TRUE ICE SERVICE MANUAL truemfg.com

TEC_TM_198 | REV. A | EN

P#857284

03/26/2024 Page 76 of 96

Troubleshooting & Diagnosis

Transducer Diagnosis

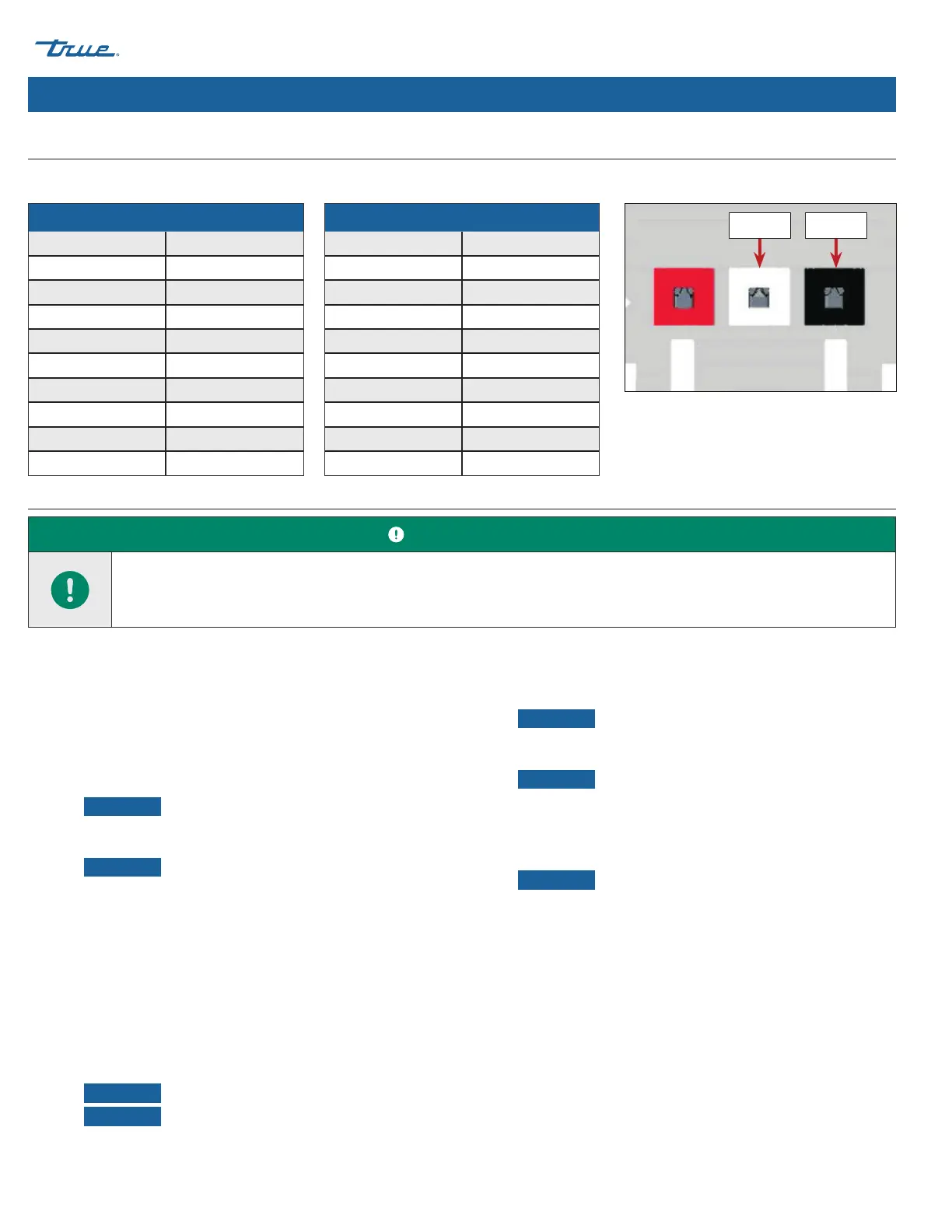

Read voltage between the black and white wires at the control board. See fig. 1

Compressor Diagnosis

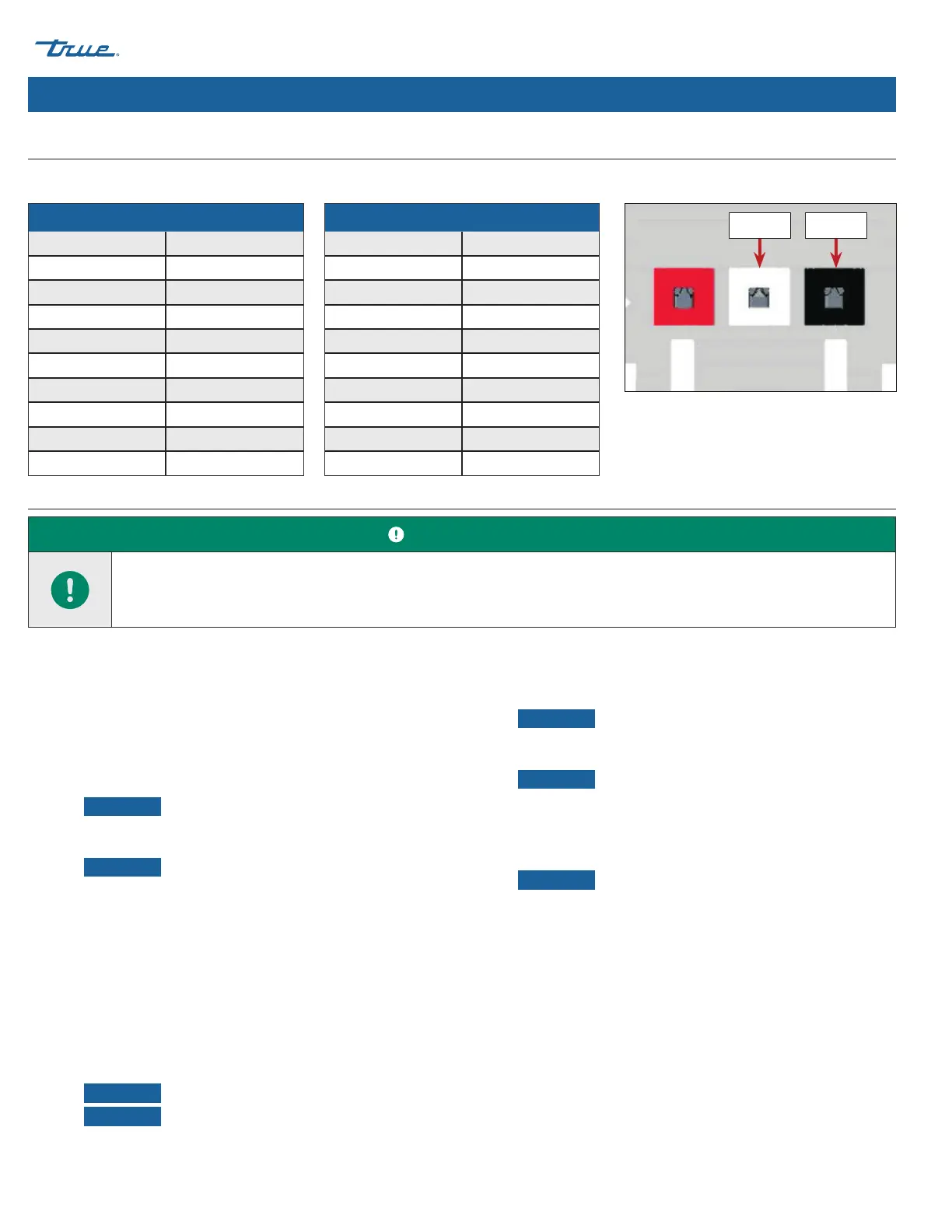

Low Pressure Transducer

VDC PSI

0.5 0

1.0 25

1.5 50

2.0 75

2.5 100

3.0 125

3.5 150

4.0 175

4.5 200

High Pressure Transducer

VDC PSI

0.5 0

1.0 50

1.5 100

2.0 150

2.5 200

3.0 250

3.5 300

4.0 350

4.5 400

Fig. 1. Measure between the black and white wires.

White Black

USER ACTION!

Do not unsolder a defective component. Cut defective components out of the refrigeration system.

1. Check the resistance between the compressor terminals.

a. Single Phase

i. Disconnect power.

ii. Remove the wires from the compressor terminals.

iii. Check the resistance between C and S, C and R, and S

and R.

NOTICE ›

When added together, the resistance values

between C and S and between C and R should equal the

resistance value between S and R

NOTICE ›

If there is a resistance reading between S and

R with open readings between C and S and between C

and R, then the overload is open.

iv. Let the compressor cool. Then, check the readings again.

b. Three Phase

i. Disconnect power.

ii. Remove the wires from the compressor terminals.

iii. Check the resistance between L1 and L2, L2 and L3, and

L3 and L1.

NOTICE ›

The resistance values should all be equal.

NOTICE ›

If there are open readings between L1 and

L2, L2 and L3, and L3 and L1, then the overload is open.

iv. Let the compressor cool. Then, check the readings again.

2. Check motor windings to ground.

a. Check continuity between all three terminals and the

compressor shell or copper refrigeration line.

NOTICE ›

If continuity is present, the compressor

windings are grounded and the compressor should be

replaced.

NOTICE ›

Scrape the metal surface to get good contact.

3. Verify compressor pulls locked rotor amps.

a. Try to start the compressor with a start cord or a correctly

sized 3N1.

NOTICE ›

Always check if the voltage drops below the

name plate voltage.

i. If the compressor starts, then replace all start components.

ii. If the compressor does not start, then replace the

compressor.

Loading...

Loading...