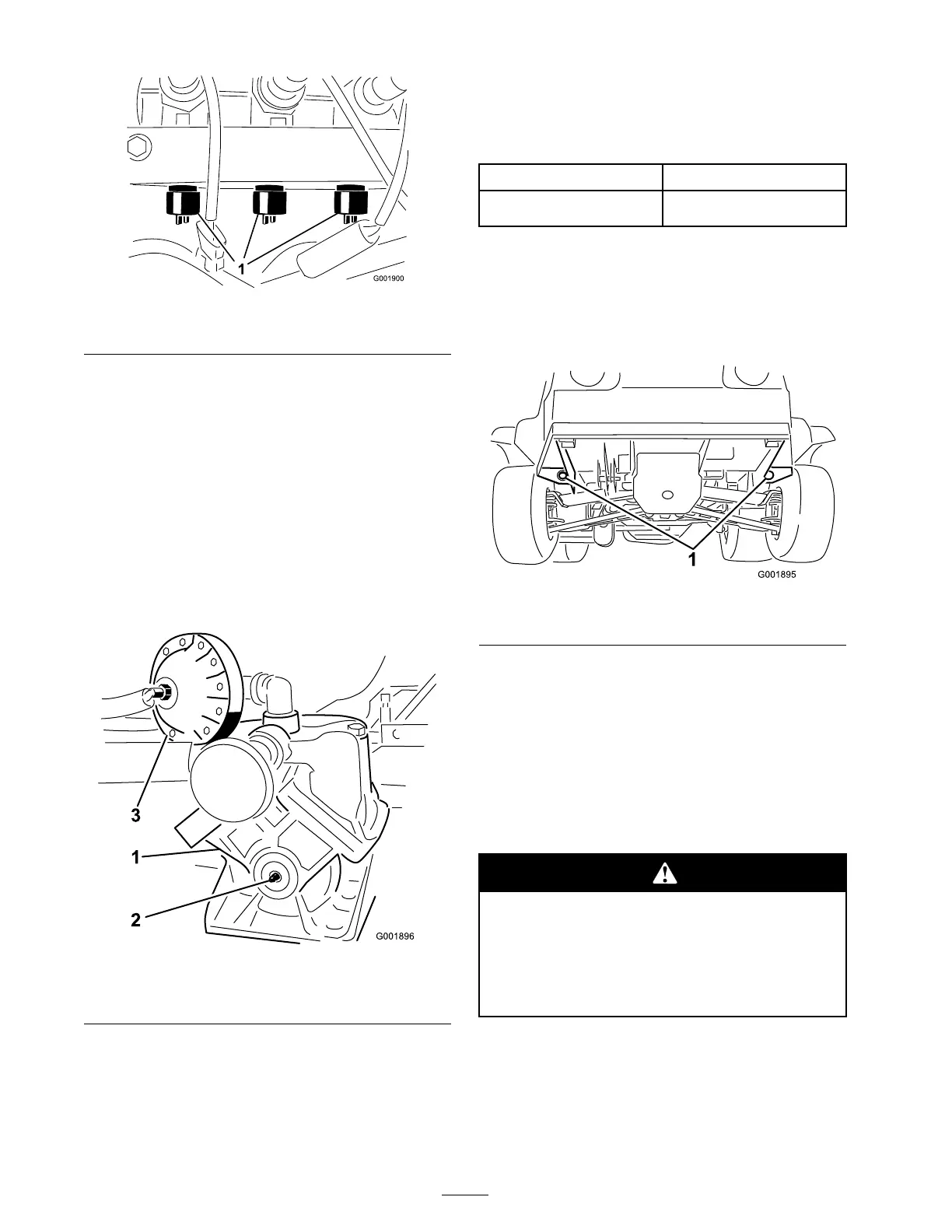

Figure 30

1. Boom bypass valves

13. T ur n the boom on and off to v erify the

pressure does not c hang e .

14. R e peat ste ps 11 through 13 for the other

booms .

15. Dri v e the spra yer at the desired speed while

spra ying and tur n eac h boom off indi vidually .

T he pressure on the g aug e should not c hang e .

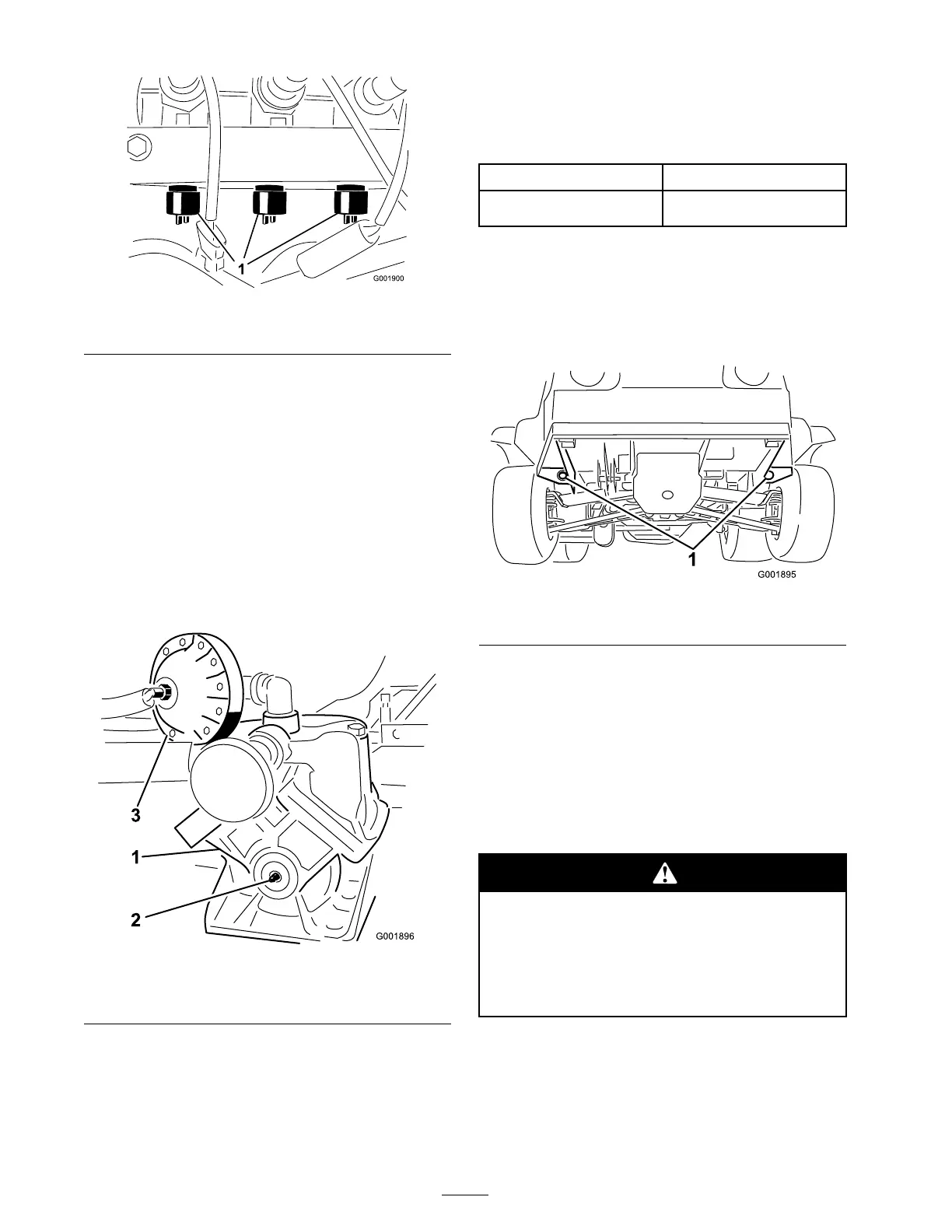

Pump

T he pump is located near the front of the tank on

the right side ( Figure 31 ).

Figure 31

1. Pump

3. Pressure dampener

2. Grease tting

Adjusting the Air Pressure in

Dampener

T he air pressure in the dampener on the pump is

set at 15 psi (1 bar) b y the man ufacturer . T his is

recommended for nozzle spra y pressures betw een

20 psi (1.3 bar) and 45 psi (3 bar). If different

nozzle pressures are required, set pressure

dampener at pressures indicated.

Nozzle

Dampener

40 psi/2.7 bar 12–14 psi/0.8–0.9 bar

Transporting the Sprayer

F or mo ving the spra yer long distances , use a

trailer . Secure the spra yer to the trailer . Figure 32

illustrates the front tie-do wn points .

Figure 32

1. Tie down points

T he rear tie-do wn points are tw o steel loops under

the bac k of the frame just in front of the adjustable

boom frame .

Towing the Sprayer

In case of an emerg ency , the spra yer can be

to w ed for a shor t distance . Ho w ev er , w e do not

recommend this as a standard procedure .

T o wing at ex cessi v e speeds could cause a

loss of steering contr ol, r esulting in per sonal

injur y .

Nev er to w the spray er f aster than 5 mph

(8 kph).

T o wing the spra yer is a tw o person job . If

the mac hine m ust be mo v ed a considerable

distance , transpor t it on a tr uc k or trailer; refer to

T ranspor ting the Spra yer .

1. Affix a to w line to the frame .

36

Loading...

Loading...