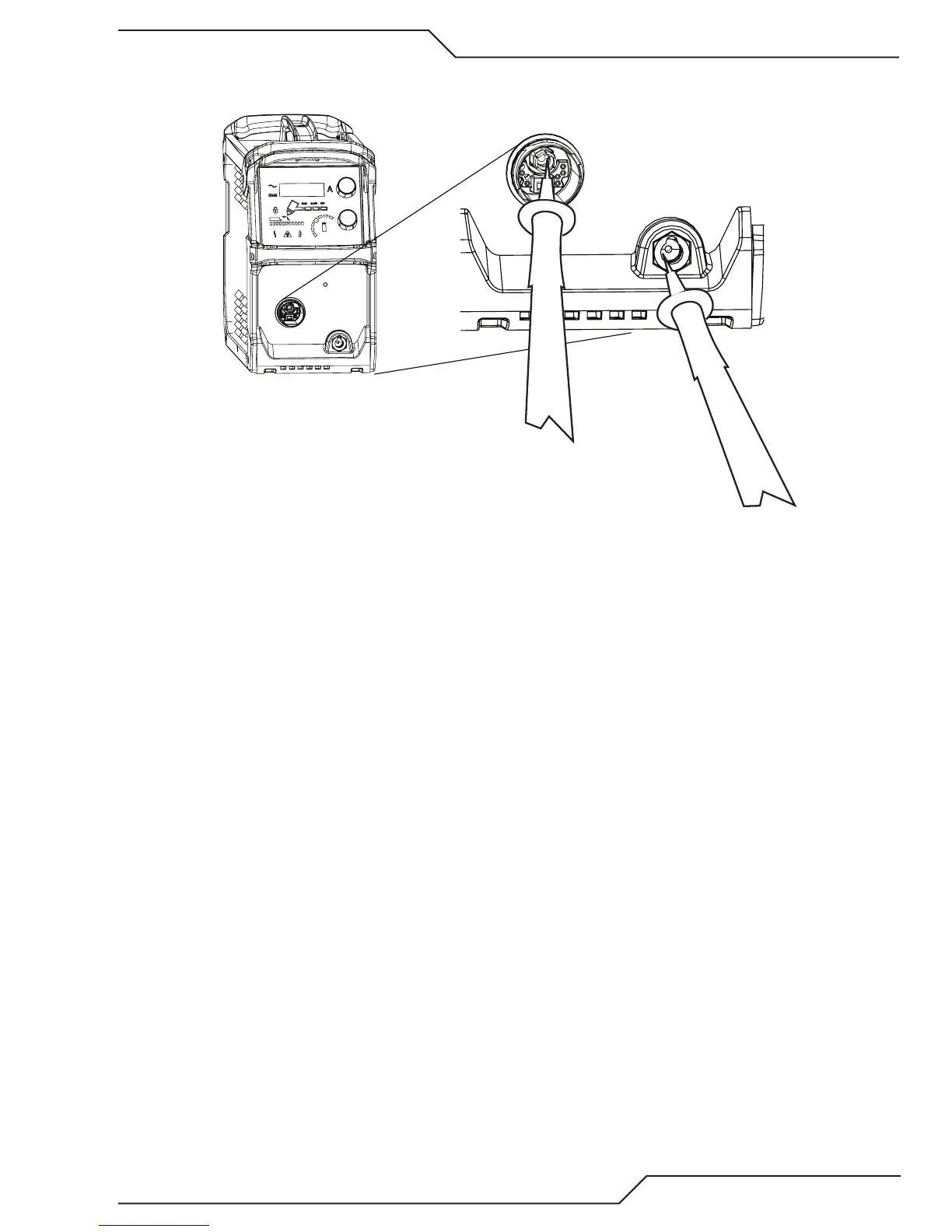

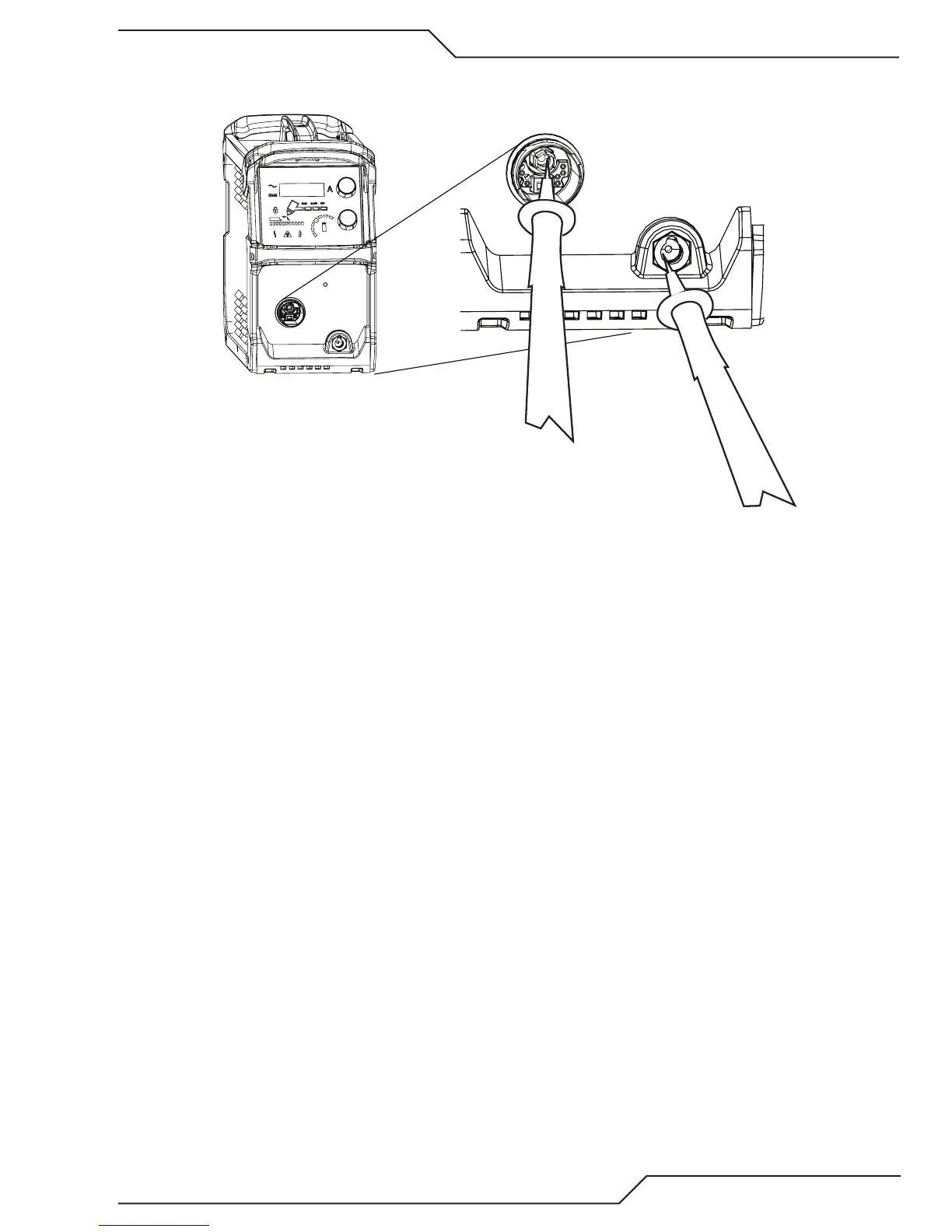

6. Inverter Board Output Diode Test. With the torch removed, measure Work to NEG at the front panel ATC

connector.

-

+

Art # A-13331

a. With meter on diode scale place the + lead on the negative terminal of the ATC connector and the – lead

on the Work lead Dinse receptacle.

b. The normal reading is that of a diode in the forward direction. (0.3V to 0.5V with Fluke.) If shorted replace

the Inverter board.

c. If above reads open, reverse the leads, you may have gotten + and – leads reversed.

d. If open in both directions check the connections from the work receptacle to the Inverter board stud la-

beled WORK. Also check for continuity from the ATC negative terminal to the SEC1 and SEC2 terminals

on the Inverter board. If these are OK replace the Inverter board

Loading...

Loading...