DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

1.Preparethemachineformaintenancereferto

PreparingtheMachineforMaintenance(page

65).

2.Checktoensurethattheairpressureinalltires

is83kPa(12psi).Checkthetireswhentheyare

coldtogetthemostaccuratepressurereading.

Important:Uneventirepressurecancause

unevencoringdepth.

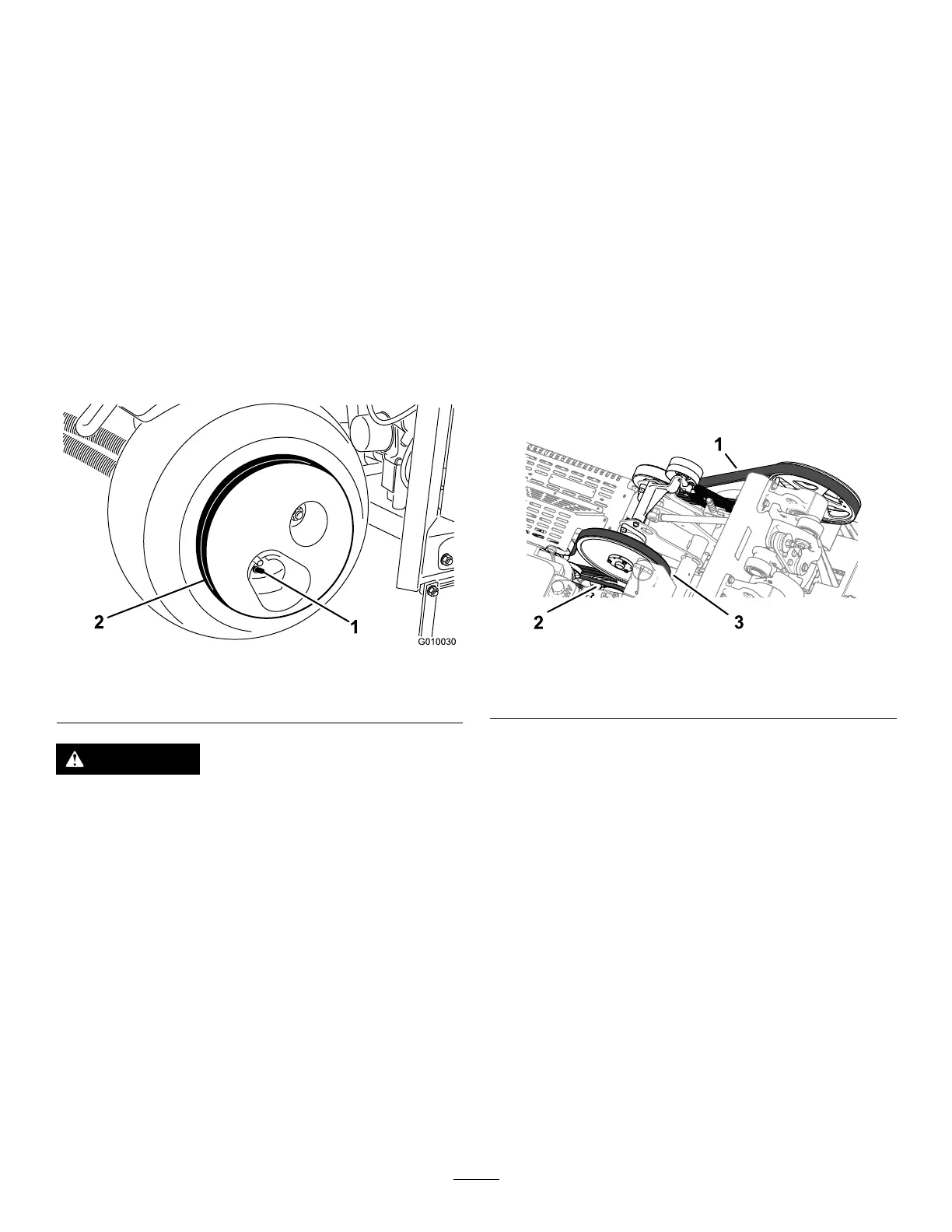

g010030

Figure173

1.Valvestem2.Wheelweight

CAUTION

Thewheelweightisveryheavy,33kg(73lb).

Usecautionwhenremovingitfromthetire

assembly.

BeltMaintenance

InspectingtheBelts

ServiceInterval:Yearly

Thedrivebeltsofthemachinearedurable.However,

thenormalexposuretoUVradiation,ozone,or

incidentalexposuretochemicalscandeteriorate

therubberovertimeandleadtoprematurewearor

materialloss(i.e.,separatedormissingbeltplies).

1.Removethebeltcover;refertoRemovingthe

BeltCover(page66).

2.Inspectthehydraulic-pump,jackshaft,and

crankshaftbelts(Figure174)fordamage,wear,

excessivecushioncracks,orlargeembedded

debris.

Note:Replacethebelt(s)whenneeded.

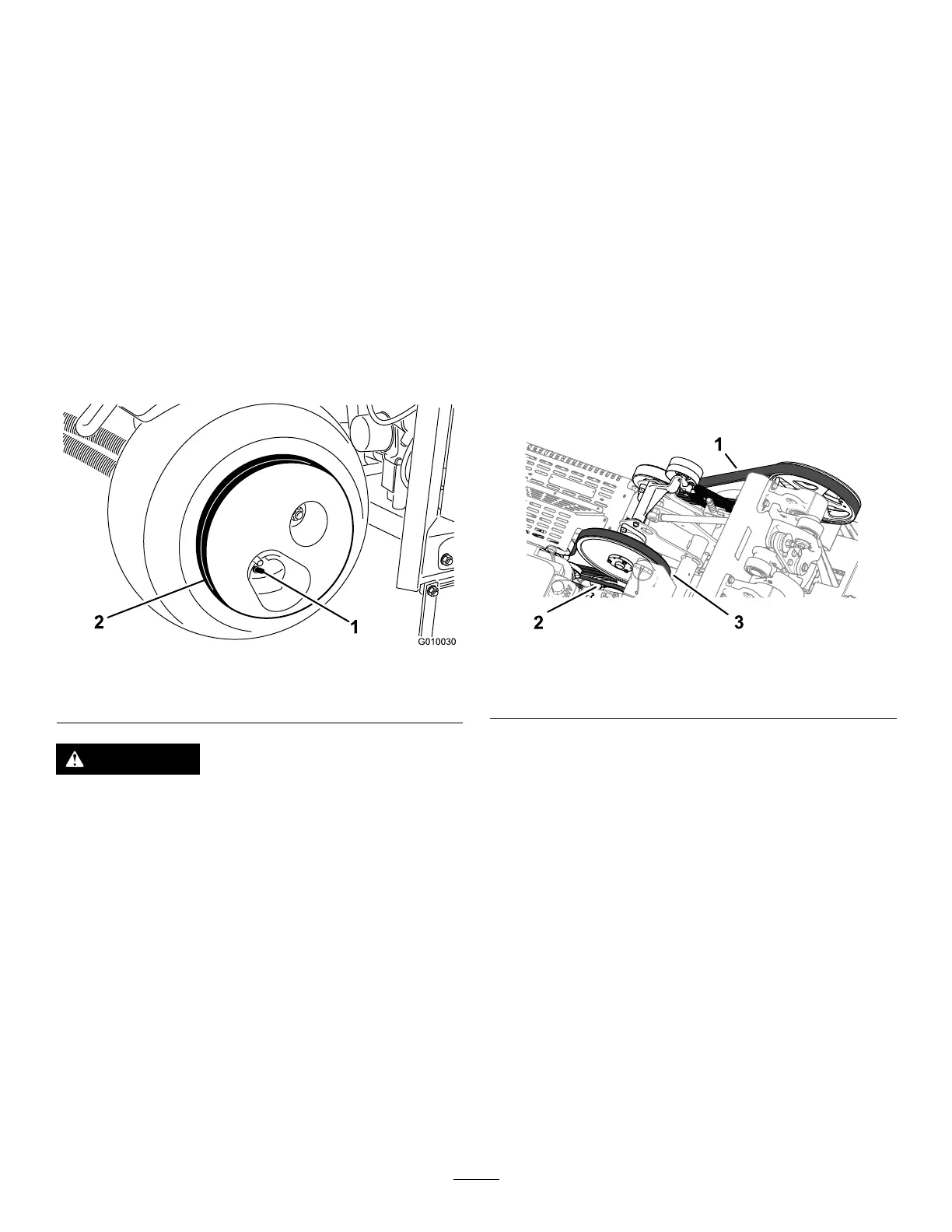

g341466

Figure174

1.Crankshaftbelt

2.Hydraulic-pump

belt

3.Jackshaftbelt

3.Installthebeltcover;refertoInstallingtheBelt

Cover(page67).

AdjustingthePumpBelt

ServiceInterval:Aftertherst8hours

1.Preparethemachineformaintenancereferto

PreparingtheMachineforMaintenance(page

65).

2.Removethebeltcover;refertoRemovingthe

BeltCover(page66).

3.Loosentheange-headcapscrewandange

locknutthatsecuretheidlerpulleyforthe

hydraulic-pumpbelt,untiltheboltmovesinthe

slotoftheidlersupport(Figure175).

79

Loading...

Loading...