- 29 -

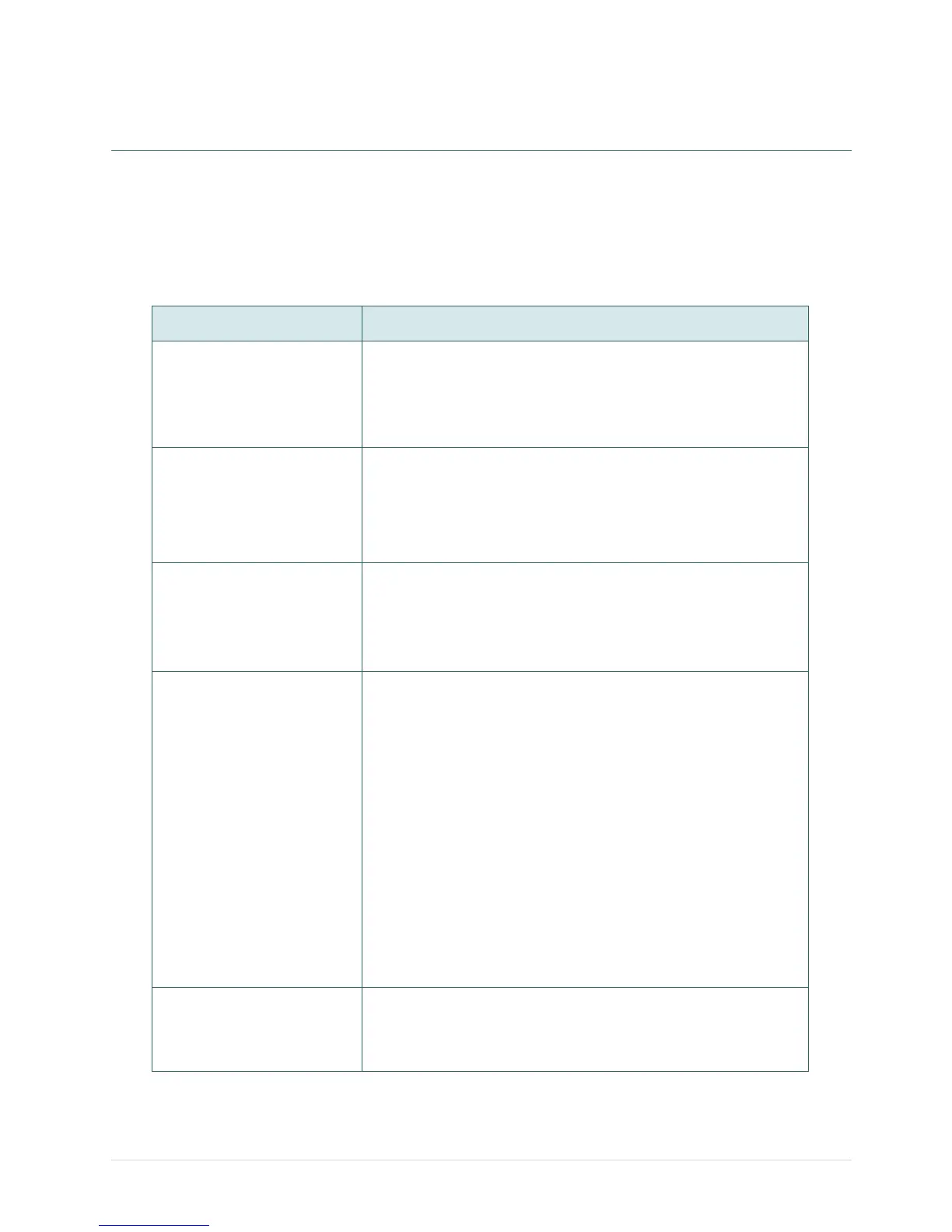

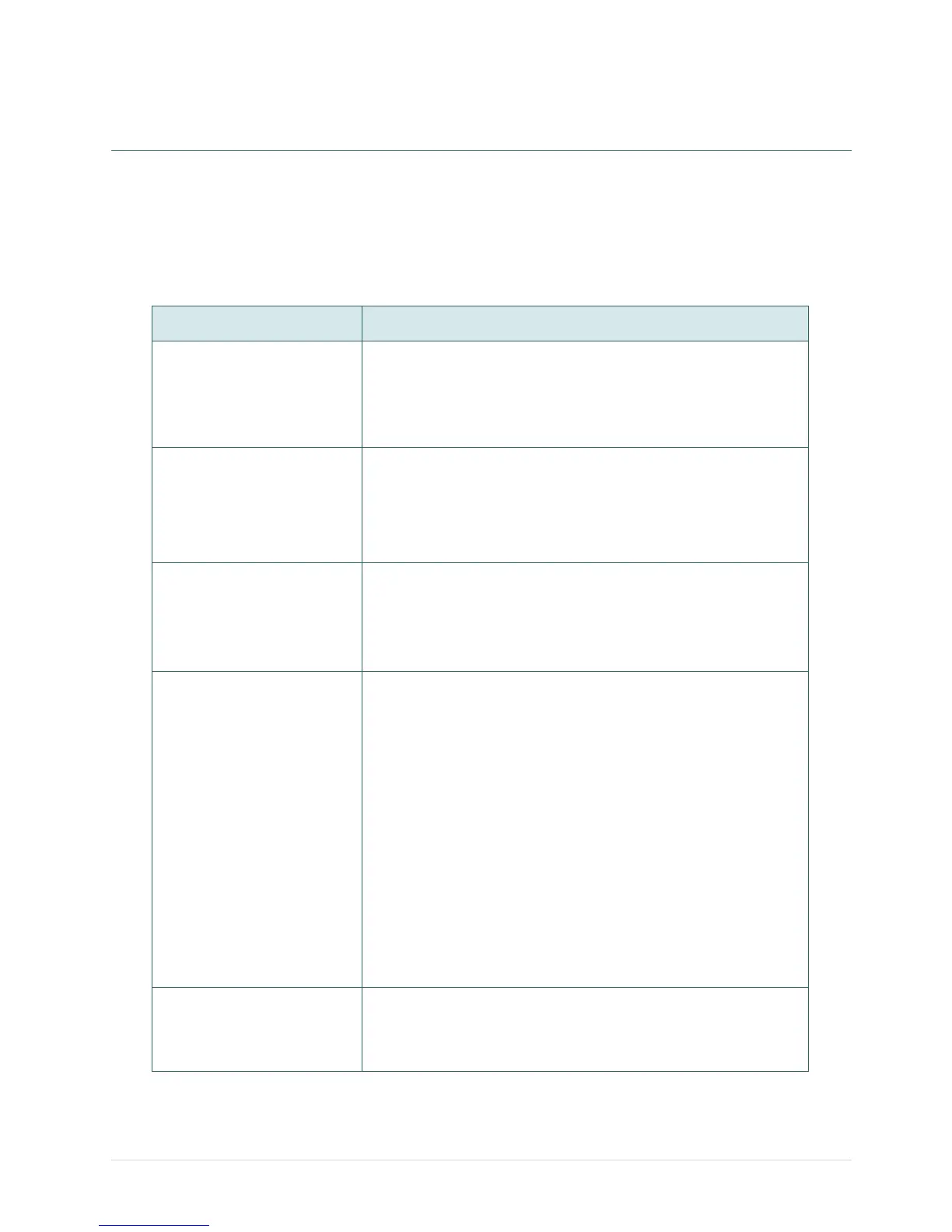

6. Troubleshooting

The following guide lists the most common problems that may be encountered when operating this

bar code printer. If the printer still does not function after all suggested solutions have been

invoked, please contact the Customer Service Department of your purchased reseller or distributor

for assistance.

Ribbon does not advance

or rewind

1. The media and ribbon must be installed then engage the

print head mechanism prior to turning on printer power.

2. Install the black ribbon spindle at the correct direction.

3. Please check the "Media settings method" in the driver if it

is set to direct thermal mode.

1. Clean the thermal print head.

2. Adjust the print density setting.

3. Ribbon and media are not compatible.

4. Media thickness is over spec.

5. Check if correct power supply is connected with printer.

Power indicator on printer

does not illuminate

1. Check the power cord see whether it is properly

connected.

2. Check if the LED on the power supply is illuminated. If it is

not lit on, then the power supply is damaged.

3. Check if correct power supply is connected with printer.

ON-LINE indicator is off,

ERR. indicator is on

1. Out of paper or out of ribbon

If there is one beep sound when printer is error, then

it's gap sensor problem. Please check the following

items.

Calibrate gap sensor or setup the paper length in

labeling software/program properly.

Install the paper at the correct

If there are two beeps sound when printer is error then

it's ribbon sensor problem. Please check the following

items.

Is outside wound ribbon is used with this printer?

Is ribbon threaded correctly in the mechanism?

Is paper core installed on the ribbon take up spindle?

2. Calibrate the sensitivity of gap sensor.

Continuous feeding when

printing labels

1. Check the driver or command script setting if sensor type

is set properly.

2. Calibrate the gap sensor again if die cut media is used for

printing.

Loading...

Loading...