© Third Dimension Confidential Document D13-1604-GGUSER-EN-3.4

V7.6

33

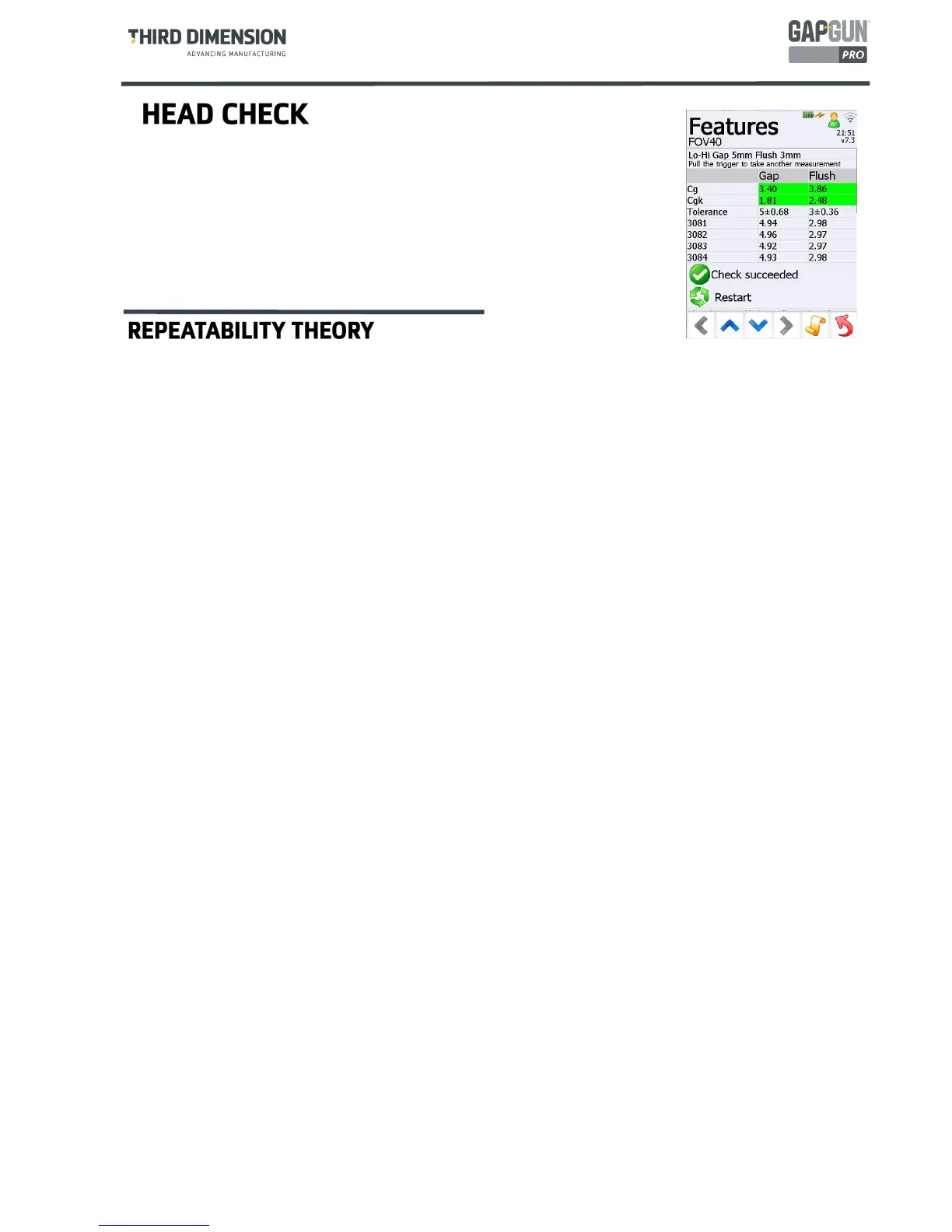

The Head Check function on the Context menu is an example of a statistical

checkplan. Instead of measuring the results then returning them to SPC3D, a

statistical checkplan measures the Feature multiple times and calculates the Cg and

Cgk values which indicate the repeatability of the measurement. These values are

useful when proving the tools are performing within tolerance as shown in the Head

Check function which confirms that the GapGun remains within calibration when

compared to the Gauge block.

Repeatability is a measure of the spread in the values of successive measurements of a characteristic and is usually

described in terms of a multiple of the standard deviation, σ, of the measured values. Industry standard gauge

capability uses Cg in order to specify repeatability, and Cgk to controls repeatability and bias.

A sequence of measurements (typically 25 or 50) using the same operator, in the same position on a known artefact

are taken and Cg and Cgk are calculated as:

Cg = (0.2 x T) / (6 x σ) and Cgk = ((0.2 x T / 2) – bias) / (3 x σ)

The minimum thresholds for acceptable repeatability are: Cg>=1.33 and Cgk>=1.33.

The formulae for Cg and Cgk are checking that the variation in the gauge is within 20% of the tolerance band being

controlled. Note, when calculating Cg and Cgk from a sequence of measurements, the numbers are only an estimate

of the true underlying Cg and Cgk values. The more measurements taken, the better the estimate will become.

Loading...

Loading...