Shenzhen Topwisdom Technology Co., Ltd

52

the corresponding icon changes from white to green. In the output test interface, press the

arrow keys to select the number, and press the select key to output the test. Press the enter

key to test all outputs with one key.

2. After finishing the testing Clock, SRAM and Flash, a dialog box will pop up to will

show the result.

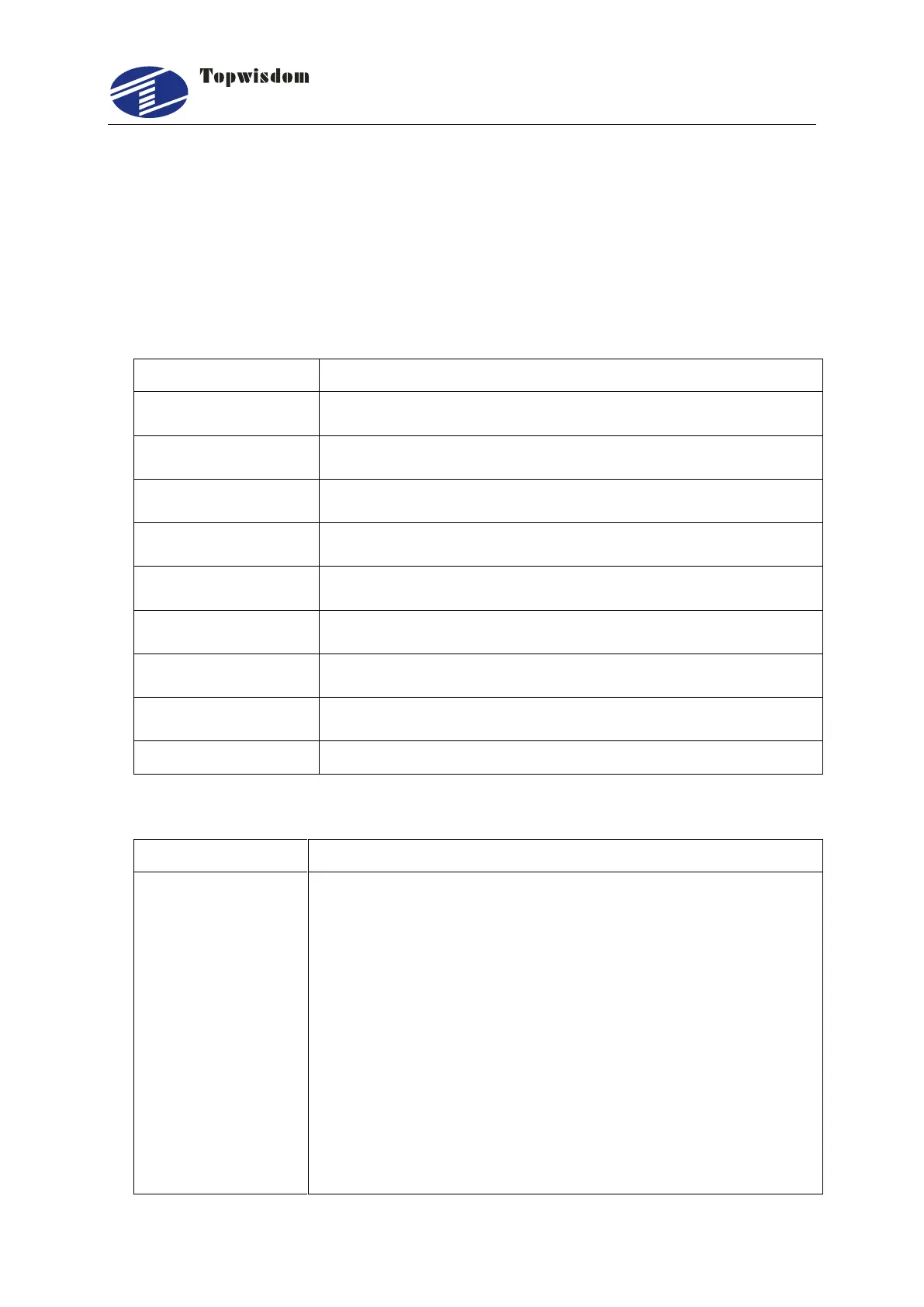

3. IO Input / Output Test Interface Description:

Input Test:

Lmt_X- X origin limit, axis movement to the minimum

coordinate (0) limit sensor input

Lmt_X+ X upper limit, axis movement to the max coordinate

limit sensor input

Lmt_Y- Y origin limit, axis movement to the minimum

coordinate (0) limit sensor input

Lmt_Y+ Y upper limit, axis movement to the max coordinate

limit sensor input

Lmt_Z/U- U origin limit, axis movement to the minimum

coordinate (0) limit sensor input sensor input

Lmt_Z/U+ Z/U upper limit, axis movement to the max

coordinate limit sensor input

Door_SW Protection signal input, connecting to cover

protection and other signals

Foot_SW Foot switch signal input, active on the rising edge,

with pulse width not less than 100ms

WP Water Cooling Protect Input, active at low level

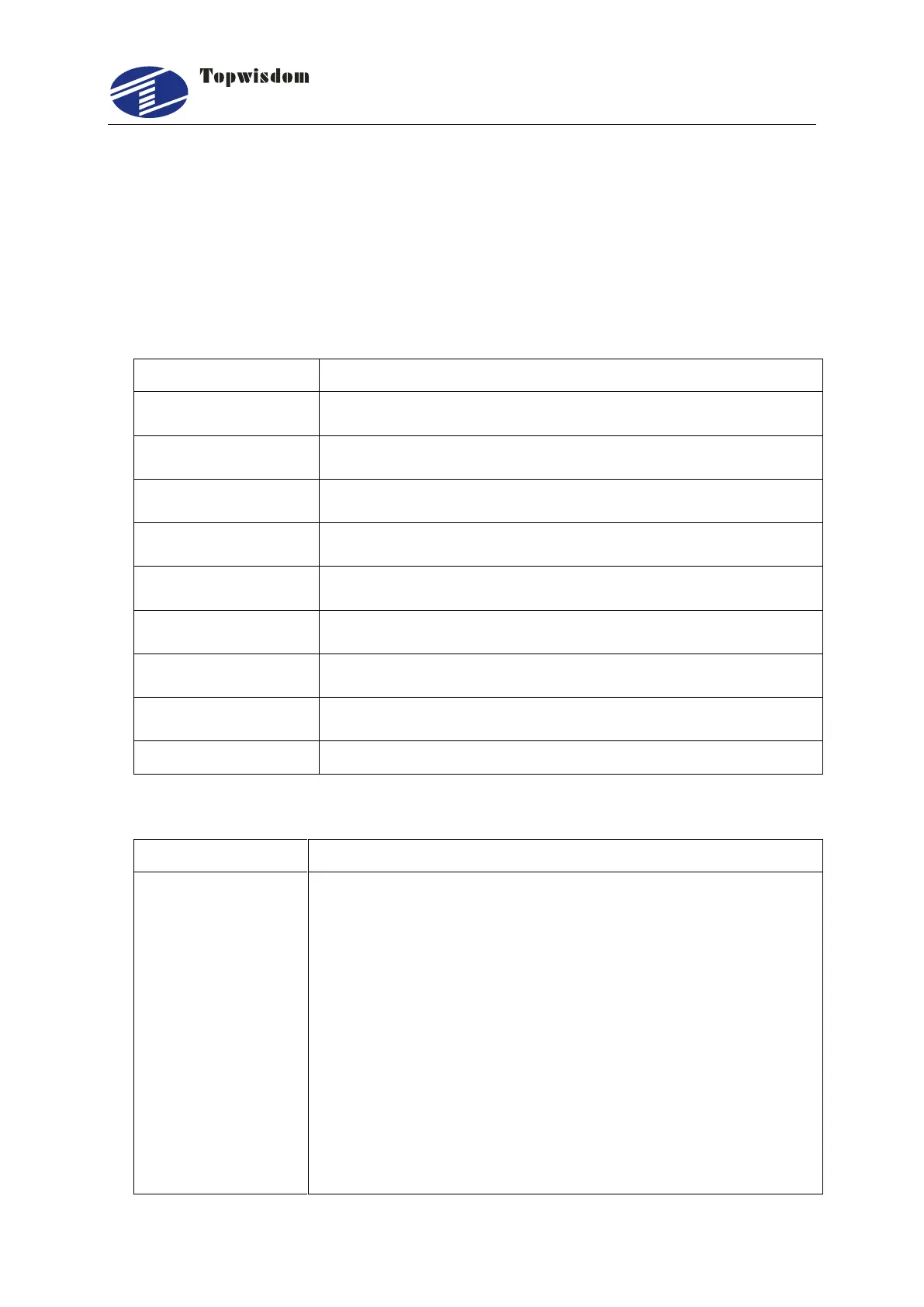

OUT1 A generic output signal that defines its function in

software:

Completion Work completion signal, output 300ms low pulse

width after the work is completed

Feeding Feeding signal, output when feeding, active at low

level

Laser Laser on signal,output when laser on

Press Feeding/pressing signal, synchronous pressing signal

at Y axis and U axis when feeding, active at low

level

Work Status Working status signal, output low level at work state,

output high level at standby or pause state

Pen Output low electrical level when dropping the pen,

output high electrical level when lifting the pen

Nip Rolls For rotary cutting head, used for control of press

Loading...

Loading...