54

CARE AND MAINTENANCE

LOADING

GENERAL INFORMATION

1. Inspect the cargo box for proper insulation.

2. Ensure all door seals are tight seal with no air

leakage.

3. Inspect the cargo box inside and out for

damaged or loose doors or skin.

4. On the inside, look for damaged walls, air

ducts, floor channels or “T” flooring,

clogged defrost drain tubes and clogged or

damaged floor channels which could block

the air return, creating “Hot Spots” in the

load.

5. Pre-cool the cargo box as required.

6. Ensure loads are at proper carrying

temperature when you pick them up. Note

any variance.

7. Supervise loading of the product to assure

sufficient air space around and through the

load so as not to restrict air flow.

INSPECTING THE LOAD

Always inspect load prior to departure.

1. Ensure unit is off before opening cargo box

doors. Otherwise refrigerated air is expelled

hot air drawn in. The unit may be run with

the doors open if the truck is properly backed

into a refrigerated warehouse.

2. Perform final external and internal load

temperature checks. Note any irregularities

on the manifest.

3. Ensure cargo is not blocking the evaporator

inlets and outlets and that ample circulation

space has been provided around the load.

4. Ensure truck doors are securely locked.

5. Ensure controller setpoint is at the desired

temperature.

6. If the unit was stopped, restart using the

starting procedures outlined in this manual.

7. Repeat the After Start Inspection.

8. Defrost the unit one half-hour after loading

by selecting the Manual Defrost. The Defrost

cycle terminates automatically.

9. Carry out an on the road inspection every

four hours of operation.

Note: The unit will not defrost unless the

evaporator coil temperature is below 6°C.

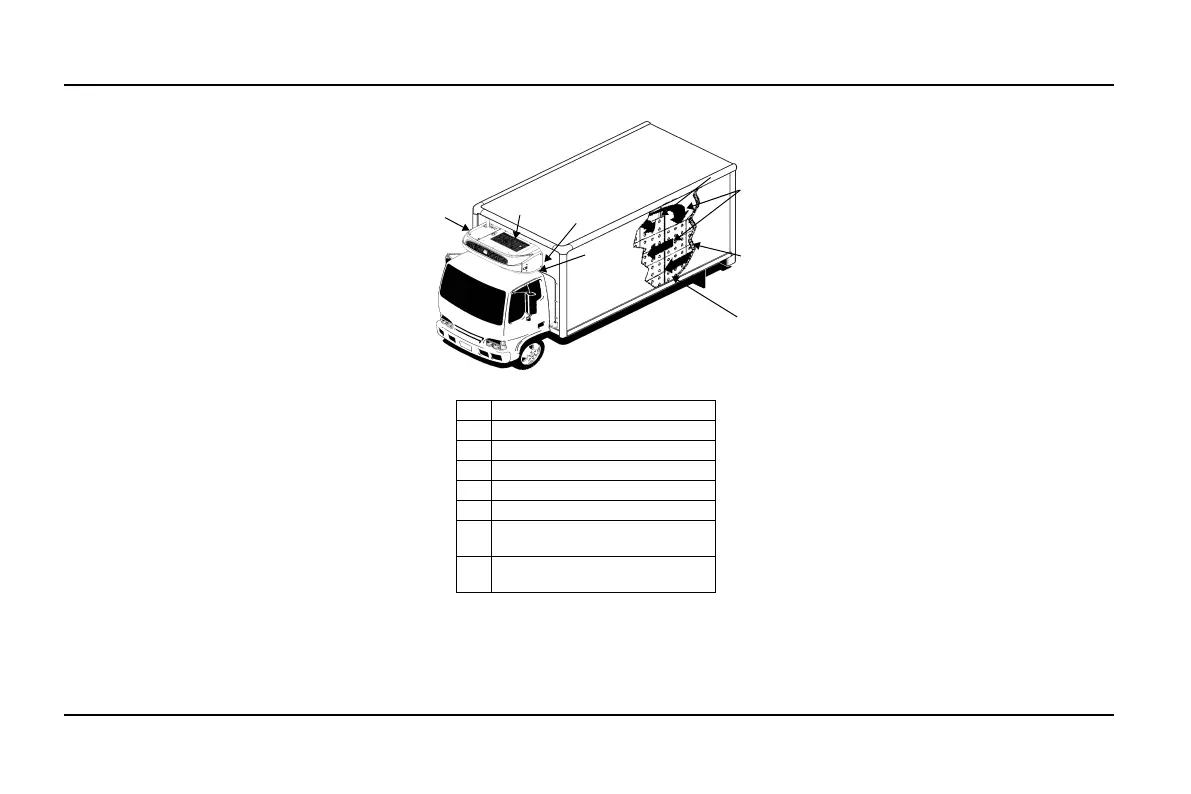

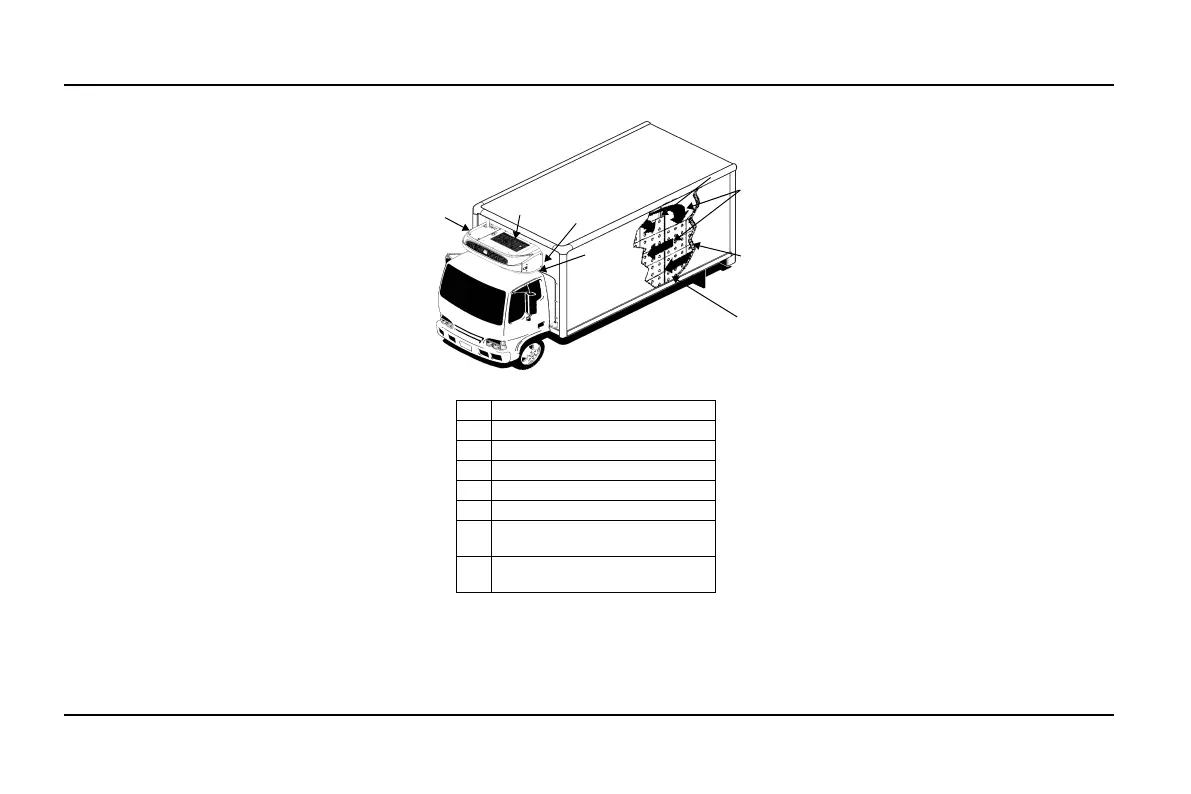

1. Unit inspection

2. Good outside air circulation

3. Seals equally compressed

4. Clear defrost drains

5. Tight doors

6. Good air circulation around load

7. Interior/exterior walls and

insulation in good condition

8. Cargo proper temperature prior

to loading

Loading...

Loading...