B

36

Repair and Service Manual

BRAKES

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

10002660

Complete brake failure usually indicates a loss of hydrau-

lic fluid pressure.

If the brake pedal has a soft feel:

1. Bleed the brakes to remove air from the brake sys-

tem. (See BLEEDING AND FLUSHING on page 38)

A brake pedal that loses resistance indicates a leak in the

hydraulic system:

1. Check brake fluid level.

2. If the fluid is low, inspect the system for leaks.

i. Check for leaks by applying pressure to the

pedal gradually and steadily.

ii. If pedal sinks very slowly to the floor, the sys-

tem has a leak along the brake lines or at the

hydraulic cylinder. If no external leaks are

apparent, the problem is likely inside the

master cylinder

3. If leaks are found, repair the leaks in the brake sys-

tem.

4. If the master cylinder is found to be leaking, replace

it.

5. Bleed the brakes to remove air from the brake sys-

tem.

Do not allow brake fluid to contact

painted surfaces. Wipe off immedi-

ately if contact is made.

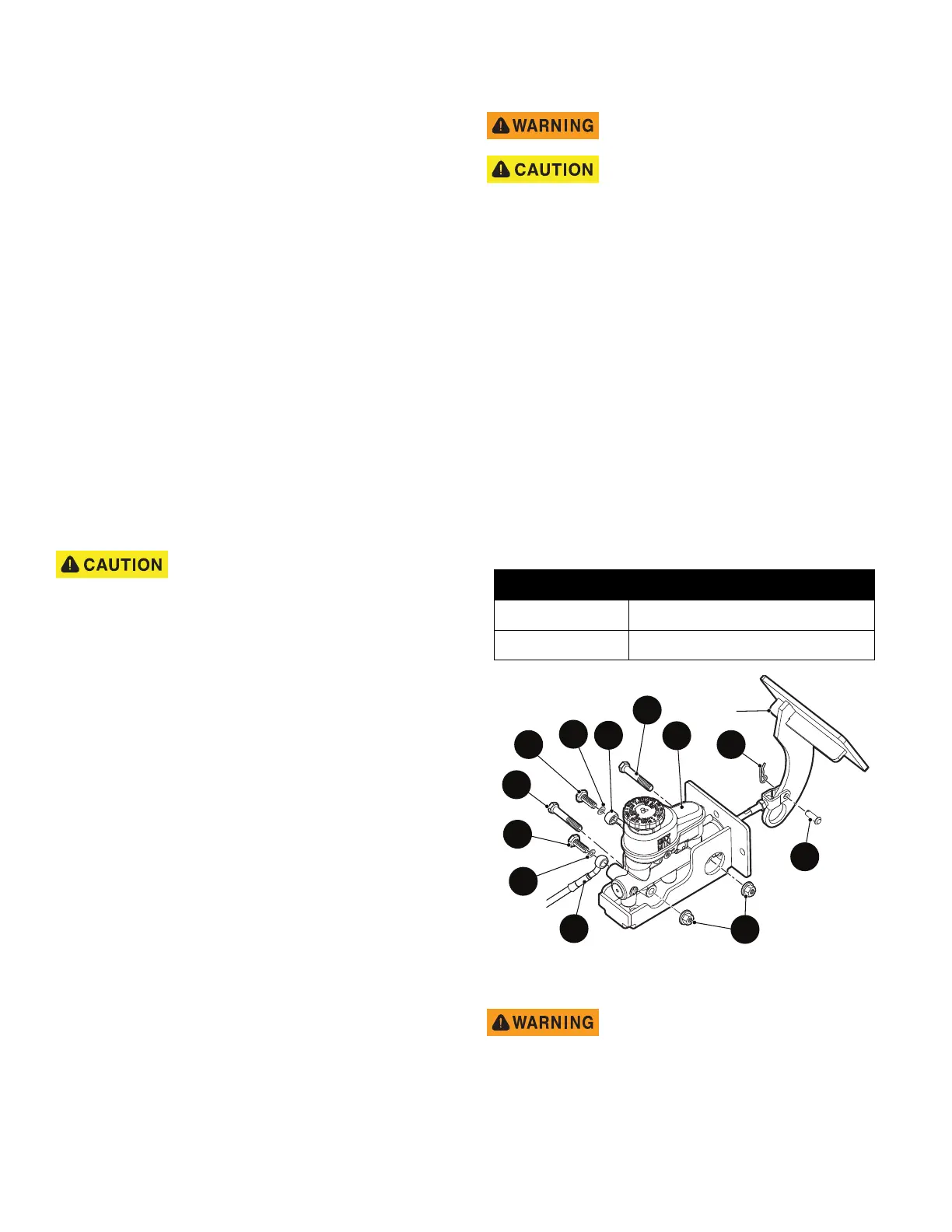

MASTER CYLINDER

The master cylinder is mounted to the frame, behind the

driver side front wheel (Ref. Fig. 1). The master cylinder

will eventually require replacement due to deterioration of

the cylinder seals (cups). Fluid will leak past the cups and

show as an external leak. A common symptom is a soft

brake pedal, meaning that it goes all the way to the floor.

The rubber parts wear or deteriorate with use, age, or

fluid contamination. Corrosion or deposits formed in the

cylinder bore that are due to moisture or dirt in the

hydraulic system may cause wear of the cylinder bore or

related parts. Do not try to remove corrosion or deposits

with a cylinder hone. If corrosion or deposits are detected

on the master cylinder, replace it with a new one and flush

the system (See Flushing on page 39).

Master Cylinder Replacement

Tool List Qty.

Insulated Wrench, 9/16” .............................................. 1

Container ..................................................................... 1

Needle Nose Pliers...................................................... 1

Wrench, 9/16” .............................................................. 2

Wrench, 1/2” ................................................................ 1

Wrench, 14mm ............................................................1

Socket, 9/16” ............................................................... 1

Socket, 1/2” ................................................................. 1

Socket, 14mm.............................................................. 1

Torque Wrench, ft. lbs.................................................. 1

DO NOT reuse crush washers.

When replacing the master cylin-

der, it is likely that brake fluid will

leak from the master cylinder. Do

not allow brake fluid to contact the painted body

components of the vehicle. Clean off immediately if

contact is made.

1. Switch the key switch into the OFF position, and

remove the key.

2. Clean the area around the master cylinder (1) to pre-

vent dirt and grease from contaminating the hydrau-

lic system (Ref. Fig. 2).

3. Remove the banjo bolts (9) and washers (10).

4. Disconnect the front brake line (7) and the rear brake

line (11) from the master cylinder (1) (Ref. Fig. 2).

Provide a container for the released brake fluid.

5. Remove the cotter pin (3) and clevis pin (4).

6. Remove two hex head bolts (2) and nuts (5).

7. Remove the master cylinder from the vehicle.

Assemble in the reverse order of removal using new

crush washers. Tighten all hardware to the torque values

specified below.

.

Fig. 2 Master Cylinder

To prevent contaminated brake fluid

causing a brake failure, never use

any excess fluid or return to the

original container. Dispose of brake

fluid properly.

Item Torque Specification

9 20 - 24 ft lbs. (27- 32 Nm)

5 13 - 17 ft. lbs. (18 - 23 Nm)

5

4

3

2

9

2

11

1

9

10

Brake

Pedal

7

10

Loading...

Loading...