B

ELECTRICAL

Read all of SAFETY and this section before attempting any procedure. Pay particular attention to Notices, Cautions, Warnings and Dangers.

49

Repair and Service Manual

10002660

ELECTRONIC SPEED CONTROL

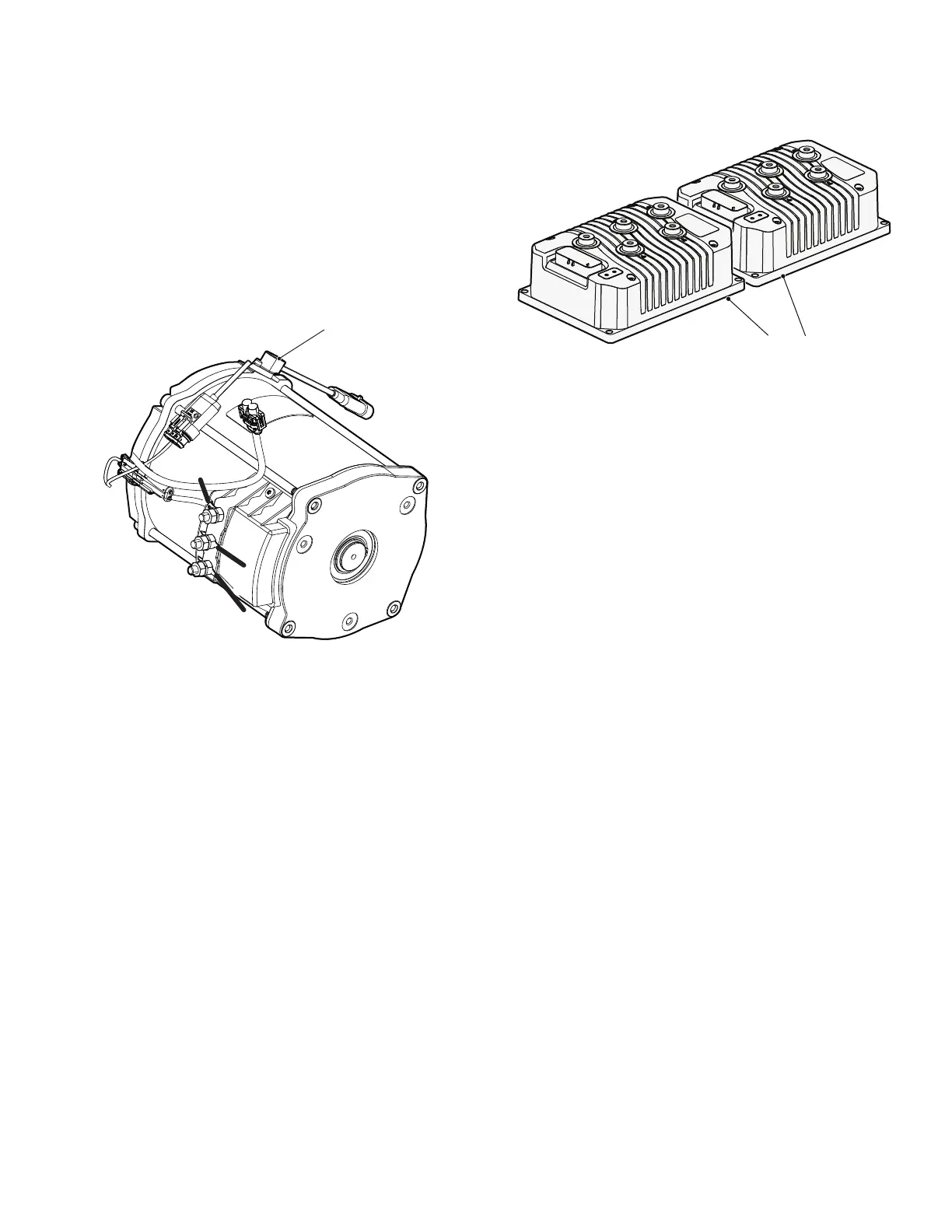

Speed Sensor

The speed sensor uses a sealed sensor to read the

impulses of a ring magnet that is attached to the armature

shaft of the motor speed sensor (Ref. Fig. 8). Magnetic

pulses change to electrical signals, which the controller

uses to determine the motor speed.

Test the speed sensor and replace if necessary (See

FAULT TESTING on page 52).

Fig. 8 Speed Sensor

Rotary Position Sensor

The rotary position sensor determines the speed of the

vehicle. The rotary position sensor is connected through

the main harness to the electronic speed control system.

With no pressure applied on the accelerator pedal, the

rotary position sensor remains in the neutral position.

When the pedal is pressed, the amount of deflection in

the rotary sensor is transferred to the electronic speed

control system. The speed control system controls the

speed of the motor that transmits power to the electric

powertrain module in the vehicle.

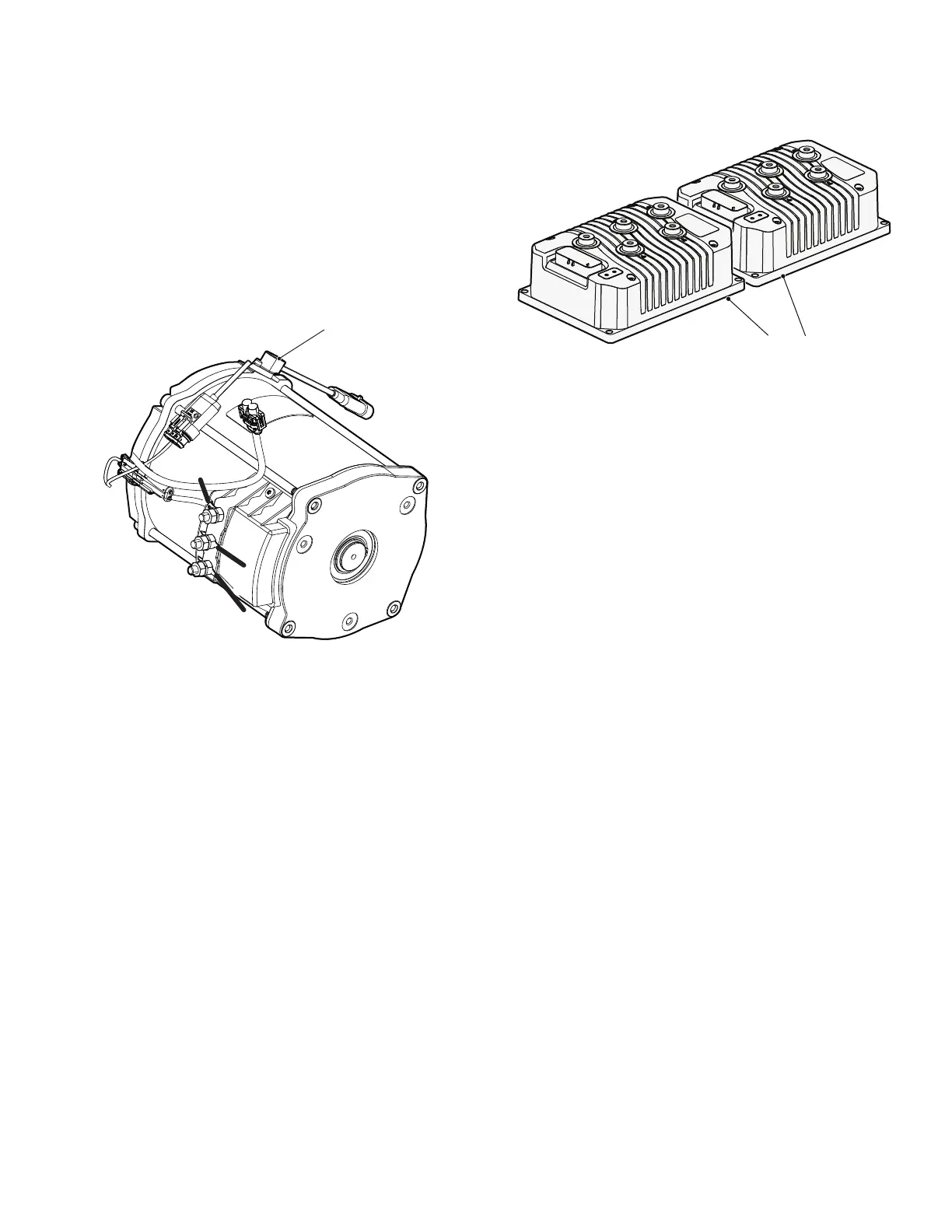

Controller

The controller is a solid state unit that activates a sole-

noid, and controls the function of the vehicle by respond-

ing to inputs from the rotary position sensor, motor speed

sensor and many other units. The controller is located

under the flip seat at the rear of the vehicle (Ref. Fig. 9).

Fig. 9 Controllers

The main wire harness, rotary position sensor, and speed

sensor are connected to the controller with a 24-pin plug.

The rotary position sensor is connected to the controller

with a 2-pin plug on the main wire harness. The speed

sensor is connected to the controller with a 3-pin plug on

the main wire harness.

The controller is connected to the batteries and creates a

regulated power supply for the rotary position sensor.

When the pedal is pressed, the amount of deflection in

the rotary sensor changes the voltage which is fed back

to the controller. The controller senses the change in volt-

age and supplies the appropriate power to the motor.

The rotary position sensor unit and the controller are both

solid state units that contain no serviceable parts. The

testing procedures test the basic functionality of the

power and control wiring systems. Once the functionality

of the wiring has been confirmed, the remaining tests are

used to identify which of the components (controller or

rotary position sensor) must be replaced.

Loading...

Loading...